Chapter 1 Product information

www.supmea.com

Content

Chapter 1 Product information..................................................................................... - 8 -

1.1 Product Overview........................................................................................ - 8 -

1.2 Product appearance....................................................................................- 8 -

1.3 Product characteristics............................................................................... - 9 -

1.4 Working principle......................................................................................... - 9 -

1.5 Technical parameters............................................................................... - 10 -

Chapter 2 Installation...................................................................................................- 11 -

2.1 Overview.....................................................................................................- 11 -

2.2 Open............................................................................................................- 11 -

2.3 Fixed............................................................................................................- 12 -

2.4 Water supply.............................................................................................. - 13 -

2.5 Power supply............................................................................................. - 14 -

Chapter 3 Data interface.............................................................................................- 15 -

3.1 Overview.....................................................................................................- 15 -

3.2 485Modbus interface................................................................................ - 15 -

3.2.1 Wiring mode.................................................................................. - 15 -

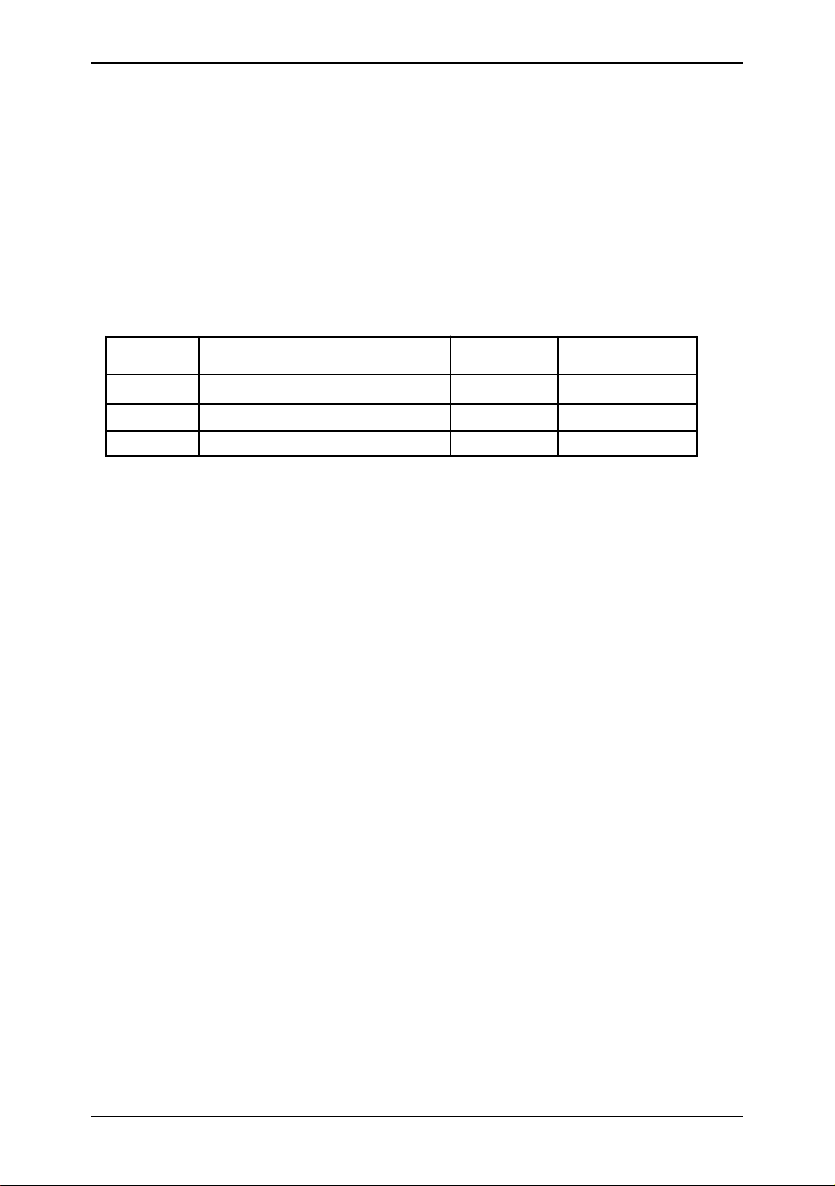

3.2.2 485 baud rate................................................................................ - 15 -

3.2.3 Modbus Agreement...................................................................... - 15 -

3.3 4-20 mA Interface (optional)485Modbus interface...............................- 17 -

Chapter 4 Operationmaintenance................................................................................. - 18 -

4.1. Operating Panel.......................................................................................... - 18 -

The operation panel function definition is shown below...............................- 18 -

4.2 Fault analysis............................................................................................. - 18 -

Table 5 Causes of failure...................................................................................- 19 -

4.3 Maintenance...............................................................................................- 19 -

4.4.Field calibration............................................................................................ - 19 -

4.5.After-sales service....................................................................................... - 20 -