Contents

Chapter 1 Safety instructions............................................................................................ 1

1.1. Manufacturer's safety Instructions...................................................................... 1

1.1.1. Copyright and data protection...................................................................... 1

1.1.2. Exemption clause...........................................................................................1

1.1.3. Product liability and warranty....................................................................... 2

1.1.4. Document details............................................................................................2

1.1.5. Display convention......................................................................................... 3

1.2. Safety instructions for operators......................................................................... 3

Chapter 2 Introduction........................................................................................................ 4

2.1. Scope of delivery................................................................................................... 4

2.2. Measuring principle............................................................................................... 6

2.3. Mechanical Construction...................................................................................... 7

2.4. Application introduction.........................................................................................8

2.5. Wiring introduction.................................................................................................9

2.6. Nameplate............................................................................................................ 11

Chapter 3 Installation........................................................................................................12

3.1. Installation tips..................................................................................................... 12

3.2. Storage..................................................................................................................12

3.3. Pipeline design.....................................................................................................12

3.4. Pipe design...........................................................................................................12

3.5. Installation conditions......................................................................................... 15

3.6. Mechanical installation....................................................................................... 19

3.6.1. Installation of flowmeter pipeline............................................................... 19

3.6.2. Precautions................................................................................................... 20

3.6.3. Installation of flowmeter.............................................................................. 22

3.7. Dimensions for electromagnetic flowmeter..................................................... 23

Chapter 4 Electrical connection...................................................................................... 25

4.1. Safety tips............................................................................................................. 25

4.2. Connect signal and magnetic field current cable........................................... 25

4.3. Potential Equalization......................................................................................... 27

4.4. Power supply........................................................................................................27

4.5. Output termination...............................................................................................29

Chapter 5 Start up.............................................................................................................31

5.1. Power on...............................................................................................................31

5.2. Converter start up................................................................................................31

Chapter 6 Operation......................................................................................................... 32

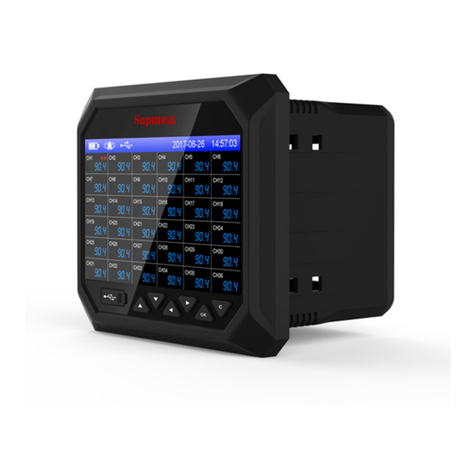

6.1. Display and operating elements........................................................................32