A-96.250.211 / 171121

AMI Sodium P

4

4. Instrument Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.1. Installing the Reagent Bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.2. Installing the Regeneration Solution Bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.3. Establish Sample Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.4. Switch on Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.5. Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.6. Fill Tube of Automatic Regeneration Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.7. Perform a Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

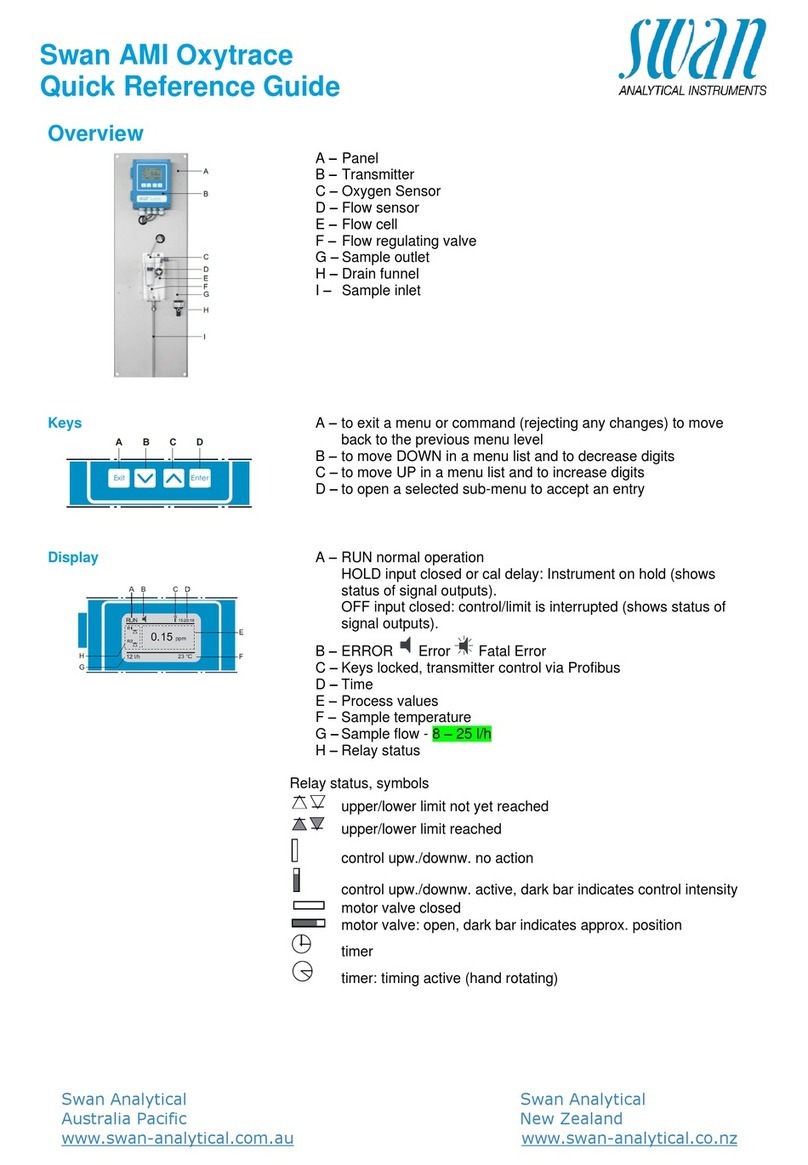

5.1. Keys, Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.2. Software Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.3. Changing Parameters and Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.4. Grab Sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.1. Maintenance Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.2. Stop of Operation for Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.3. Maintenance of Sodium Electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.4. Maintenance of Reference Electrode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.5. Maintenance of pH Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.6. Maintenance of Solenoid Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.6.1 2nd Sample Stream Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.6.2 Automatic Regeneration Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.7. Maintenance of Flow Cell and Constant Head. . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.7.1 Cleaning the Flow cell. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.7.2 Cleaning the Constant Head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.8. Replacing the Air Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6.9. Preparing the Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6.10. Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.10.1 pH Process Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.10.2 Standard Sodium 1-Point Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.10.3 2-Point Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.11. Tube Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6.11.1 Tube Numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6.11.2 Replacing the Reaction Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.11.3 Replacing the EPDM Seal and the Air Inlet Tube. . . . . . . . . . . . . . . . . . . . . . 82

6.12. Longer Stop of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

7. Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7.1. Error List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7.2. Automatic Regeneration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

7.3. Replacing Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88