Swagelok KCB Series Technical specifications

Other Swagelok Controllers manuals

Swagelok

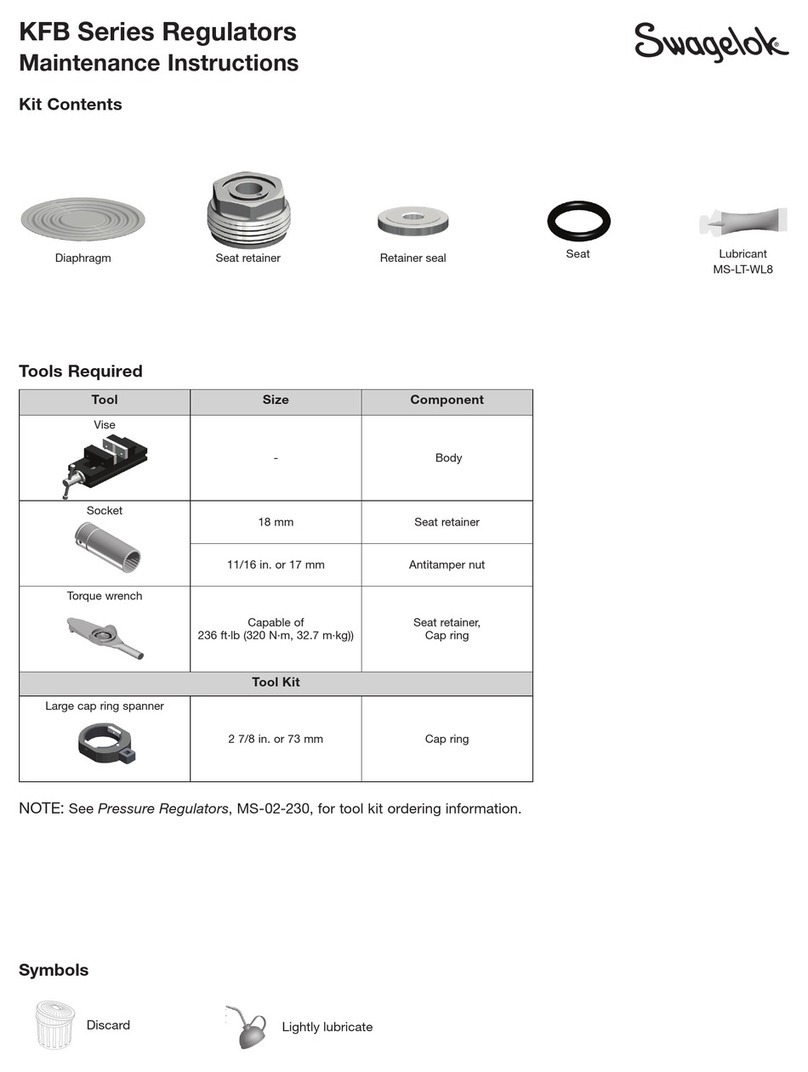

Swagelok KFB Series Technical specifications

Swagelok

Swagelok LBS4 User manual

Swagelok

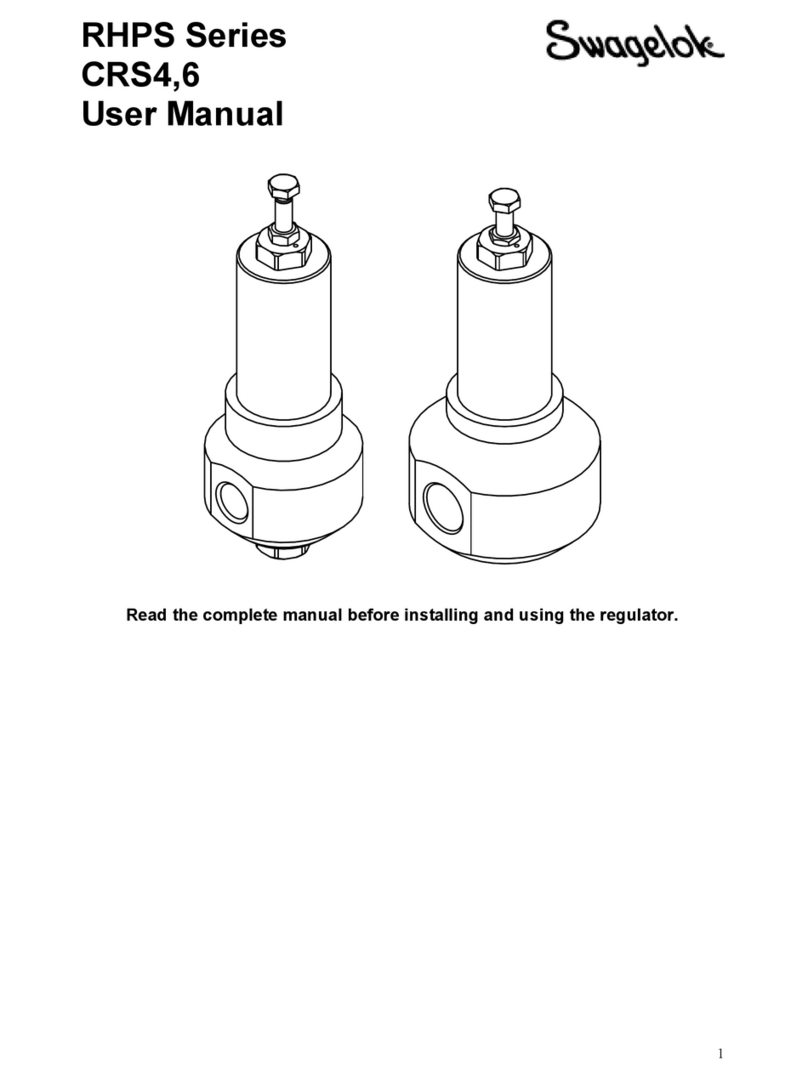

Swagelok RHPS Series User manual

Swagelok

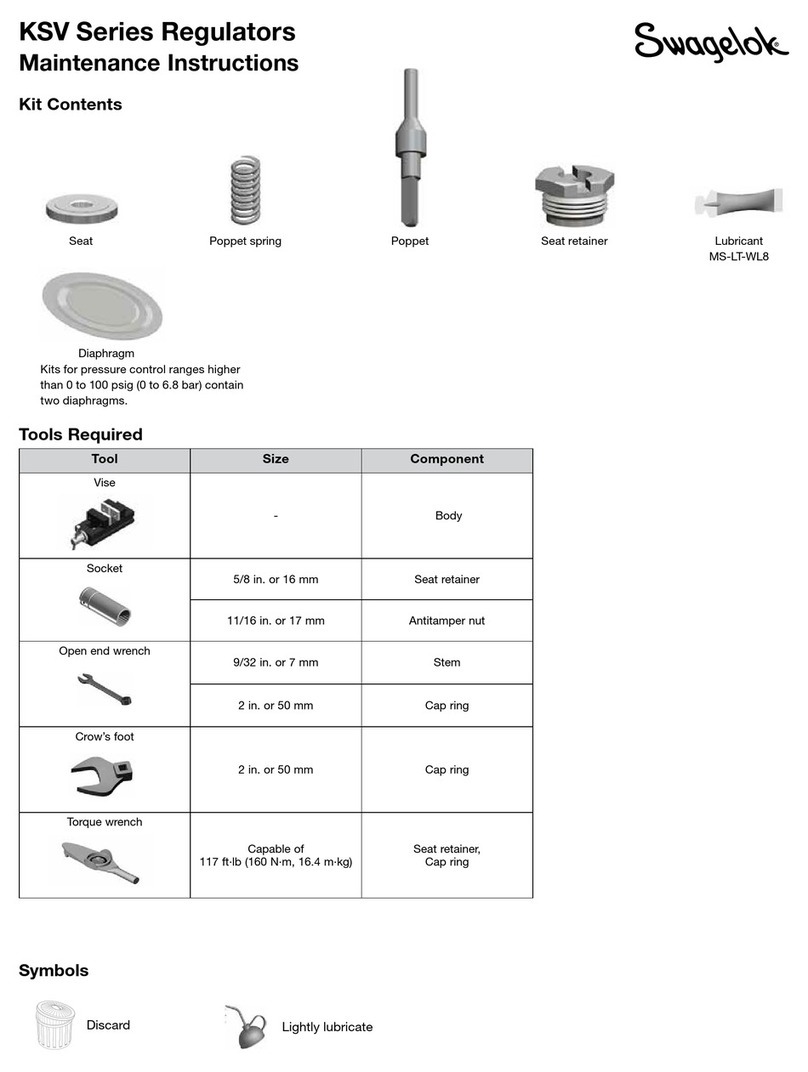

Swagelok KSV Series Technical specifications

Swagelok

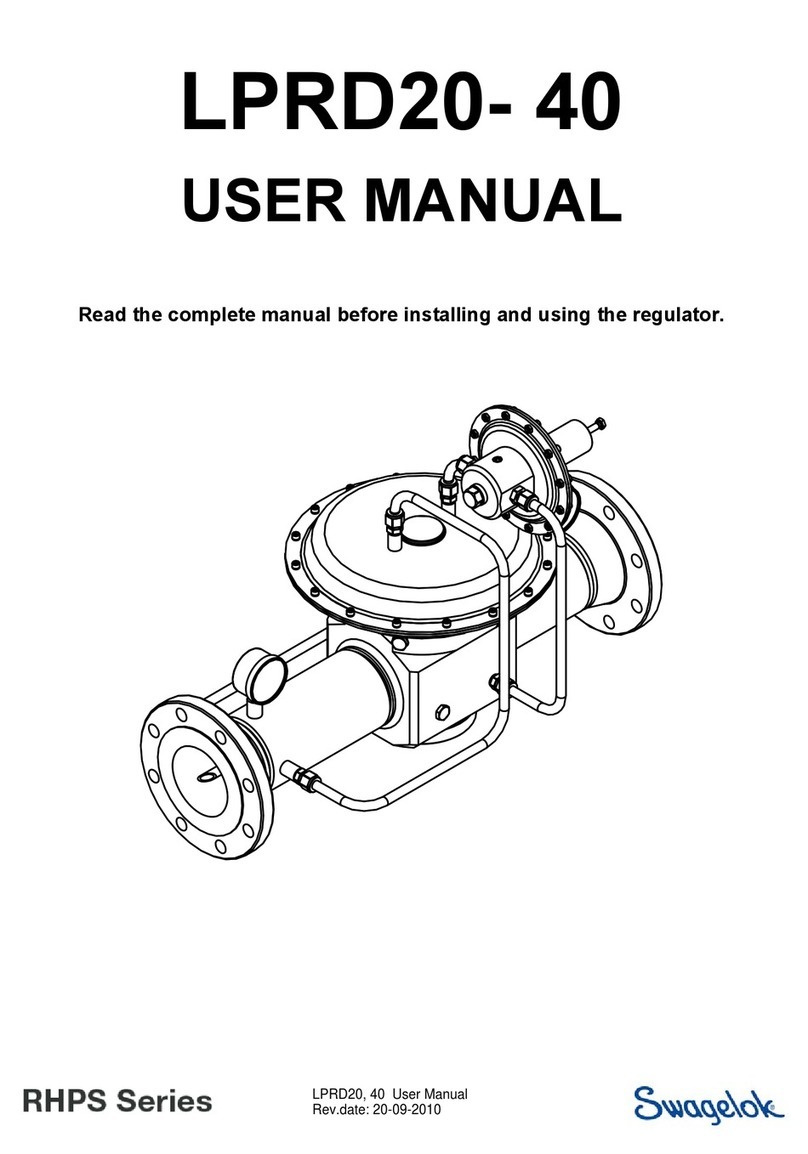

Swagelok RHPS Series User manual

Swagelok

Swagelok RHPS Series User manual

Swagelok

Swagelok RHPS Series User manual

Swagelok

Swagelok TBVS8 User manual

Swagelok

Swagelok RHPS Series User manual

Swagelok

Swagelok KCP Series Technical specifications

Swagelok

Swagelok RHPS Series User manual

Swagelok

Swagelok PRS15 User manual

Swagelok

Swagelok RS20 User manual

Swagelok

Swagelok BS20 User manual

Swagelok

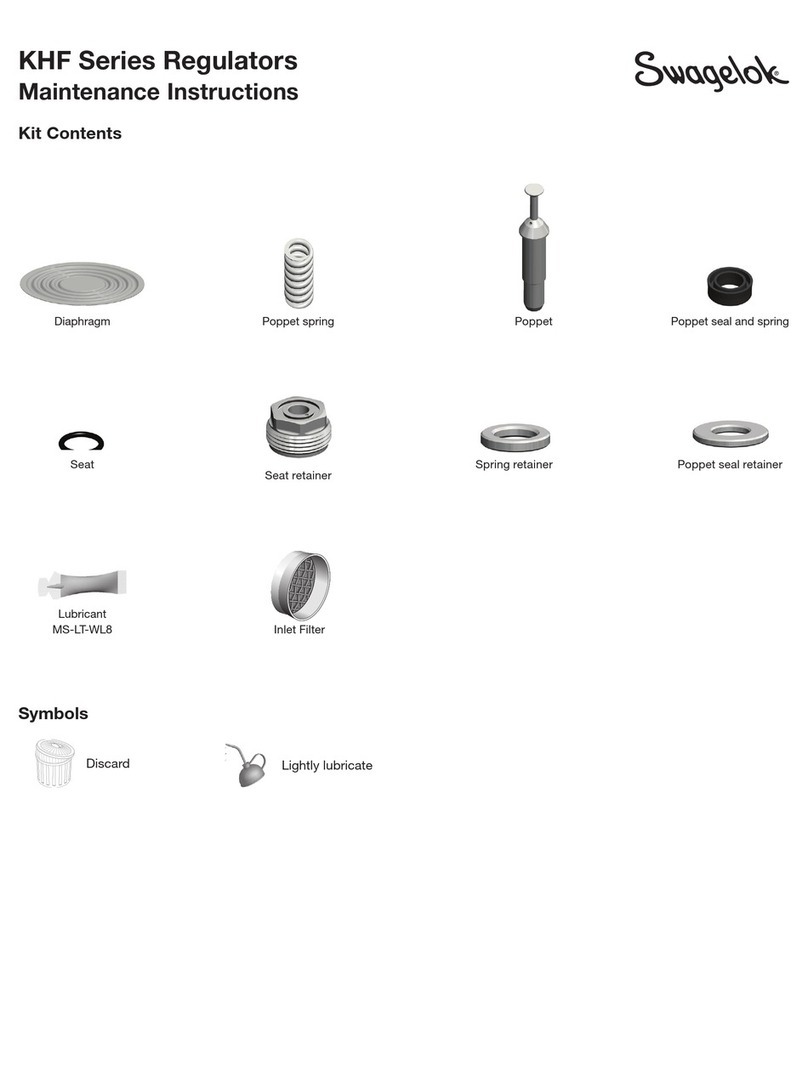

Swagelok KHF Series Technical specifications

Swagelok

Swagelok KHP Series Technical specifications

Swagelok

Swagelok KPR Series Technical specifications

Swagelok

Swagelok RA Series User manual

Swagelok

Swagelok BSH 10 Series User manual

Swagelok

Swagelok RHPS Series User manual