3.2 How to determine the direction of liquid flow in the pipeline ................... 20

3.3 How to change the measurement unit system ........................................ 20

3.4 How to select the flow unit ...................................................................... 20

3.5 How to select the accumulator multiplier .................................................20

3.6 How to open and close the accumulator .................................................20

3.7 How to zero the flow accumulator ...........................................................21

3.8 How to restore factory settings ................................................................21

3.9 How to use the damper to stabilize the flow display ............................... 21

3.10 How to use zero cut to avoid invalid accumulation ............................... 21

3.11 How to statically calibrate the zero point ...............................................21

3.12 How to modify the meter coefficient (scale factor) calibration calibration21

3.13 How to use password protection ........................................................... 22

3.14 How to use the built-in data logger ........................................................22

3.15 How to use the frequency output function .............................................22

3.16 How to set the cumulative pulse output ................................................ 23

3.17 How to generate the output alarm signal I ............................................ 23

3.18 How to use the buzzer .......................................................................... 24

3.19 How to use the OCT output ...................................................................24

3.20 How to change the date and time ......................................................... 24

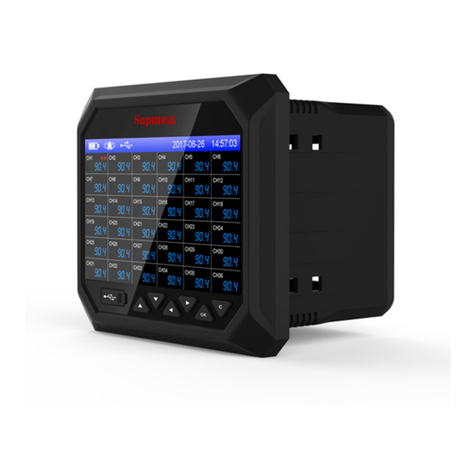

3.21 How to adjust the contrast of the LCD monitor ..................................... 24

3.22 How to use RS232/RS485 serial port ................................................... 24

3.23 How to check the daily, monthly and yearly traffic ................................ 24

3.24 How to use the work timer .....................................................................24

3.25 How to use the manual accumulator .....................................................25

3.26 How to view the electronic serial number and other details .................. 25

3.27 How to know the operating time of the remaining battery power .......... 25

3.28 How to charge the battery ..................................................................... 25

Chapter 4 Menu window Details ............................................................................26

Chapter 5 Troubleshooting .................................................................................... 33

5.1 Power.on Error Displays and Counter.Measures ....................................33

5.2 Error Code and Counter.Measures .........................................................34

5.3 Other Problems and Solutions ................................................................ 35