Surewerx Jackson WH70 BH3 User manual

I

WH70 BH3®

With Balder®Technology

ANSI Z87.1

Meets CSA/CAN Z94.3

Welding Helmet

Casque de soudeur

Casco para soldar

User Instructions

Instructions d

’utilisation

Instrucciones de uso

II

USA:

SureWerx USA Inc.,

Elgin, IL, USA 60123

surewerx.com/usa

Canada:

SureWerx, 49 Schooner St.,

Coquitlam, BC V3K 0B3

surewerx.com

Europe:

Balder d.o.o. Teslova ulica 30,

SI-1000 Ljubljana, Slovenia

balder.eu

1

TABLE OF CONTENTS

Warning and precautions ........................................................1

Overview ................................................................................ 2

Operating Instructions ............................................................ 2

WH70 BH3®Helmet and headgear assembly ........................ 3

WH70 BH3®Helmet and hard hat assembly .......................... 4

ADF welding lter and protection screens assembly......... 5 - 8

WARNING!

THIS HELMET PROVIDES LIMITED PROTECTION FROM MINOR AND INCIDENTAL IMPACT HAZARDS, AND NO PROTECTION WHILE IN

THE RAISED POSITION. DO NOT RELY ON THIS WELDING HELMET AS YOUR PRIMARY PROTECTION FROM IMPACT OR SPLASH HAZ-

ARDS. FOR YOUR PROTECTION, READ THESE WELDING HELMETAND ADF INSTRUCTIONS COMPLETELY BEFORE USING. FAILURE

TO FOLLOW ALL OF THESE INSTRUCTIONS CAN RESULT IN SERIOUS AND PERMANENT INJURY, VISION LOSS OR BURNS.

IMPACT RESISTANT SAFETY SPECTACLES

OR GOGGLES MUST BE WORN AT ALL TIMES

WHEN USING THIS HELMET.

Clear polycarbonate protective plates must be installed on both

the inside and outside of the auto-darkening filter (ADF) before

use. Failure to use protective plates can result in irreparable

damage to the ADF and may cause serious and parmenent

injury, vision loss or burns. Damage to the lens from failure to

install clear plates will void the warranty. The protective cover

plates of this helmet only provide protection against splatters

and surface damage to the lens, NOT against severe impact

hazards, such as fragmented grinding wheels or abrasive discs,

explosive devices or corrosive liquids.

BEFORE WELDING

• Ensure that the helmet is correctly assembled and that it com-

pletely blocks any accidental light. In the front, light may enter

the helmet only through the viewing area of the autodarkening

welding filter.

• Adjust the headgear to ensure maximum comfort and to

provide the largest field of vision.

• Select a suitable welding filter for the shield. Dimensions of

the filter: 110x110mm.

• Check the prescribed shade level for your welding application

and adjust your autodarkening filter accordingly (see the table

with recommended shade levels).

PRECAUTIONS

• Never place the helmet or the autodarkening welding filter on

hot surface.

• Scratched or damaged protection screens should be regularly

replaced by original JACKSON SAFETY

®

replacement parts.

Before using the new protection screen, make sure to remove

any additional protection foil from both sides.

• Only use the WH70 BH3

®

within the temperature range of

-23°F to +131°F (-5°C to +55°C).

• Never expose the autodarkening welding filter to liquids and

always protect it from dirt.

• Only use original JACKSON SAFETY

®

spare parts. In case of

doubt, please contact your JACSKON SAFETY

®

authorized

dealer.

• Failure to follow these instructions will invalidate the warranty.

Surewerx does not accept responsibility for any problems

which may arise from applications other than welding, or if the

instructions for use are not strictly followed. The WH70 BH3

®

welding helmet is manufactured to protect the welder’s face

against spatters and hazardous ultraviolet and infrared rays

emitted during the welding process. It is not intended to be

used as a protection against impact, flying particles, molten

metals, corrosive liquids or hazardous gases.

• Do not use for overhead welding where there is a falling

molten metal hazard. This welding helmet/filter system does

not provide protection from molten metal and spatter during

direct overhead welding.

• Materials which may come into contact with the wearer’s skin

could cause allergic reactions to susceptible individuals.

• Any welding helmet worn over standard ophthalmic spectacles

may transmit impact, thus create a hazard to the wearer.

• If the helmet and the protection screen both do not carry the B

marking, then only the S marking is valid.

• If protection against high speed particles at extreme tem-

peratures is required then selected eye-protector should be

marked with the letter T immediately after the impact letter.

If the impact letter is not followed by the letter T then eye

protector shall only be used against high speed particles at

room temperature.

• A distance of at least 50cm, and never less than 25cm, be-

tween the welding arc and the welder eyes is recommended

for all welding applications.

Shade levels for various welding applications ....................... 9

Light transmission curve ........................................................ 9

Description of JACKSON SAFETY® lter features ........ 10 - 11

Technical data ...................................................................... 12

Markings .............................................................................. 13

Original spare parts ...................................................... 14 - 15

Warranty and certection...................................................... 16

2

AUTODARKENING WELDING PROTECTION

FILTER

OPERATION

JACKSON SAFETY

®

autodarkening welding protection filters

operate on the basis of a liquid crystal light shutter that protects

the welder’s eyes against intense visible light emitted during

the welding process. In combination with the permanent pas-

sive IR/UV filter, it protects against hazardous infrared (IR) and

ultraviolet (UV) light. The protection against harmful radiation is

present regardless of the shade level or potential malfunction

of the filter, beyond the darkest shade number marked on each

specific model.

JACKSON SAFETY

®

autodarkening welding protection filters

are manufactured according to EN 379 requirements and are

CE, DIN as well as DIN Plus certified. They are not intended

to be used as a protection against impacts, flying particles,

molten metals, corrosive liquids or hazardous gases. Replace

potentional malfunctioned (check that the autodarkening filter

turns dark if you strike the welding arc) or physically damaged

autodarkening welding filter.

Protection screens, both internal and external

(polycarbonate or CR39), must be used in con-

junction with the autodarkening filter in order

to protect it against permanent damage.

USAGE

An autodarkening welding protection filter built into a welding

helmet is considered to be »Personal Protection Equipment«

(PPE) protecting the eyes, face, ears and neck against direct

and indirect hazardous light of the welding arc. In case that you

have only bought a filter without the helmet, you need to select

the appropriate helmet designed to be used in combination

with an autodarkening welding protection filter. It has to allow

the filter, including the internal and external protection screens,

to be adequately mounted into the helmet. There should be no

increased point tensions caused by the fixing frame or mount-

ing system, as they could cause severe damage to the filter.

Make sure that solar cells and photo-sensors are not covered

by any part of the helmet, as this could prevent the proper

operation of the filter. If any of these conditions occur, the filter

may not be suitable for use.

FIELD OF APPLICATION

JACKSON SAFETY

®

filters are suitable for all types of electro-

welding: covered electrodes, MIG/MAG, TIG/WIG, plasma

welding, cutting and laser welding (only selected models with

two shade ranges, i.e.6-8 and 9-13), except for gas welding.

FUNCTIONS

JACSKON SAFETY®filters are supplied ready

for use. Check the degree of required protec-

tion for specific welding procedure and if a

certain model allows you, select the recom-

mended shade, light sensitivity as well as

opening time delay.

Shade adjustment:

Some models (Grand DS, Grand ES)

enable shade adjustment range from 9 to 13. Grand GDS has

two shade ranges, i.e. 6-8 and 9-13. It can be adjusted by the

knob »Range« which is located on the filter. The external knob

for shade adjustment has two shade ranges (6-8 and 9-13)

marked in two different typefaces (positive and negative). The

adjustment of the knob »Range« defines the range which is

being used.

Adjustment of sensitivity:

Most welding applications

can be performed with welding light sensitivity set to maximum.

The maximum sensitivity level is appropriate for low welding

current work, TIG, or special applications. The welding light

sensitivity has to be reduced only in some specific surrounding

lighting conditions in order to avoid unwanted triggering. As a

simple rule for optimum performance, it is recommended to set

sensitivity to the maximum at the beginning and then gradually

reduce it, until the filter reacts only to the welding light flashes

and without annoying spurious triggering due to ambient light

conditions (direct sun, intensive artificial light, neighboring

welder’s arcs etc.).

Opening time delay adjustment: The opening time

delay can be adjusted from 0.1 to 1.0 seconds. It is recom-

mended to use a shorter delay with spot welding applications

and a longer delay with applications using higher currents and

longer welding intervals. Long er delay can also be used for

low current TIG welding in order to prevent the filter opening

when the light path to the sensors is temporarily obstructed by

a hand, torch, etc.

Function welding/grinding (model Grand GDS only):

For these filters, two modes of operation can be selected:

welding or grinding. By selecting the position »Grind«, the

filter switches off and it will not be triggered by the sparks

generated during grinding. Before restarting welding work,

the knob should be set back to the »Weld« position.

3

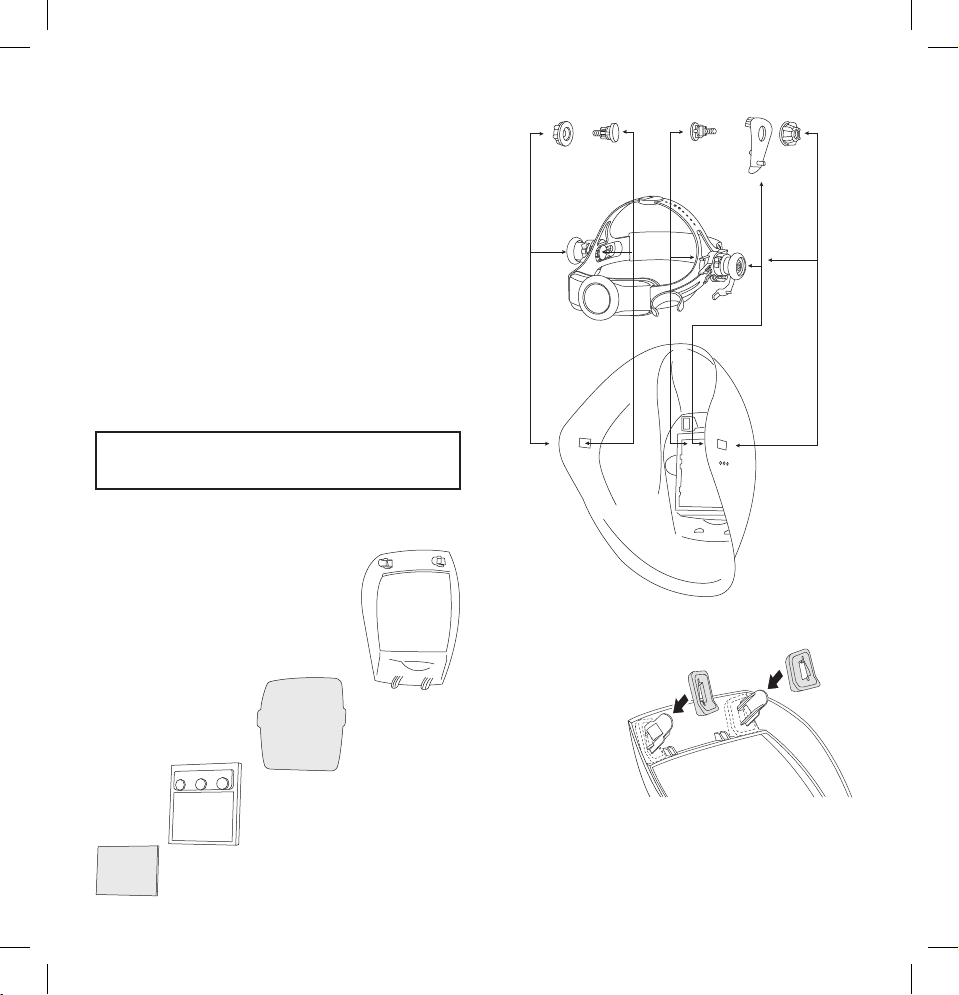

A A CC B

D

E

F

ZZ

WH70 BH3®HELMET AND HEADGEAR

ASSEMBLY

1. Insert screws (A) through the openings in the headgear (D).

2. Insert the headgear (D) into the helmet shell (F) as shown

in figure 1 and push the screws (A) through the rectangular

openings in the helmet shell.

3. Put the tilt adjustment (B) on the right side between the

screw (A) and helmet shell (F). Make sure that a small

pin is fixed in one of the three holes in the helmet shell.

Choose the right hole for your maximum comfort.

4. Tighten the nuts (C) on the screws (A). Before adequately

tightening them, place the headgear at the most comfort-

able distance from the filter opening by adjusting the

possition of headgear within the two rectangular holes in

the helmet shell.

5. The headgear size (D) can be adjusted by turning the rear

wheel (E) in order to fit any head size. Press the wheel

and hold it while turning, release the wheel when reaching

the position of maximum comfort, so that it will lock in the

required position.

The headgear is equipped with a replace-

able sweatband. Sweatbands are available

through your local dealer.

WASHERS ASSEMBLY

In order to assure adequate sealing in the hood and meeting the

safety standards, the WH70 BH3

®

must be additionally equiped

with a pair of washers. The washers are (Z) attached into the

two upper inner pins of the external control frame.

This manual suits for next models

3

Table of contents

Languages:

Other Surewerx Welding Accessories manuals