SW-Stahl und Werkzeugvertriebs GmbH Tel. +49 (0) 2191 / 46438-0 www.swstahl.de

Leverkuser Straße 65 Fax +49 (0) 2191 / 46438-40

- 5 -

Do not store the machine and battery pack

in locations where the temperature may

reach or exceed 50oC (122oF).

Do not incinerate the battery pack even if it

is severely damaged or completely worn

out. The battery pack can explode in a fire.

Be careful not to drop, shake, or strike the

battery.

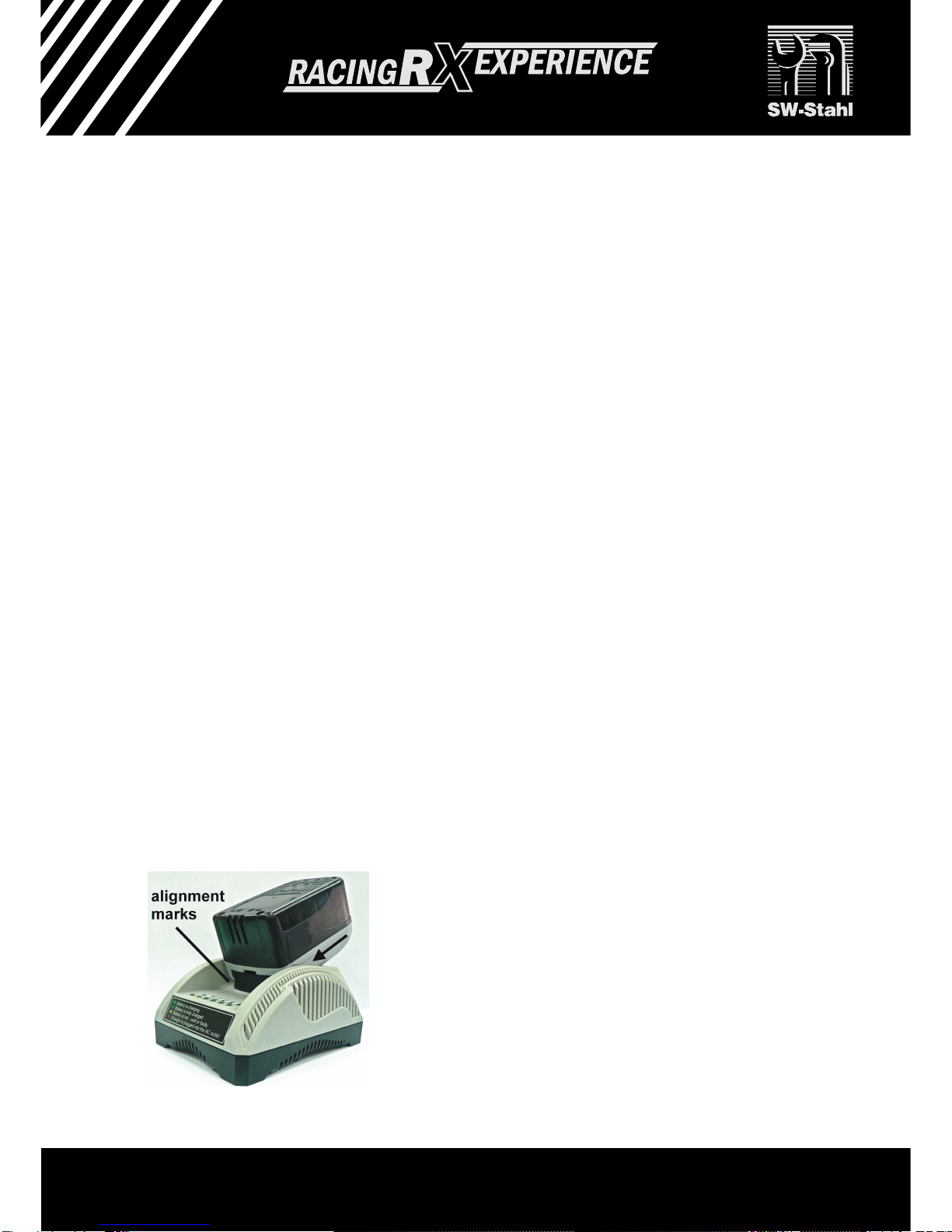

Do not charge inside a box or container of

any kind. The battery must be placed in a

well ventilated are during charging.

Do not dispose of battery packs into

household waste, fire or water. Battery

packs should be collected, recycled or

disposed of in an environmentally-friendly

manner. Call the authorized warranty

centers for places to dispose of damaged or

inoperable batteries.

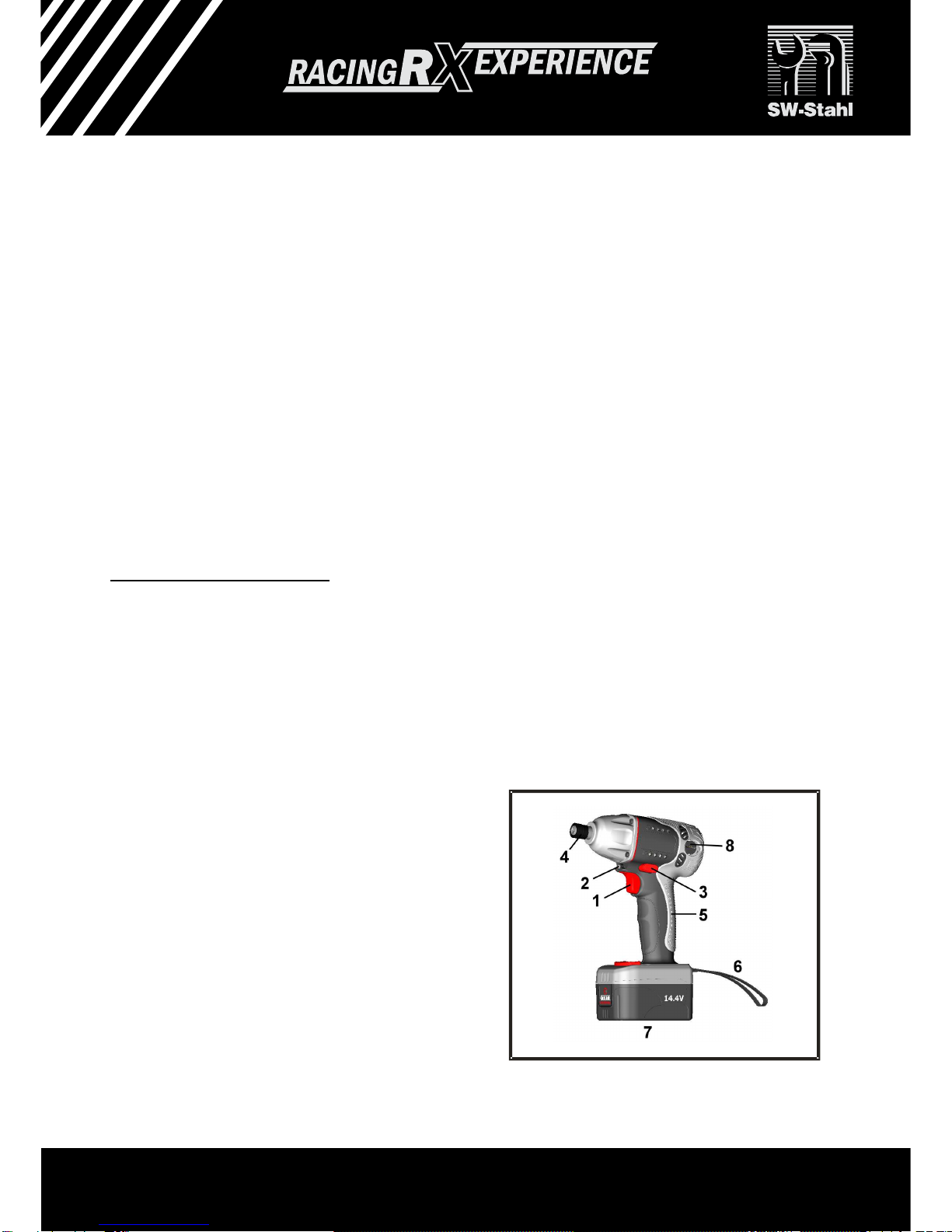

This impact driver is designed for wood/mild

steel drilling and screw driving. Please refer

to the figure on this page to familiarize

yourself with the major components of this tool

before use.

1. Power Switch

Depressing the power switch partially will

energize the LED light (2) in front. Pulling

further back will start the rotation action.

When released, power to the motor will

cease and drill chuck will stop to rotate. A

small amount of sparks may appear next to

the motor. This is normal as energy is

being converted to heat for dissipation.

3. Rotation Direction Switch

Pushing this switch to the left will cause the

chuck to spin in a “forward” direction, and

“reverse” when pushed to the right.

NOTE: In the center position, this switch will

lock out the power switch.

4. Quick Change Holder

This driver accepts only 6.35mm (1/4”)

hexagonal bits. Be sure the bit is fully engaged

by the chuck before operating tool. Otherwise,

the bit may fly off and cause property damage

or personal injury.

5. Non-slip Handle

The “rubberized” part of the handle gives a

more comfortable grip during operation,

shields operator from motor heat buildup, and

helps in reducing vibration and fatigue.

6. Lanyard (Shown in Fiqure1)

The lanyard is provided to help minimize the

occurrence of tool being dropped. Please use

it to your advantage and do not remove.

7. Li-ion/Ni-MH Battery

This battery provides electrical power to the

motor. Please charge it according to the

charging instruction listed in this manual.

8. Easy Brush Access Cover

The cover allows the user to access the

carbon brush for replacement.

Figure 1