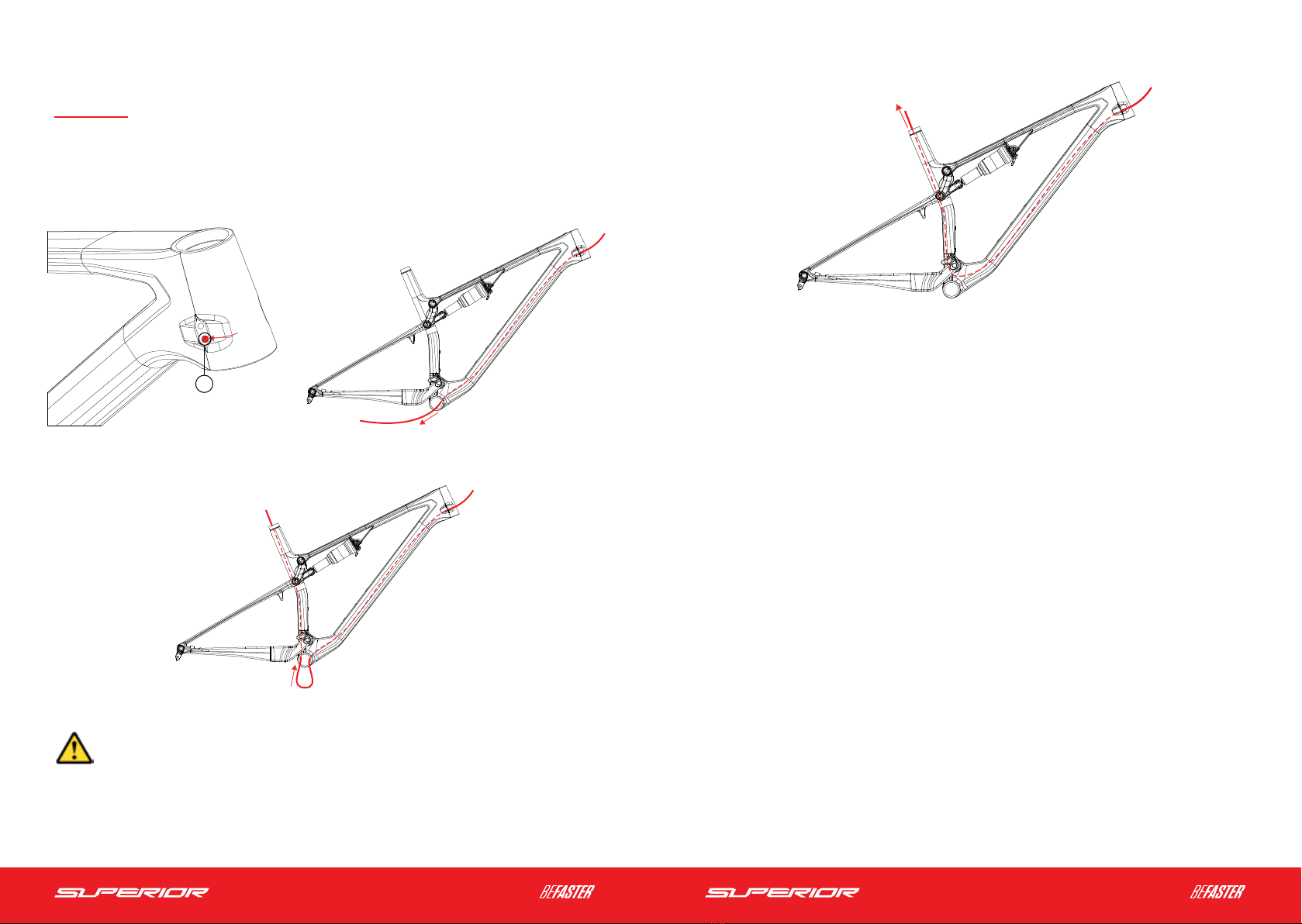

• Avoid contact with hard or sharp items. Do not rest your bike with the top tube of the frame against a column

or corner of a building.

• When xing the wheel, place the entire bike in a stand and clamp the seatpost and avoid high side loads; this

especially applies when replacing the bottom bracket and cranks/crankset. High loads can lead to damage

of the seatpost or frame.

• When transporting the bike on a car, use a bike carrier that xes the bike using the seatpost or front wheel

axle. Do not x the bike to the frame.

• Frames are not suitable for use on stationary bicycles xed to the

rear stay. The bike then cannot move, which leads to excessive load

on the end of the frame. This can cause damage to the frame.

• The frame is not suitable for the xture of any children's seats or

carriers.

• If you are transporting the bike in a box, make sure that the bike is

kept safe, for instance by using a soft foam cover. Make sure that

there are no foreign items or that excessive pressure or force from

these items cannot damage the frame. Please keep in mind that the warranty does not apply to damage

caused during transit.

• Neither the frame nor the carbon components can ever come in contact with high temperatures such as those

used in the case of powder spraying or cauterizing varnish. Such temperatures can damage the frame and

components. Also avoid leaving the bike in a car in case of strong solar radiation. Similarly, do not keep your

bike in the vicinity of sources of high temperatures.

SUPERIOR SERVICE

MANUAL

Superior would like to congratulate you on the purchase of your new bicycle. We place great emphasis on the choice

of materials and their processing so as to ensure the highest quality of our products, a long service life and great

functionality.

The Service Manual contains and species certain rules that should be followed if you want to enjoy your high-

quality Superior product for many years to come. You have received the Operating Manual with your bike.

Superior supplies high-quality bicycles exclusively for specialized shops. These products are already partially pre-

assembled.

The nal assembly of a bike for riding can only be carried out by an authorized Superior dealer. This particularly

applies to the basic conguration of suspension components, the front and back derailleurs and braking systems.

This will ensure maximum safety when using the product.

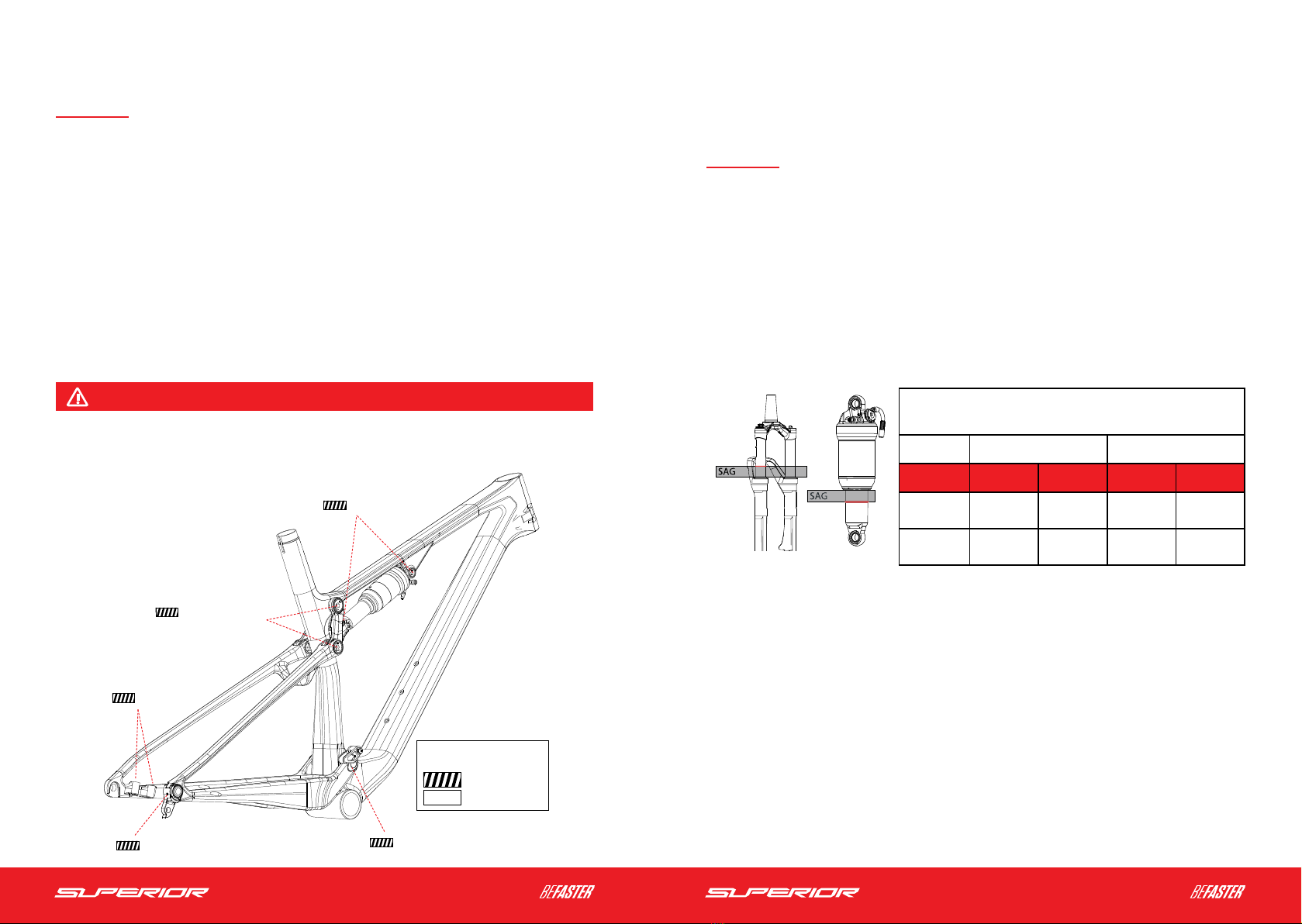

WARNING

WARNINGS RELATED TO

MECHANICAL WORK

Specialized skills and tools are required to

congure and tune the bike. These tasks should

only be carried out by employees at an authorized

service station. Riding a bike which has not been

correctly congured and assembled can be

dangerous. Even a seemingly trivial deciency,

such as a loose screw, can cause a crucial part to

break over time and the loss of control of the bike,

leading to an accident. Therefore, we recommend

that you leave any repairs and maintenance for

your bicycle to an authorized service centre. Your

safety depends on the correct maintenance of the

bike. Employees of authorized service stations

have special qualications and know-how.

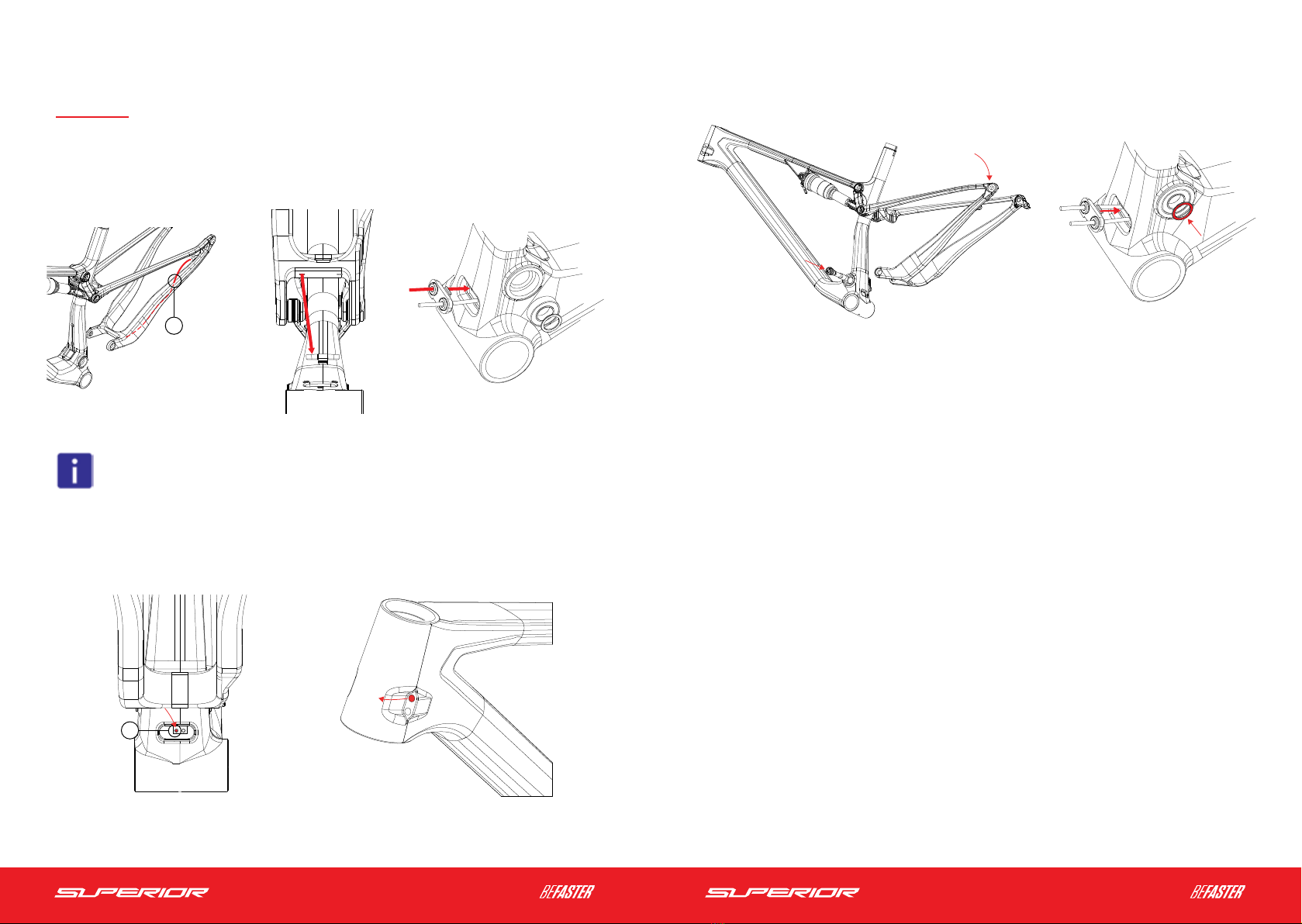

WARNING

Any adjustments and modications can lead to

the frame, fork or other parts becoming unsafe.

The use of an unapproved component or the

incorrect assembly of parts can lead to excessive

wear and tear of the bike or its parts. Adjustments

to the frame, fork or other components can have

a negative impact on the handling of the bike and

may lead to a fall. Do not grind off, drill or le any

parts, do not remove backup safety elements, do

not install incompatible forks and do not make

any other similar unauthorized changes. Before

you install any accessories on your bicycle, or

replace any part, always consult the authorized

service center to make sure the particular

accessory or part is compatible and safe to use.

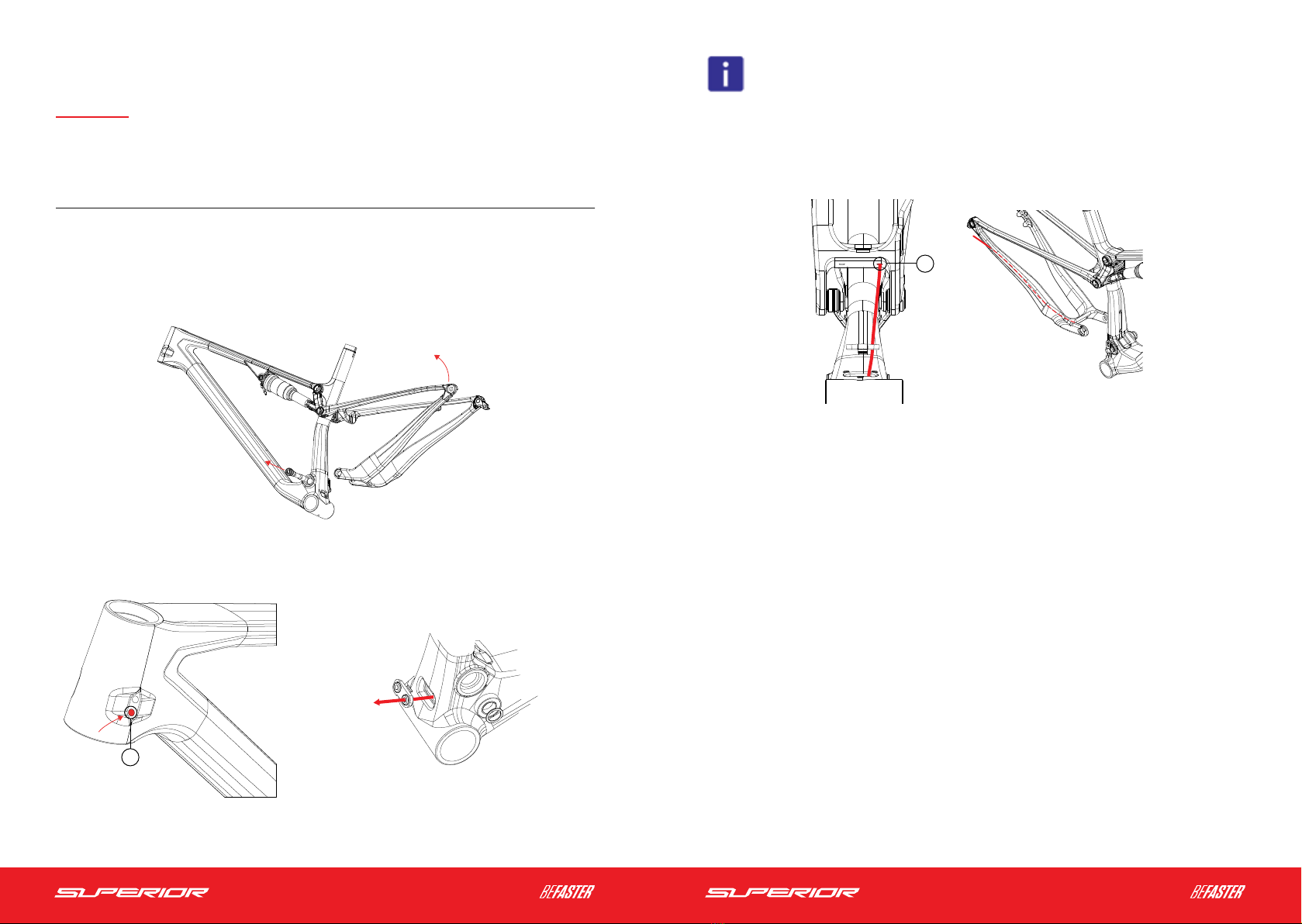

Type-3 operating conditions

Riding on paved roads, on- and offroad with drops, rough trails, rough unpaved roads,

and rough terrain and unimproved trails that require technical skills. Jumps and drops

are intended to be less than 61 cm (24'')

BIKE CATEGORY

PREVENTION OF DAMAGE

Mountain bikes are equipped with a rear suspension with short travel and are constructed for “standard,” “racing”,

“cross-country” or “singletrack-trail” rides, assuming adherence to type-3 operating conditions: