Content Page 3/40

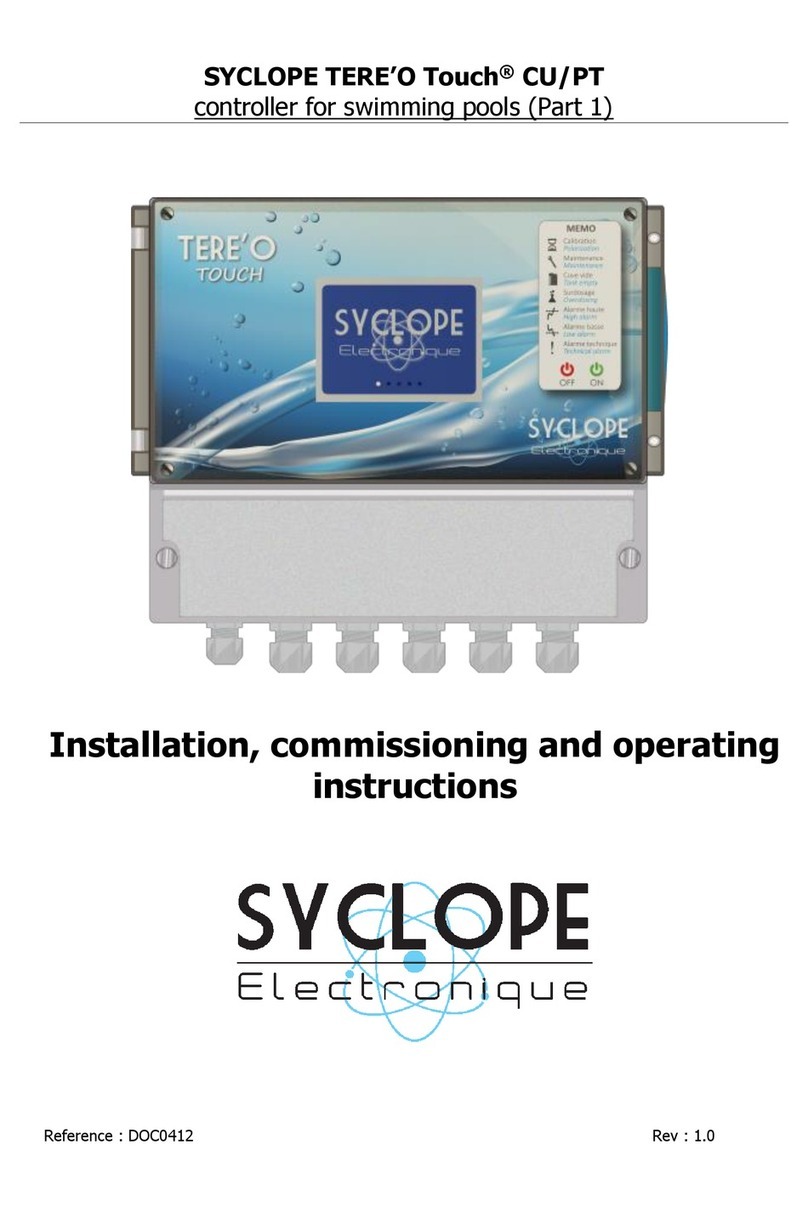

Installation, commissioning and operating instructions SYCLOPE TERE’O®

Content

I. Généralités................................................................................................................................4

1) Field application ....................................................................................................................4

2) FCC conformity .....................................................................................................................5

3) Utilisation du document .........................................................................................................6

4) Signs and safety symbols.......................................................................................................6

5) Storage and transport............................................................................................................7

6) Packaging .............................................................................................................................7

7) Warranty ..............................................................................................................................7

II. Environment and safety procedures........................................................................................8

1) Use of the equipment ............................................................................................................8

2) User obligations ....................................................................................................................8

3) Risk prevention .....................................................................................................................8

4) Identification and localization of the identification plate ...........................................................9

5) Disposal and conformity....................................................................................................... 10

III. Technical characteristics and functions .................................................................................11

1) Technical characteristics ......................................................................................................11

2) Main functions..................................................................................................................... 12

3) Parameter and scale of measurements .................................................................................12

IV. Installation and wiring .........................................................................................................13

1) Installation conditions.......................................................................................................... 13

2) Installation of the wall-mounted controllers...........................................................................13

3) Opening/Closing the transparent door ................................................................................. 14

4) Opening/Closing connection cover ........................................................................................ 14

5) Electrical connections .......................................................................................................... 15

6) Changing internal fuses of P1 and P2 outputs .......................................................................15

7) Connecting primary power supply.........................................................................................16

8) Connecting the self-powered relay P1................................................................................... 17

9) Connecting the measurement inputs.....................................................................................18

10) Connecting the voltage reference REF .............................................................................. 20

11) Wiring the external control entry (E4) ...............................................................................20

12) Connecting the RS485 communication port ....................................................................... 21

V. General use ........................................................................................................................23

1) Measurements come from gravity return line ........................................................................ 23

2) Measurements come from recirculating line ..........................................................................23

VI. Commissioning....................................................................................................................25

VII. Programming the controller.................................................................................................. 25

1) Keypad and LCD display ...................................................................................................... 25

2) « Factory » setting values ....................................................................................................27

3) Principle of programing........................................................................................................ 27

4) Polarisation of sensor ..........................................................................................................34

5) Calibration of the sensors .................................................................................................... 34

VIII. Entretien / Maintenance....................................................................................................... 36