Sure-Feed Engineering ECO Series Application guide

Sure-Feed Engineering Inc.

SE-1200-EI

ECO-SERIES

Operation & Parts Manual

Sure-Feed

Engineering

Inc

1

SE 1200 EI

ECO-SERIES

OWNERS MANUAL

Table of Contents

1. Installation guide

2. Set-up instructions

3. Operation instructions

4. Cleaning

5. Troubleshooting

6. Parts manual

7. Electrical schematic

8. Warranty information

Sure-Feed

Engineering

Inc

2

SECTION 1

Sure-Feed Engineering Inc.

Installation Instructions

1. Before positioning the feeder on the inserter, follow the setup and

operating instructions completely. When you are confident the material

is feeding consistently, precede to the inserter preparation instructions

then the installation and set-up procedure.

2. Remove the rear guide from the inserter pocket.

3. Remove the bottom plate.

4. Remove the suction cup and loosen the separator feet, sliding them back and

to the furthest point sideways so as not to interfere with the path of the piece

to be inserted.

5. Cycle the inserter to the point where the gripper jaw is at the furthest point

forward in the stroke.

6. Bend the material guide tabs so that they align just above the surface of the

bottom gripper jaw.

7. Adjust the 3-leg sensor arm to position the sensor 1/2” above the paper path

and about 3/4 of the length of the piece ahead of the feeder.

8. Place 10 pieces in the feeder and turn the speed adjustment to the minimum

setting (counter-clockwise).

9. Plug the feeder into a 110 VAC grounded outlet.

10.Turn the power switch on.

11.By turning the speed control switch clockwise, advance the first piece until the

sensor is blocked and the feeder stops. If the sensor is not positioned

properly, the feeder will not stop. Adjust the height and angle of the sensor

until the feeder stops.

Sure-Feed

Engineering

Inc

3

Sure-Feed Engineering Inc.

Installation Instructions Cont’

12.Position the feeder on the inserter table so that the edge of the leading piece

is between the material guide tabs and the bottom of the front hopper plate.

13.Adjust the sensor so that the piece advances out further and is well within the

gripper jaw opening.

14.With the speed control set to minimum, jog the inserter to remove the piece

staged in the gripper jaw and return the gripper jaw to the furthest inward

position.

15.Turn the speed control up slightly. This should advance the next piece into

the gripper jaw. Adjust the sensor, material guide tabs and position the SE

1200 EI (Eco-Series) as needed to align the paper path into the gripper jaw.

16.Load the SE 1200 EI (Eco-Series) with at least a full handful of material and

cycle the inserter.

17.Notice the material path and the presentation to the gripper jaw, as this is

most important as the cycle speed is increased.

18.Cycle the inserter at full production speed adjusting the SE 1200 EI (Eco-

Series) speed so that the piece being presented to the gripper jaw is there

well ahead of the end of the forward stroke.

Sure-Feed

Engineering

Inc

4

SECTION 2

Sure-Feed Engineering Inc.

Set-up Instructions

1. With the feeder ON/OFF switch in the off position, loosen the two side guides

and move them all the way to the sides of the feeder. Then loosen the rear

guide ramp and move it all the way back out of the way.

2. Place a single piece of the material to be fed on the feeder centering the

material relative to the separating device.

3. Move each side guide in to meet the material and then back them off about

1/16”.

4. Tighten the bottom thumbscrews on each side guide.

5. Turn the separator knob clockwise until you can easily pass the single piece

of material under the separator. While moving the material back and forth

under the separator, turn the separator knob counter-clockwise until you feel

resistance from the separator. At this point, you have roughed in the

separator setting and will need to tune it in after the completion of the

following set-up steps. If the resistance under one separating wheel is not the

same as under the separating wheel, the bridge needs to be trammed.

Perform step 10 before proceeding with step 6.

6. Place a handful of material in the feeder allowing the material to shingle

forward into the separator.

7. Move the back guide forward so as to use the back guide wedge shape to

support the back edge of the material stack. At this point, you have roughed

in the back guide setting and will need to tune it in later.

8. Add enough material to the stack to fill about half the height of the side

guides.

9. Move the top of each side guide out slightly so as to create a funnel effect

and then tighten the top thumbscrews on each side guide. You are now ready

to feed some material.

Sure-Feed

Engineering

Inc

5

10.BRIDGE TRAM PROCEDURE: It is critical to the performance of the feeder

to have the separating wheels level with respect to the nip rollers. To do this,

first loosen the bridge mounting screws (Item 8, Fig. 6-3) on both sides of the

bridge. Turn the separator adjustment CW several turns so that the bridge

can be lowered all the way to the bottom of the slots. Tighten one screw on

each side. Now place a thin strip of paper under each separating wheel (it is

best to cut one piece of paper into two strips to ensure that the strips are the

same thickness). Now turn the separator adjustment CCW until the

separating wheels just contact the nip rollers. Move the paper strips to feel if

the resistance is equal under each separating wheel. If one moves with less

resistance than the other, loosen the screw on the side that is tighter and

raise that side of the bridge slightly and tighten screw. Check the resistance

under each separating wheel with the paper strips again and adjust

accordingly. Once the resistance is equal under each separating wheel

tighten the bridge screws securely. Proceed to step 6 for further setup

instructions. This procedure must be followed whenever the bridge is

adjusted up or down for materials with different thickness. This adjustment is

“very” critical when feeding thin materials.

Sure-Feed

Engineering

Inc

6

SECTION 3

Sure-Feed Engineering Inc.

Operation Instructions

1. Adjust the 3-leg sensor arm to position the sensor 1/2” above the paper path

and about 3/4 of the length of the piece ahead of the feeder.

2. With the power still off, turn the speed control counter-clockwise to the

minimum position.

3. Turn the power switch on and turn the speed control switch clockwise, the

first piece will advance until the sensor is blocked and the feeder stops. If the

sensor is not positioned properly, the feeder will not stop. Adjust the height

and angle of the sensor until the feeder stops.

4. Cycle the feeder by removing the piece that block the sensor. Observe the

consistency in which the material is feeding.

5. By turning the separator knob slightly in either direction, you will change the

way the material is separating.

6. By moving the back guide in and out, you will quickly find the position that

creates the most consistent separation.

7. One important item to note; There is no substitution for experience. By

working with the SE 1200 EI (Eco-Series), you will notice that the combination

of separator setting and the back guide adjustment together will have the

greatest effect on separation. Generally, the longer the piece of material, the

flatter the material stack should be. Conversely, the shorter the piece of

material, the closer the back guide adjustment should be to the material,

adding wedge to the material stack. You will also notice that by moving the

back guide forward (increasing the wedge), you can open the separator and

still achieve good separation.

Sure-Feed

Engineering

Inc

7

SECTION 4

Sure-Feed Engineering Inc.

Cleaning Instructions

Clean rollers and belts are very important to the performance of the feeder. Use

a clean rag dampened with Isopropyl Rubbing alcohol, 70% by volume (typically

available in drug stores) to clean belts and rollers. Do not use any other solvents,

cleaners, or abrasive cleaners on the rollers or belts as they may damage the

rubber.

Warning: Isopropyl rubbing alcohol is very flammable! Always unplug

the machine before cleaning belts and rollers. DO NOT! use near an open

flame, sparks, or any other source of ignition. DO NOT! smoke in the

vicinity of the alcohol fumes. Allow used rags to air-dry before throwing

them in the trash. Dispose of used rags properly.

Other areas of the machine should be wiped clean with a clean dry rag.

Sure-Feed

Engineering

Inc

8

SECTION 5

Sure-Feed Engineering Inc.

Troubleshooting Guide

Problem

Solution

Feeder will not run.

Check circuit breaker condition.

Check outlet power source.

Check power switch.

Feeder runs but no material is being

dispensed.

Check material supply.

Remove all material and follow setup

procedure.

Check rollers and belts for excessive

wear or dirt.

Feeder does not create a gap

between pieces.

Lower separator adjustment and

observe. If a gap is not present after this

adjustment, return separator to original

position and move the back guide

forward.

Feeder does not detect material.

Adjust position of the sensor.

Thick material does not feed well.

Decrease the height at the back of the

material stack.

Increase the opening at the separation

device (the thicker the material the less

critical the setting is).

Sure-Feed

Engineering

Inc

9

Sure-Feed Engineering Inc.

Troubleshooting Guide Cont.

Problem

Solution

Thin material does not feed.

Adjust separation device as described in

section 2.

Remove material and fan the stack

allowing air to separate the pieces.

Raise the rear of the material stack by

moving the wedge forward.

Material feeds double.

After confirming set up is correct,

remove the separator and inspect the o-

rings. If the o-rings are worn past the

depth of the groove in the separating

wheel, they will not be effective. Rotate

the o-ring in the groove until a new

section of o-ring is in position to contact

the material. Reinstall the separator and

reset the gap.

Sure-Feed

Engineering

Inc

10

SECTION 6

Sure-Feed Engineering Inc.

Parts Manual

Sure-Feed

Engineering

Inc

11

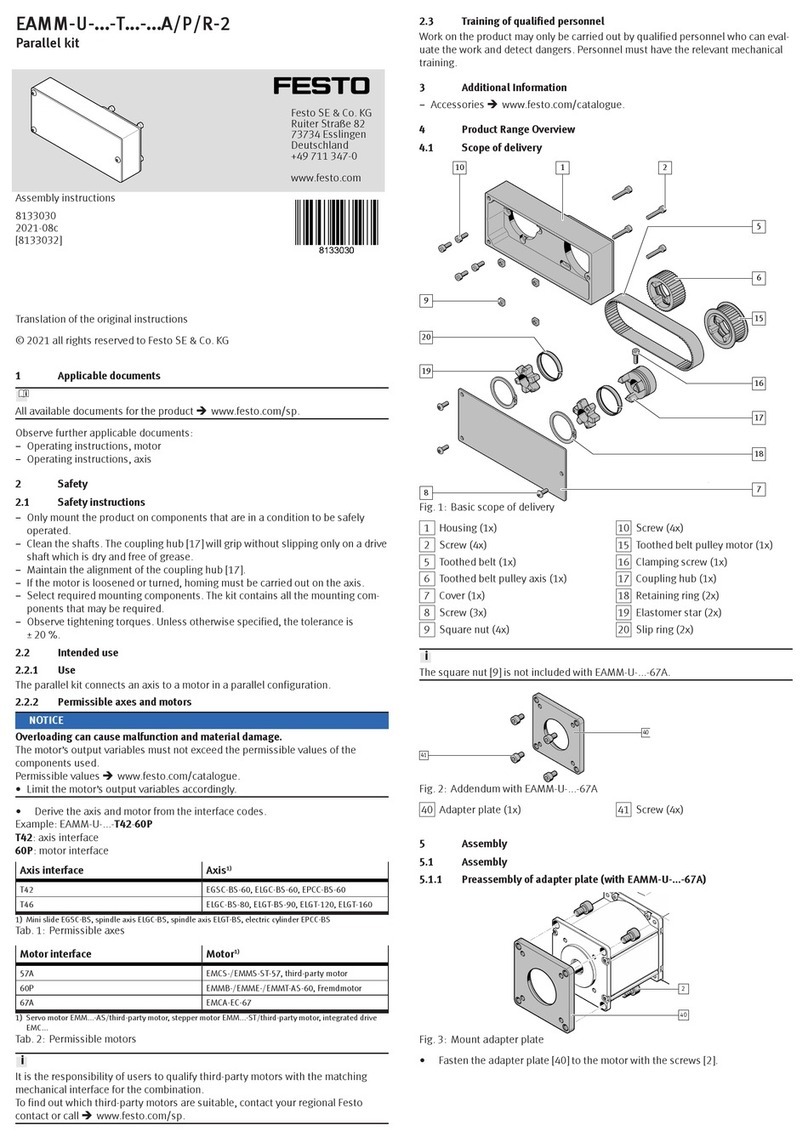

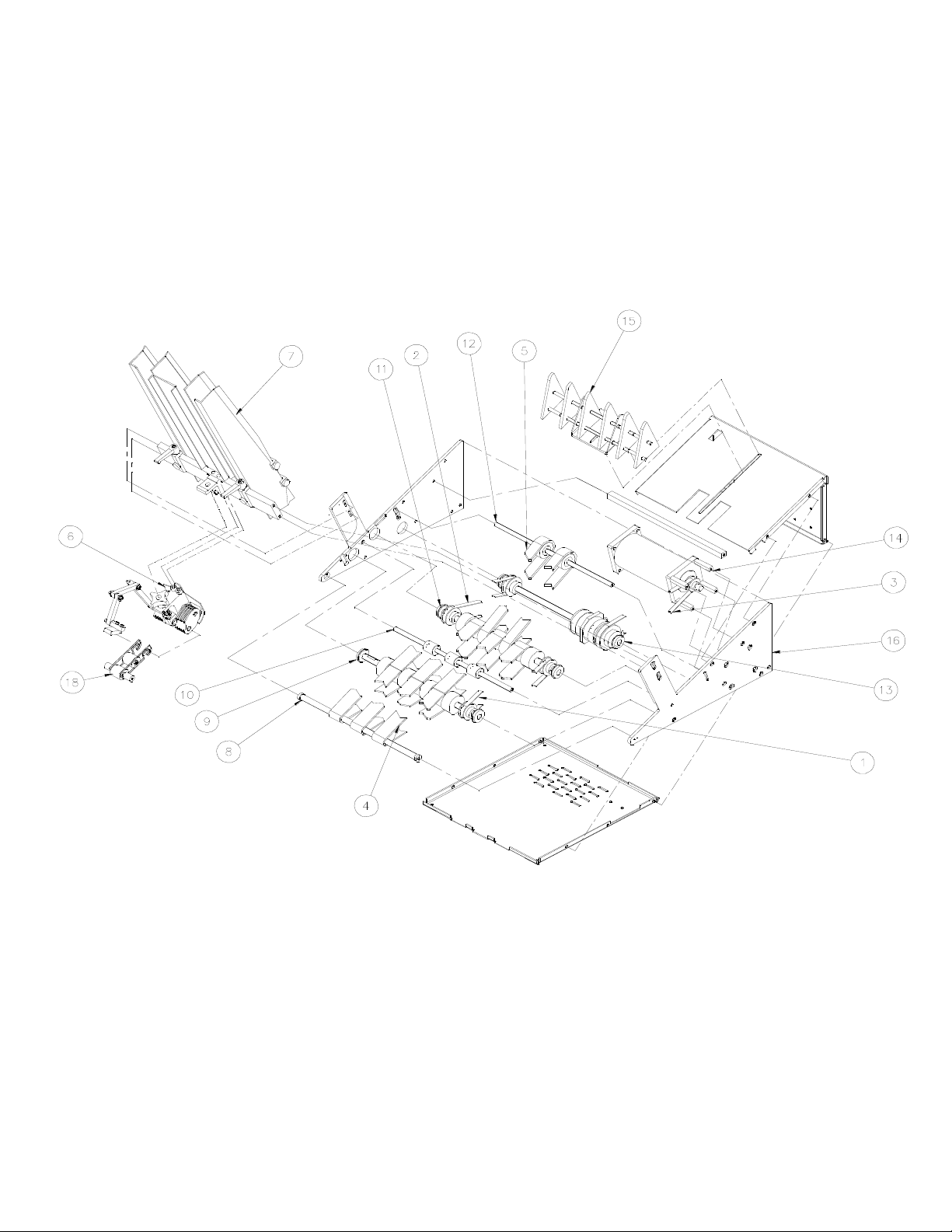

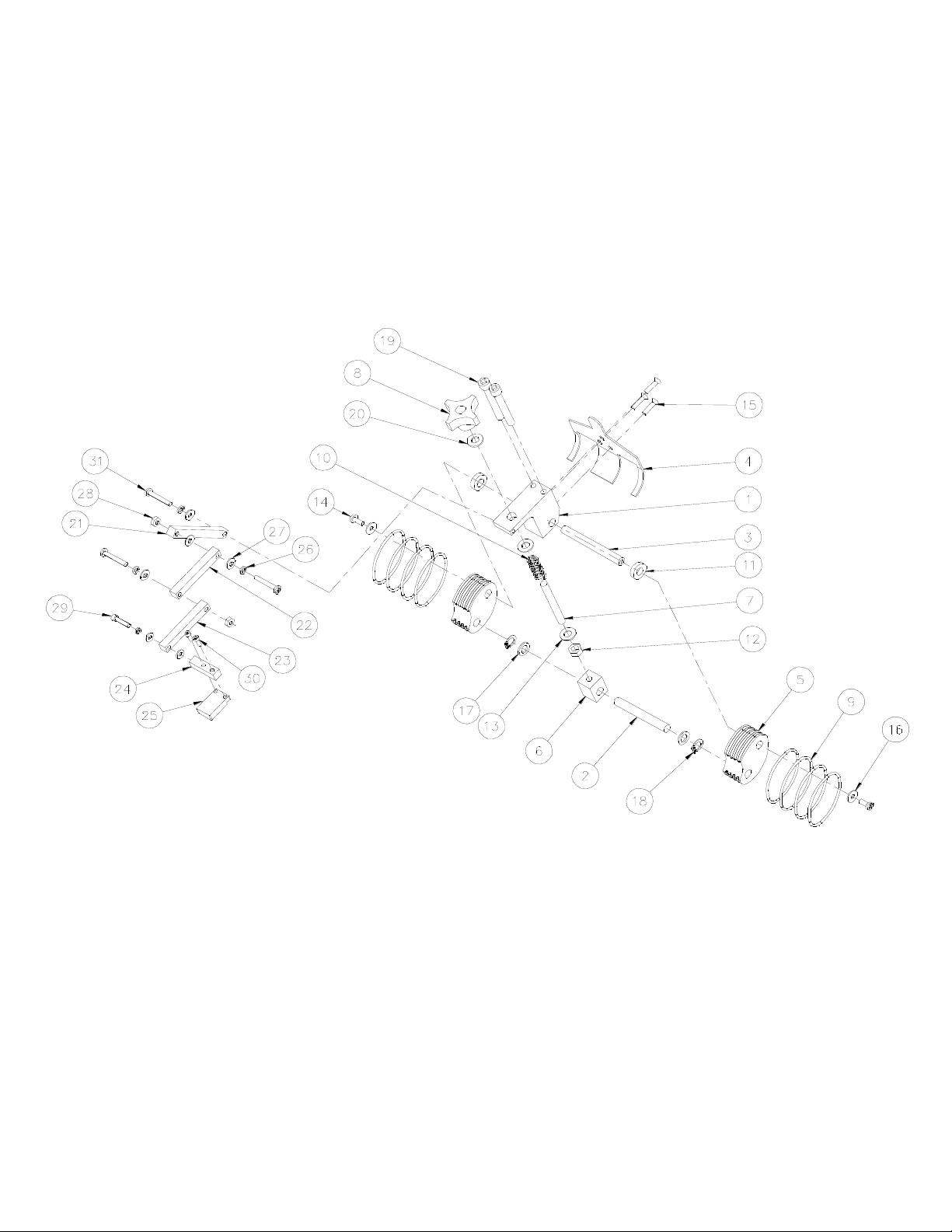

FEEDER ASSEMBLY (fig. 6-1)

ITEM

FIGURE

QTY.

DESCRIPTION

1

99000-001

1

BELT, TIMING, 90XL

2

99000-002

1

BELT, TIMING, 110XL

3

99000-003

1

BELT, TIMING, 120XL

4

99000-004

3

BELT, RED GUM

5

99000-005

2

BELT, ELEVATOR

6

6-2

1

SEPARATOR DEVICE ASSEMBLY (ECO-SERIES)

7

6-3

1

SIDE GUIDE ASSEMBLY

8

6-4

1

FRONT SHAFT ASSEMBLY

9

6-4

1

NIP ROLLER SHAFT ASSEMBLY

10

6-4

1

SUPPORT IDLER SHAFT ASSEMBLY

11

6-4

1

MAIN SHAFT ASSEMBLY

12

6-5

1

ELEVATOR SHAFT ASSEMBLY

13

6-6

1

CLUTCH SHAFT ASSEMBLY

14

6-6

1

MOTOR ASSEMBLY

15

6-7

1

PAPER SLIDE ASSEMBLY

16

6-8

1

CHASSIS ASSEMBLY

17

6-9

1

ELECTRICAL COMPONENT ASSEMBLY (NOT SHOWN)

18

6-10

1

TRAILING ARM ASSEMBLY

Sure-Feed

Engineering

Inc

12

FIG. 6-1

Sure-Feed

Engineering

Inc

13

1200EI-ECO SEPARATOR DEVICE ASSY (Fig. 6-2)

ITEM

PART NO.

QTY.

DESCRIPTION

1

10007-002

1

BLOCK, FOOTBALL SEPARATOR

2

10004-059

1

SHAFT, FOOTBALL ALIGNING

3

10004-058

1

SHAFT, FOOTBALL SEPARATOR

4

10005-025

1

SHROUD, SEPARATOR

5

10007-005

2

BLOCK, FOOTBALL.

6

10007-012

1

BLOCK, SEPARATOR ADJUSTING

7

10004-028

1

STUD, SEPARATOR ADJUSTING

8

99004-001

1

KNOB 5/16-24 FE

9

10014-010

8

O-RINGS, FOOTBALL SEPARATOR

10

10019-002

1

SPRING, COMPRESSIOM (FOOTBALL)

11

10012-005

2

SPACER, FOOTBALL SEPERATOR

12

1

NUT, HEX 5/16-24

13

2

WASHER, FLAT 5/16

14

2

SCREW, PAN HD 10-24 X 3/8

15

3

SCREW, FL HD 8-32 X 1

16

2

WASHER, FLAT, #10

17

99003-017

2

WASHER, NYLON 3/8 ID X 1/16

18

99022-003

2

SNAP RING, 3/8

19

2

BOLT, SOCKET HD, 5/16-18 X 2 1/2

20

99003-015

1

WASHER, NYLON, 5/16 X 1/16

Sure-Feed

Engineering

Inc

14

1200EI-ECO SEPARATOR DEVICE ASSEMBLY CONT’ (fig. 6-2)

21

10009-011

1

ARM, SENSOR

22

10009-007

1

ARM, SENSOR

23

10009-008

1

ARM, SENSOR

24

10009-009

1

MOUNT, SENSOR

25

98009-001

1

SENSOR, RECIEVER

26

4

WASHER, LOCK #10

27

7

WASHER, FLAT, #10

28

2

NUT, LOCK, 10-24

29

1

SCREW, SKT HD, 10-24 X 3/4

30

2

SCREW, SKT HD, 6-32 X 1/2

31

3

SCREW, PAN HD, 10-24 X 1-1/4

Sure-Feed

Engineering

Inc

15

FIG. 6-2

Sure-Feed

Engineering

Inc

16

SIDE GUIDE ASSEMBLY (Fig. 6-3)

ITEM

PART NO.

QTY.

DESCRIPTION

1

10009-002

2

BRACKET, SIDE GUIDE MTG

2

10003-003

1

CROSS BAR, SE-1200-EI

3

10005-009

1

GUIDE, SIDE, RH (TALL)

4

10005-002

1

GUIDE, FRONT PAPER (TALL)

5

10005-008

1

GUIDE, SIDE, LH (TALL)

6

10005-014

1

GUIDE, BUSINESS, RH (TALL)

7

10007-008

2

BLOCK, BUSINESS GUIDE MTG

8

10005-015

1

GUIDE, BUSINESS, LH (TALL)

9

99004-002

6

KNOB, #10 SCREW

10

8

SCREW, SKT HD, 10-24 X 1/2

11

4

SCREW, BTN HD, 10-24 X 1/2

12

4

SCREW, FLAT HD, 10-24 X 3/8

13

8

SCREW, FLAT HD, 8-32 X 1/2

14

4

SCREW, FLAT HD, 6-32 X 1/2

15

10007-010

1

BLOCK, SEPARATOR ADJ

16

99004-003

2

HANDLE, RATCHET, 10-24

17

10007-007

2

BLOCK, BUSINESS GUIDE MTG (UPPER)

Sure-Feed

Engineering

Inc

17

FIG. 6-3

Sure-Feed

Engineering

Inc

18

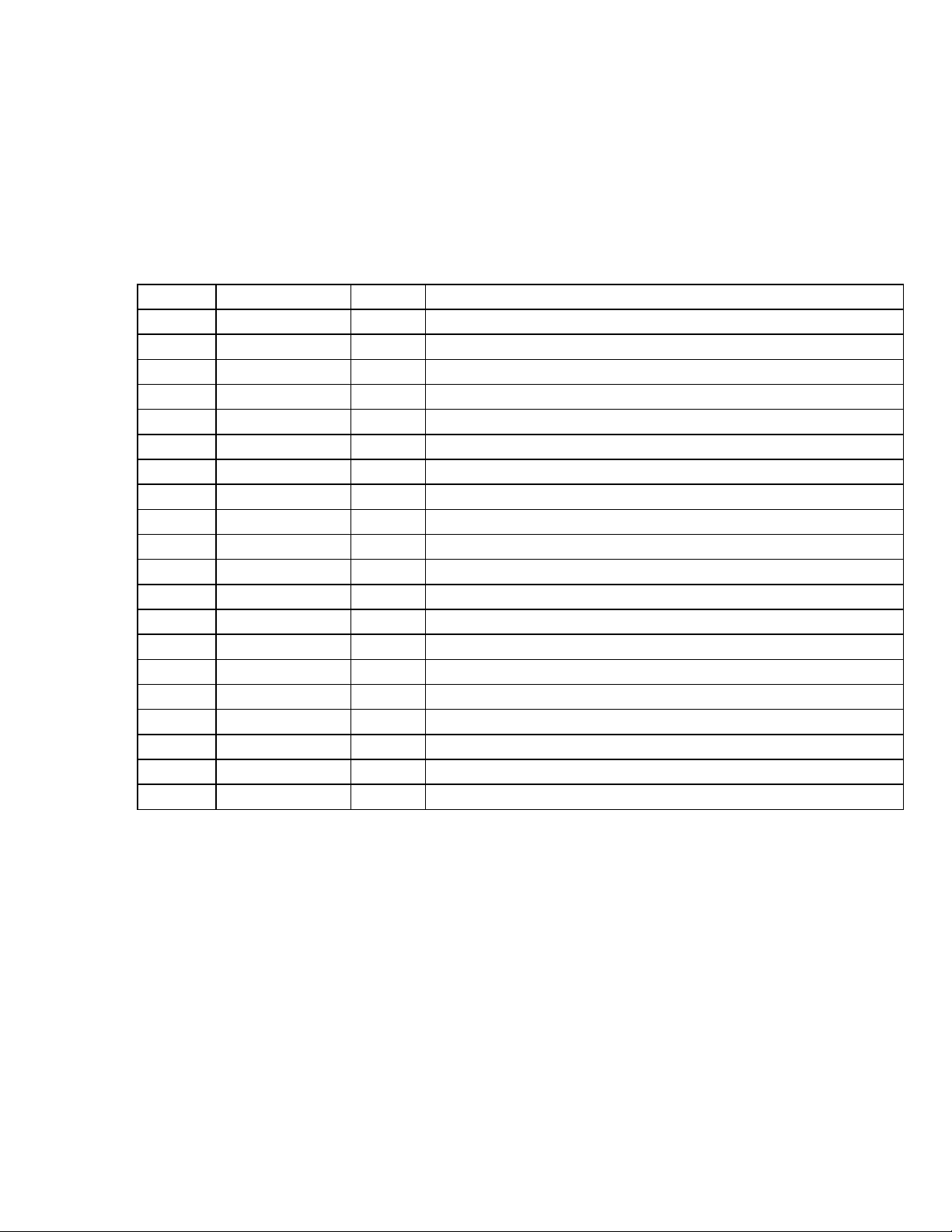

SHAFT ASSEMBLIES (Fig. 6-4)

ITEM

PART NO.

QTY.

DESCRIPTION

1

10004-009

1

SHAFT, FRONT, SE-1200-EI

2

10004-123

1

SHAFT, NIP ROLLER, 3/4 (1200 EI)

3

10004-045

1

SHAFT, MAIN, SE-1200-EI

4

10004-046

1

SHAFT, SUPPORT IDLER, SE-1200-EI

5

10006-070

2

NIP ROLLER, 3/4 BORE

6

10006-071

3

PULLEY, MATE, 3/4 BORE

7

10006-014

3

PULLEY, CROWNED

8

10006-007

2

FEEDER, ROLLER

9

10006-012

3

ROLLER, IDLER

10

99002-006

1

PULLEY, 24XL037

11

99002-003

2

PULLEY, 20XL037

12

99000-005

3

BELT, RED GUM

13

99000-001

1

BELT, TIMING, 90XL037

14

99003-083

4

BEARING, 1/2 X 1-1/8, SHIELDED W/ S.R.

15

99003-001

6

BEARING, SHIELDED, 3/8 X 7/8

16

99022-004

2

SNAP RING, 1/2

17

99003-018

5

WASHER, NYLON, 1/2 X 1/16

18

99022-003

6

SNAP RING, 3/8

19

99003-056

2

BEARING, SEALED, 1/4 X 5/8

20

16

SET SCREW, 10-24 X 3/8

21

6

SET SCREW, 8-32 X 3/8

22

2

SCREW, FLAT HD, 8-32 X 1/2

23

10006-069

2

FEEDER ROLLER, 3/4 BORE

24

10006-021

2

PULLEY, DRIVE, 22XL875

Sure-Feed

Engineering

Inc

19

FIG. 6-4

This manual suits for next models

1

Other Sure-Feed Engineering Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

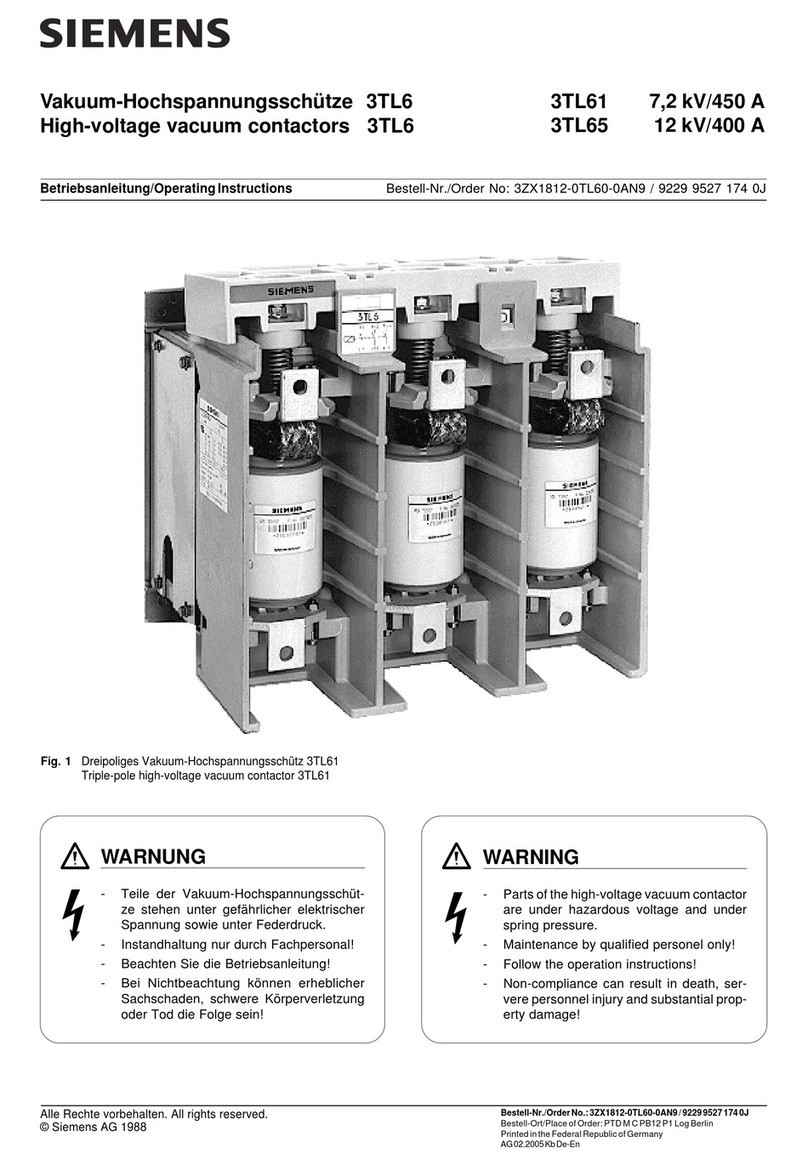

Siemens

Siemens 3TL61 operating instructions

Hammerhead

Hammerhead 100XTR Operator's manual

SAMCHULLY

SAMCHULLY PHD instruction manual

FläktGroup

FläktGroup ECONET Installation & maintenance manual

6K Products

6K Products DH0606 Operation and parts manual

Schrempp electronic

Schrempp electronic MG-3-T4-TRIO IOL M8 manual