05/26/16

670- 00018B

1

1.0 Table of Contents

2.0 Introduction........................................................................................................................2

3.0 Safety Instructions.............................................................................................................2

4.0 How it Works .....................................................................................................................5

4.1 Extension Cycle................................................................................................................5

4.2 Retraction Cycle:..............................................................................................................6

5.0 Unpacking Instructions.....................................................................................................6

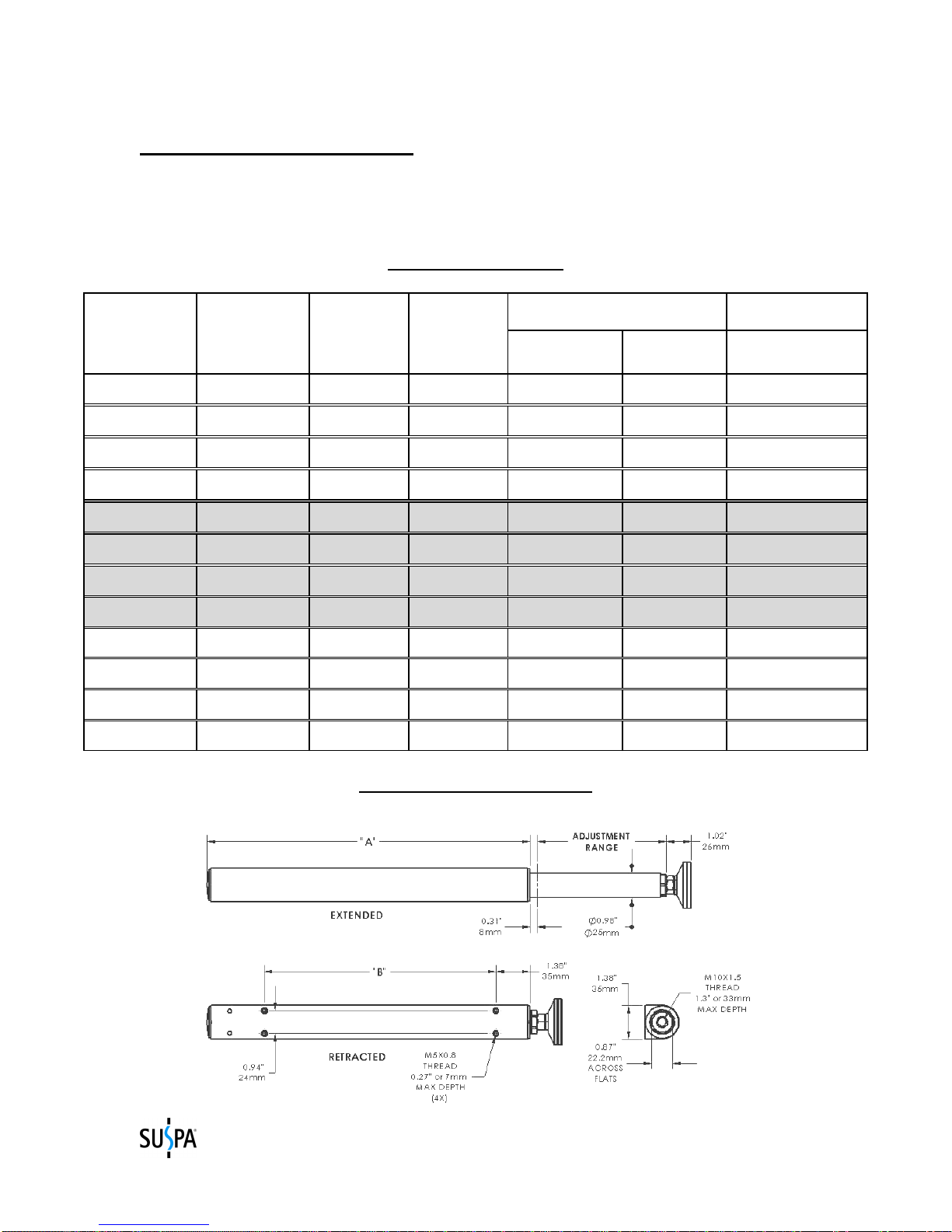

6.0 Lift System Specifications.................................................................................................8

6.1 Lift Cylinder Specifications.............................................................................................8

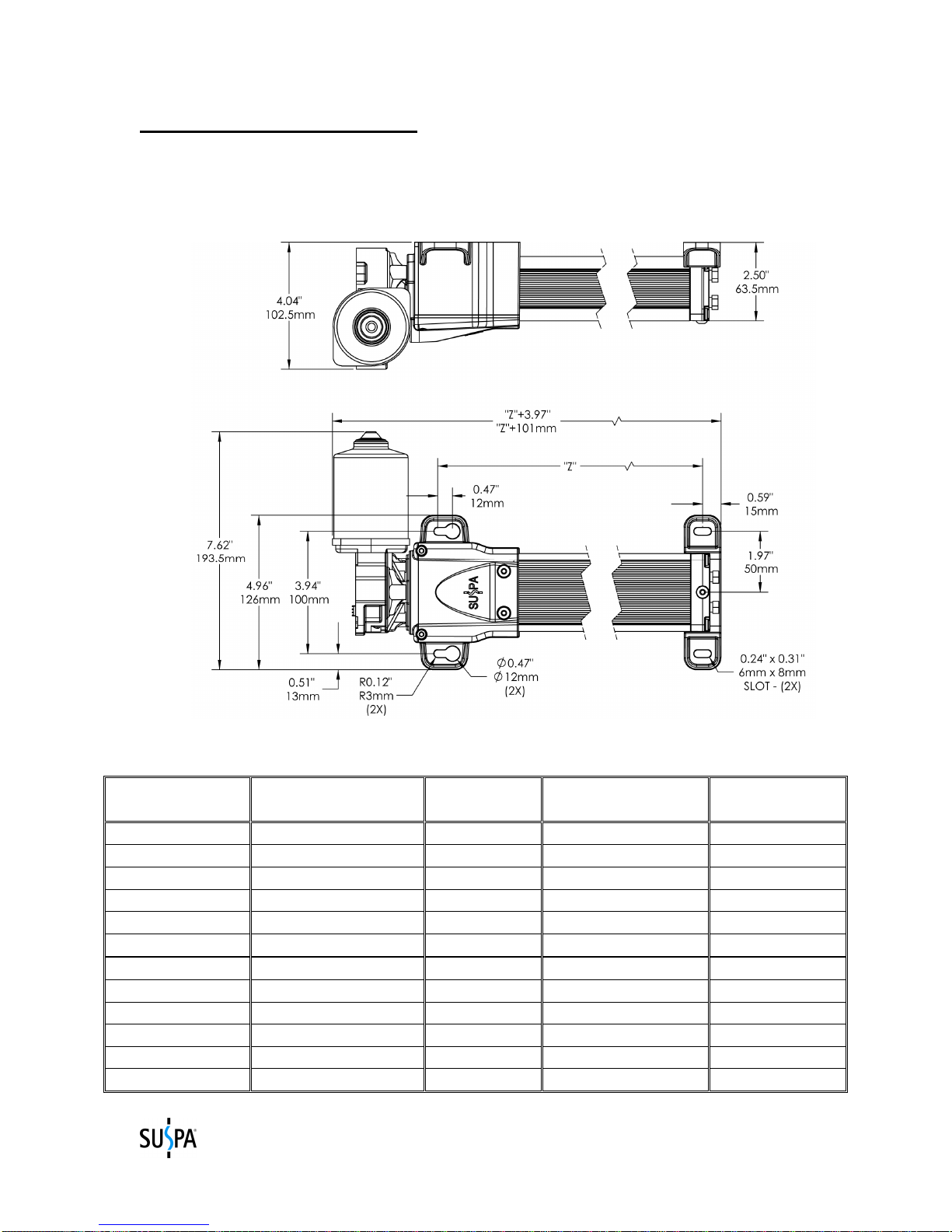

6.2 Motorized Pump Specifications.......................................................................................9

6.3 Motor Controller Specifications.....................................................................................10

6.4 Surface Mount Switch Specifications ............................................................................11

6.5 Regulatory Information..................................................................................................11

7.0 Installation Instructions..................................................................................................12

7.1 System Component Placement.......................................................................................12

7.2 Motorized Pump Installation..........................................................................................13

7.3 Motor Controller Installation .........................................................................................14

7.4 Low Profile Switch Installation......................................................................................15

7.5 Controller Cable Connections........................................................................................16

7.6 Lift Cylinder Installation................................................................................................17

7.7 Hydraulic Tubing and Cable Management ....................................................................20

7.8 Workstation Leveling.....................................................................................................20

8.0 Operation Instructions....................................................................................................22

8.1 Before Connecting to Power ..........................................................................................22

8.2 Connecting to Power......................................................................................................23

8.3 First Operation................................................................................................................23

8.4 System Extension Cycle.................................................................................................25

8.5 System Retraction Cycle................................................................................................25

8.6 Duty Cycle Monitoring ..................................................................................................26

8.7 Deceleration Zone..........................................................................................................26

8.8 System Reset Procedure.................................................................................................26

8.9 Limit Alteration Instructions..........................................................................................27

9.0 Troubleshooting...............................................................................................................28

10.0 Inspection and Maintenance.........................................................................................29

10.1 Changing Load Conditions...........................................................................................29

10.2 Motor and Load Alignment..........................................................................................29

10.3 Contamination..............................................................................................................29

10.4 Power Cord and Hydraulic Tubing Damage................................................................29

11.0 Warranty........................................................................................................................30

12.0 Replacement Parts.........................................................................................................31

13.0 Optional Accessories and Enhanced Capabilities.......................................................31

14.0 Disposal...........................................................................................................................31

15.0 Contact Information......................................................................................................31