Swagelok KLF Series User manual

Other Swagelok Controllers manuals

Swagelok

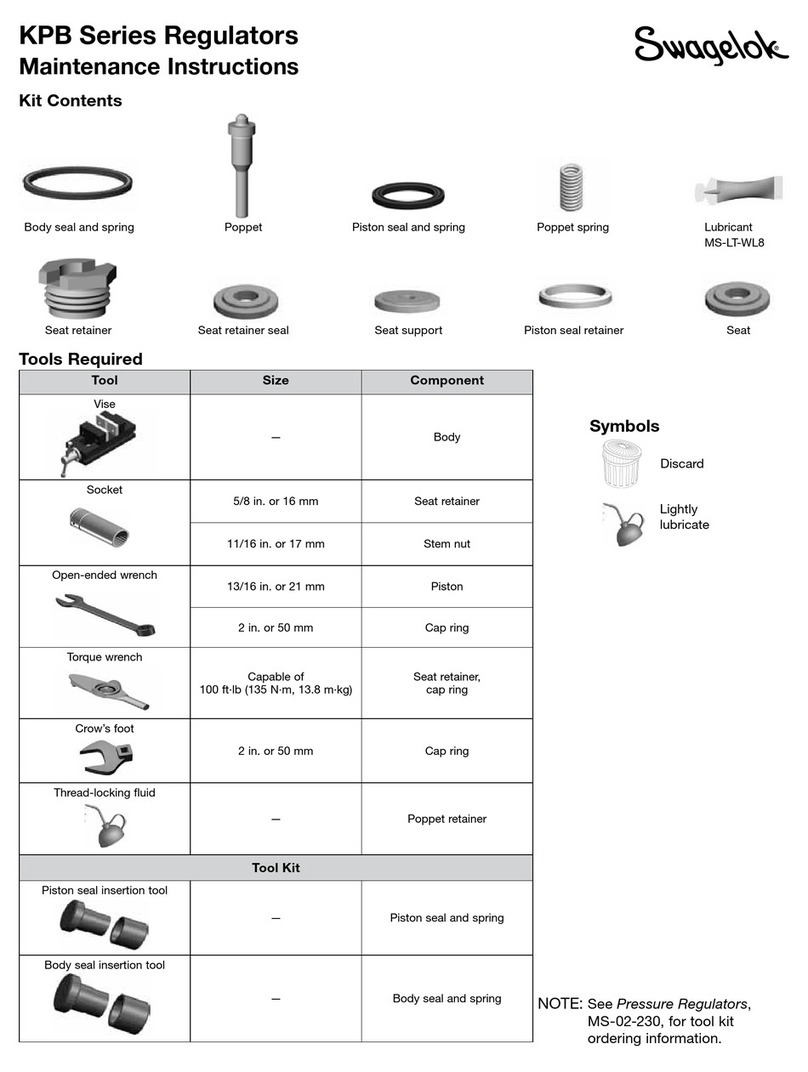

Swagelok KPB Series Technical specifications

Swagelok

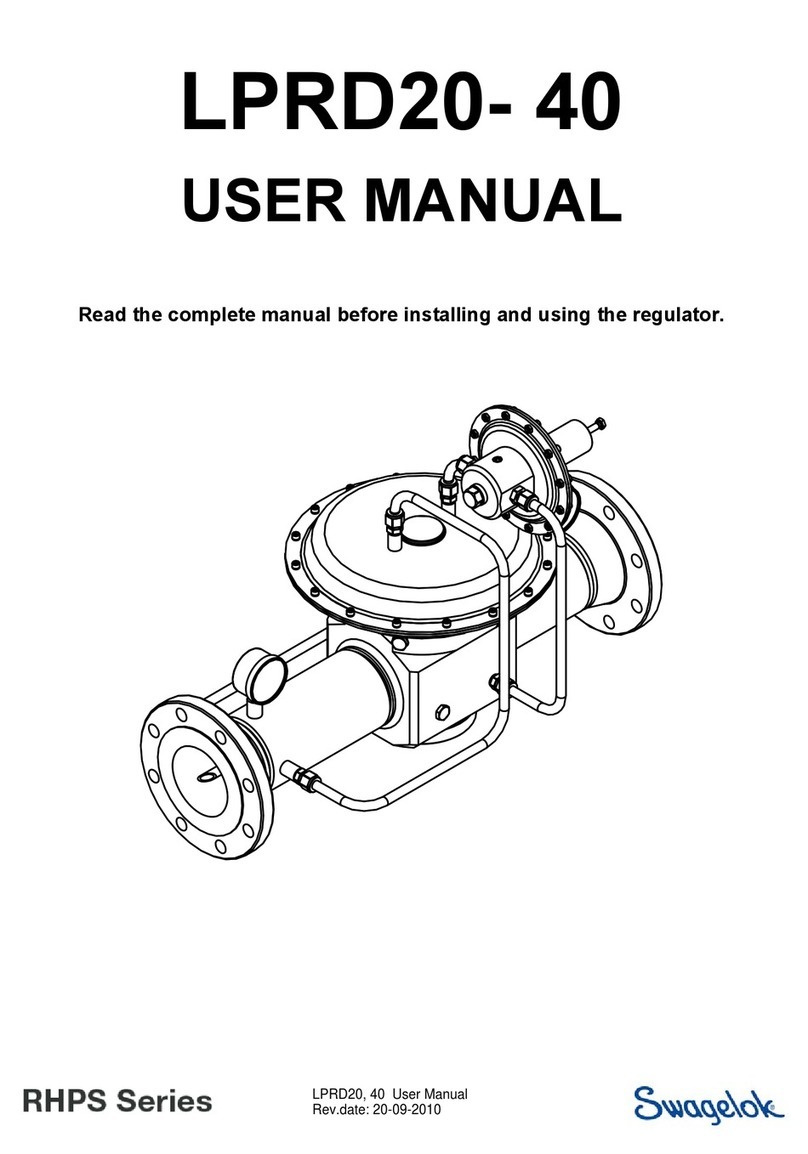

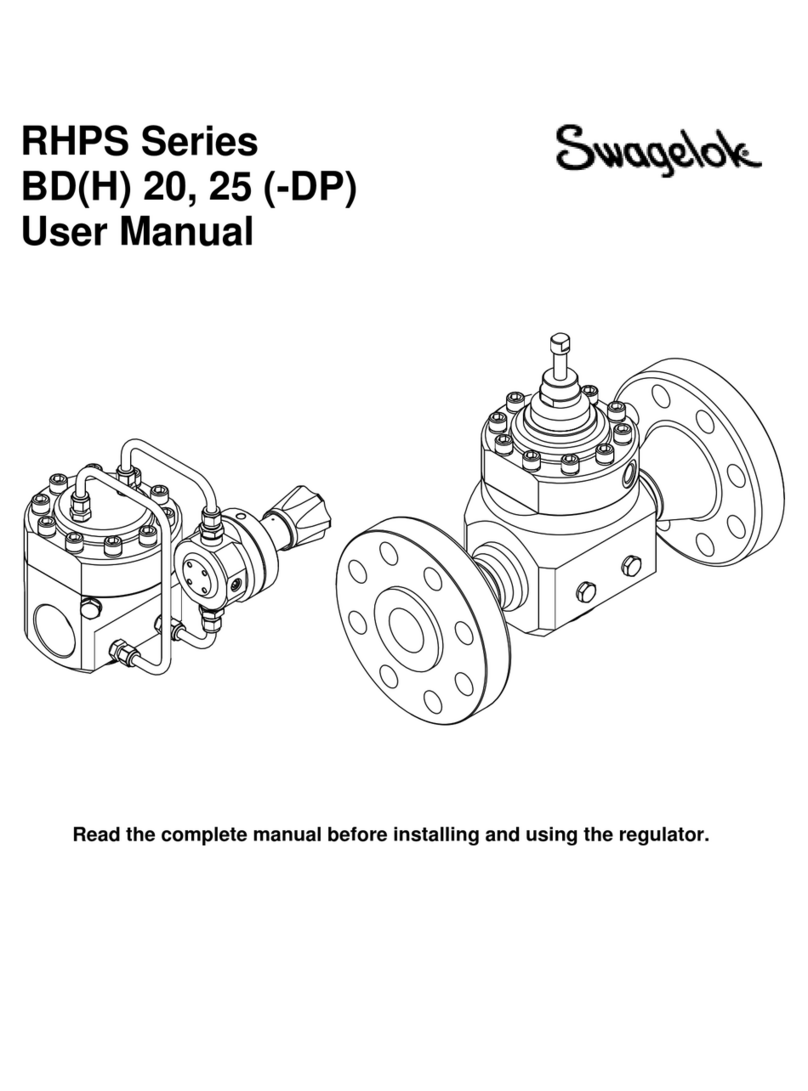

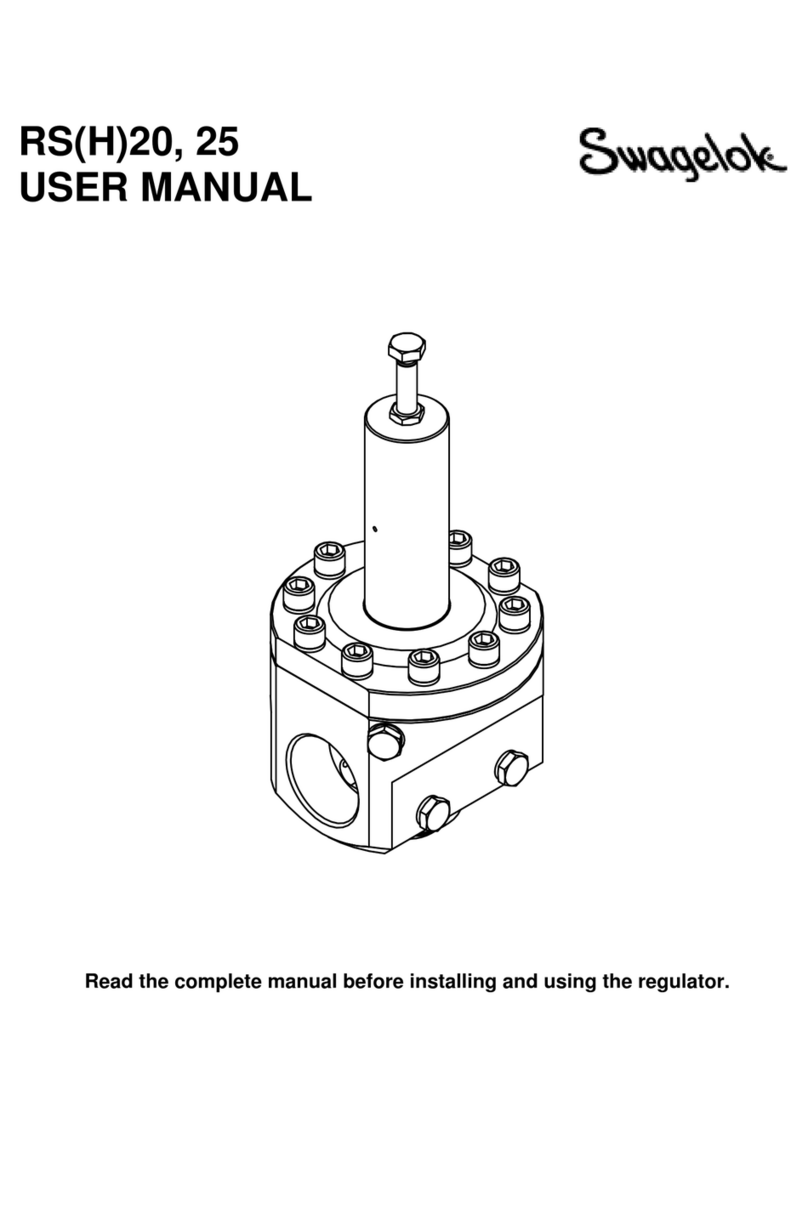

Swagelok RHPS Series User manual

Swagelok

Swagelok RHPS Series User manual

Swagelok

Swagelok KHP Series Technical specifications

Swagelok

Swagelok RS20 User manual

Swagelok

Swagelok RHPS Series User manual

Swagelok

Swagelok RHPS Series User manual

Swagelok

Swagelok KPR Series Technical specifications

Swagelok

Swagelok RHPS Series User manual

Swagelok

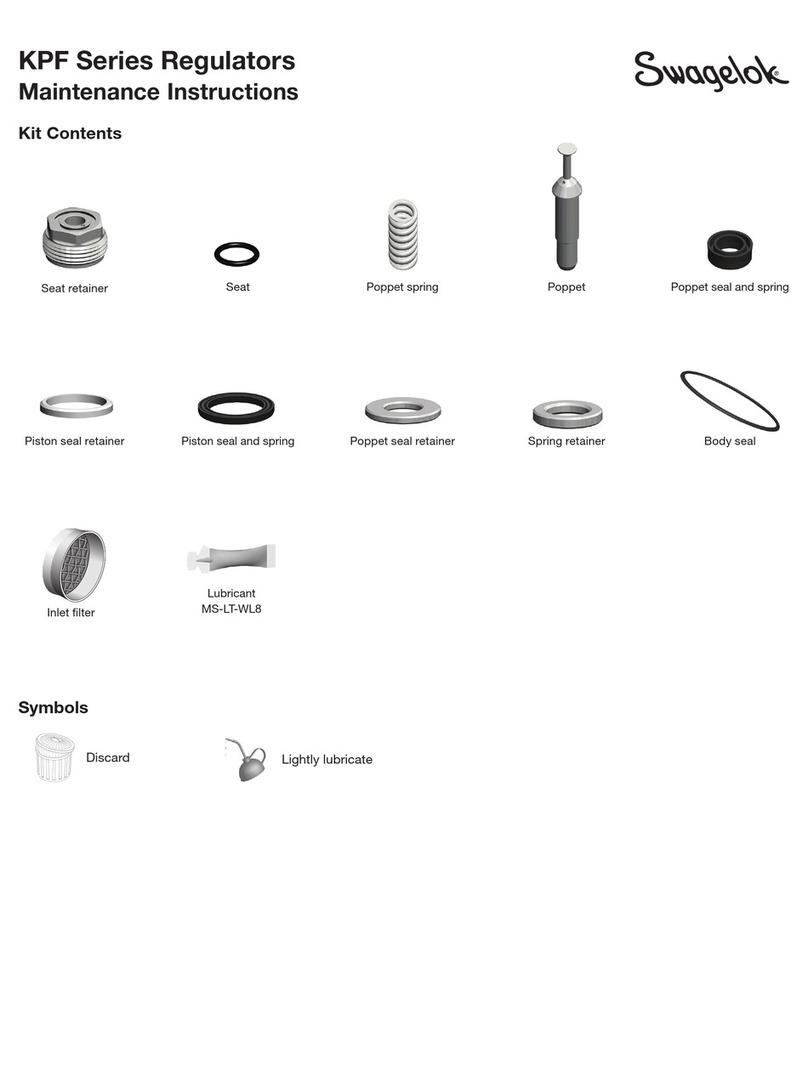

Swagelok KPF Series Technical specifications

Swagelok

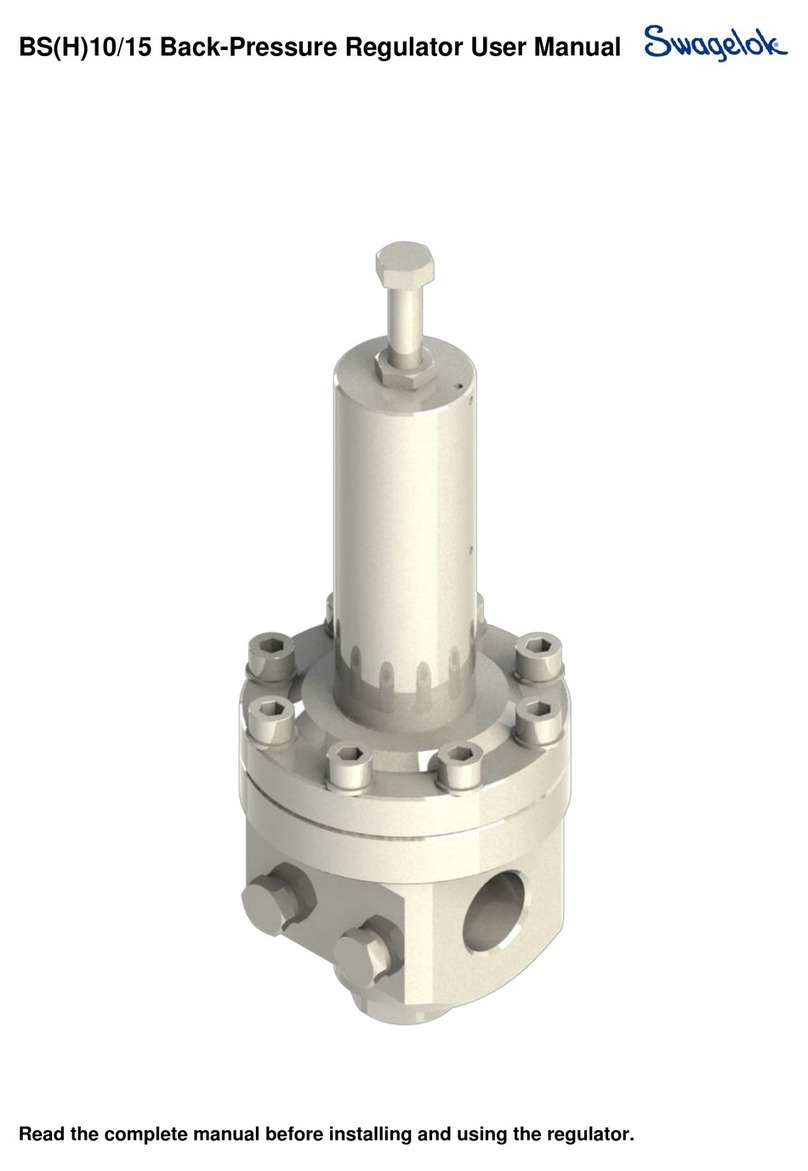

Swagelok BSH 10 Series User manual

Swagelok

Swagelok RHPS Series User manual

Swagelok

Swagelok RHPS Series User manual

Swagelok

Swagelok PRS15 User manual

Swagelok

Swagelok KFB Series Technical specifications

Swagelok

Swagelok RHPS Series User manual

Swagelok

Swagelok RHPS Series User manual

Swagelok

Swagelok RHPS Series User manual

Swagelok

Swagelok KPP Series Technical specifications

Swagelok

Swagelok KCP Series Technical specifications