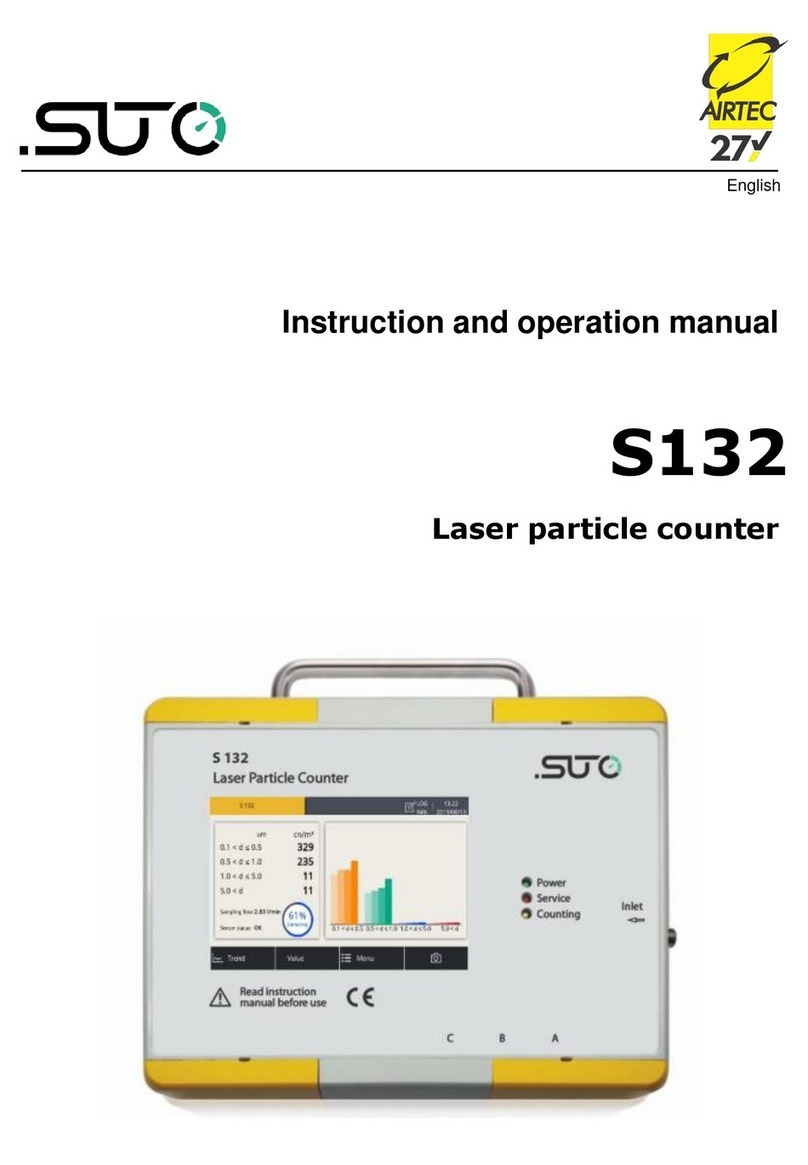

SUTO S132 Manual

English

Instruction and Operation Manual

S132

Laser Particle Counter

Dear Customer,

Thank you for choosing our product.

Before you start up the device please read this manual in full and

carefully observe instructions stated in this manual. The manufacturer

cannot be held liable for any damage that occurs as a result of non-

observance or non-compliance with this manual.

Should the device be tampered with in any manner other than a

procedure that is described and specified in the manual, the warranty is

void and the manufacturer is e empt from liability.

The device is destined e clusively for the described application.

SUTO offers no guarantee for the suitability for any other purpose.

SUTO is also not liable for consequential damage resulting from the

delivery, capability or use of this device.

2 S132

Table of Contents

1 Safety instructions......................................................................4

2 Registered trademarks.................................................................6

3 Application.................................................................................7

4 Features....................................................................................7

5 Technical data.............................................................................8

5.1 General data.........................................................................8

5.2 Electrical data.......................................................................8

5.3 Output signals......................................................................9

5.4 Counting efficiency................................................................9

5.5 Procedure of general particle counting .....................................9

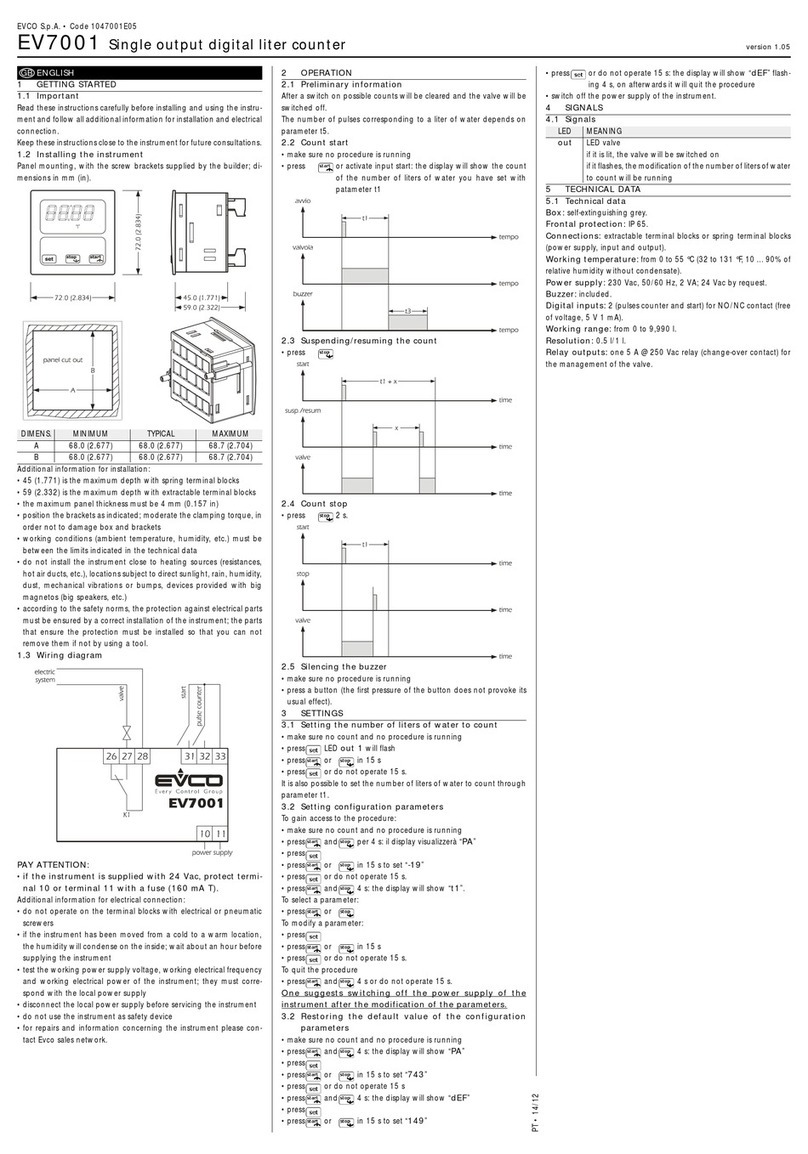

6 Dimensional drawing..................................................................10

7 Installation ..............................................................................11

7.1 Installation methods............................................................11

7.2 Installation procedure .........................................................13

7.3 Electrical connection............................................................15

8 Configuration ...........................................................................17

8.1 Integrated display...............................................................17

8.2 Service kit..........................................................................17

8.3 E ternal display ..................................................................17

9 Operation using the integrated display.........................................18

9.1 Value view..........................................................................18

9.2 Icons in the status bar.........................................................19

9.3 Trend view..........................................................................20

9.4 Menu.................................................................................21

9.5 Sensor settings...................................................................22

9.5.1 Analog output...............................................................22

9.5.2 Counter setting.............................................................23

9.5.3 Alarm settings...............................................................24

9.5.4 Modbus settings............................................................25

9.5.5 Sensor Info...................................................................25

10 LED indicators at the front panel................................................26

11 Signal outputs.........................................................................27

11.1 Analog output ..................................................................27

11.2 Modbus InterfaceDigital output............................................27

11.3 Alarm output ....................................................................29

12 Optional accessories................................................................30

13 Calibration..............................................................................31

14 Maintenance...........................................................................31

15 Disposal or waste....................................................................31

S132 3

1 Safety instructions

1 Safety instructions

Please check if this instruction manual matches the

product type.

Please observe all notes and instructions indicated in this

manual. This manual contains essential information that must

be observed before and during installation, operation and

maintenance. Therefore this manual must be read carefully by the

technician as well as by the responsible user or qualified personnel.

This instruction manual must be available at the operation site of the

product at any time. In case of any obscurities or questions regarding

this manual or the product, please contact the manufacturer.

WA NING!

Compressed air!

Any contact with quickly escaping air or bursting

parts of the compressed air system can lead to

serious injuries or even death!

•Do not e ceed the ma imum permitted pressure range (see

sensors label).

•Use only pressure-tight installation material.

•Prevent persons from being hit by escaping air or bursting parts of

the instrument.

•The system must be pressureless during maintenance work.

WA NING!

Voltage used for supply!

Any contact with energized parts of the device may

lead to an electrical shock which can lead to serious

injuries or even death!

•Consider all regulations for electrical installations.

•The system must be disconnected from any power supply during

maintenance.

•Any electrical work on system is allowed only by authorized

qualified personal.

4 S132

1 Safety instructions

ATTENTION!

Permitted operating parameters!

Observe the permitted operating parameters. Any

operation beyond these parameters can lead to

malfunctions and may lead to damage on the product

or the system.

•Do not e ceed the permitted operating parameters.

•Make sure that the product is operated under its permitted

conditions.

•Store and operate the product at the permitted temperature and

pressure.

•The product should be maintained and calibrated frequently, at

least annually.

General safety instructions

•It is not allowed to use the product in e plosive areas.

•Please observe the national regulations before and during

installation and operation.

emark

It is not allowed to disassemble the product.

ATTENTION!

Measurement values can be affected by malfunction!

The product must be installed properly and

maintained frequently. Otherwise it may lead to

wrong measurement values, which can lead to

wrong results.

Storage and transportation

•Make sure that the transportation temperature for the product

without display is between -30 ... +70°C and for the product with

display between -10 ... +60°C.

•It is recommended to use the packaging that comes with the

product for storage and transportation.

•Make sure that the storage temperature of the product is between

-10 ... +50°C.

S132 5

1 Safety instructions

•Avoid direct UV and solar radiation during storage.

•The storage humidity must be < 90% with no condensation.

ATTENTION!

Equipment may get damaged!

Please make sure, that your measuring point is free

of excessive contamination and dirt. This should

maintained before every measurement.

•Observe the measuring point always before measurement if it is

free of contamination like water drops, oil drops or other rough

contamination.

•Should water hit the inner electronics, the senors could be

seriously damaged.

•Before you start to measure, check your measurement point by

using a simple filter to see if any rough contamination is present.

(E ample of such a test device is shown below. Ask the supplier if

not sure.)

2 egistered trademarks

SUTO®Registered trademark of SUTO iTEC

MODBUS®Registered trademark of the Modbus Organization,

Hopkinton, USA

Android™,

Google Play

Trademarks of Google LLC

6 S132

3 Application

3 Application

The S132 is a laser particle counter, which is designed to measure

particles in compressed air or compressed gases. For the permissible

operating parameters, see chapter 5 Technical data.

The measurement result can be the number of particles per ft3 or m3.

You can choose the unit setting, as needed, using the optional

integrated display, an e ternal display, or the service kit.

The S132 laser particle counter is mainly used in compressed air

systems in industrial environments, and is not designed for use in

e plosive areas. To use it in e plosive areas, please contact the

manufacturer.

4 Features

•Measures particle content in compressed air or compressed gases.

•Easy connection through sampling hose and quick connector.

•Applicable to stationary or portable applications.

•Measures particles larger than 0.1 µm.

•Compliance with ISO 8573-4.

•Service indication through LED.

•Connectable to display and data logger produced by the

manufacturer and by third-party manufacturers.

•IP65 casing provides robust protection in rough industrial

environments.

•Optional integrated display for monitoring and configuration.

S132 7

5 Technical data

5 Technical data

5.1 General data

Parameters Particle counts per ft3 or m3

Principle of

measurement

Laser detection

Sensor LED-laser

Measured medium Compressed air

Measuring channels CH1: 0.1 < d ≤ 0.5 μm

CH2: 0.5 < d ≤ 1.0 μm

CH3: 1.0 < d ≤ 5.0 μm

CH4: 5.0 μm < d (configurable)

Flow rate 2.83 l/min

Sample rate 1 minute sampling time (Values are updated

every one minute.)

Ambient temperature +10 ... +40°C

Humidity of the

measured medium

< 90% rH, no condensation

Operating pressure 0.3 ... 1.5 MPa

Housing material PC, Al alloy

Protection class IP65

Dimensions See the dimensional drawing on page 10.

Display & data logger

(optional)

5” touch screen, 800 480 pi els

100 million values

Weight 3.2 kg

5.2 Electrical data

Power supply 24 VDC, 10 W without display

24 VDC, 20 W with display

8 S132

5 Technical data

5.3 Output signals

Analogue output 4 ... 20 mA

Digital output RS-485, Modbus/RTU

Alarm output NO, 40 VDC, 0.2 A

5.4 Counting efficiency

Counting efficiency

per ISO 21501-4

30 ... 70% of d > 0.1 µm

90 ... 110% of d ≥ 0.3 µm

5.5 Procedure of general particle counting

1. The S132 does not count any particles in the first 5 minutes.

During this period, it performs a purge process to ensure that any

remaining particles in the system are blown out.

2. After purging, the S132 starts sampling at a sampling interval of 1

minute.

a. In the ne t 40 minutes, S132 classifies the sampled values

based on particle sizes and then accumulates them.

b. After the 40 minutes, every one minute (sampling interval),

S132 removes the earliest sample values from the accumulated

values, and then add the latest sampled value into the

accumulated values to obtain the accumulated particle values

within the last 40 minutes.

S132 9

Other manuals for S132

1

Table of contents

Other SUTO Cash Counter manuals