SWL Pre-Delivery Check List Page 2 Revision A

III. CONTROLS

Controls easy to operate from driver’s seat.

Movement of controls correct, per installation instructions.

IV. HYDRAULIC INSTALLATION

Correct hydraulic oil level in reservoir, per installation instructions.

Inspected for leaks.

Any abnormal noise during hoist operation?

YES NO

If yes, please describe:

With engine operating @ 1,000 RPM, record the following information:

Cycle time for dump mode:

Seconds Up Seconds Down

Cycle time for load/unload mode:

Seconds to Unload Seconds to Load

Filter pressure:

PSI

Main pressure, controls in neutral:

PSI

Main relief pressure when extending

jib cylinder (bottomed out):

PSI

Main relief pressure when extending

lift cylinders (bottomed out):

PSI

NOTE: Connect pressure gauge to fitting provided on the inlet section of the Hydraulic Control Valve (Ref. Part

No. 10P37, fitting on Hydraulic Pump Circuit Drawing found in the Parts List section of the Hoist’s Parts &

Operations Manual).

V. OPERATION

Jib operates freely in both directions.

Jib cannot be extended or retracted when raised in dump position or when pivot joint is tilted in unload

position. Both safety hooks are fully engaged when jib is extended.

Parts & Operations Manual is in the cab.

Lubricate sliding jib and all grease zerks per installation instructions.

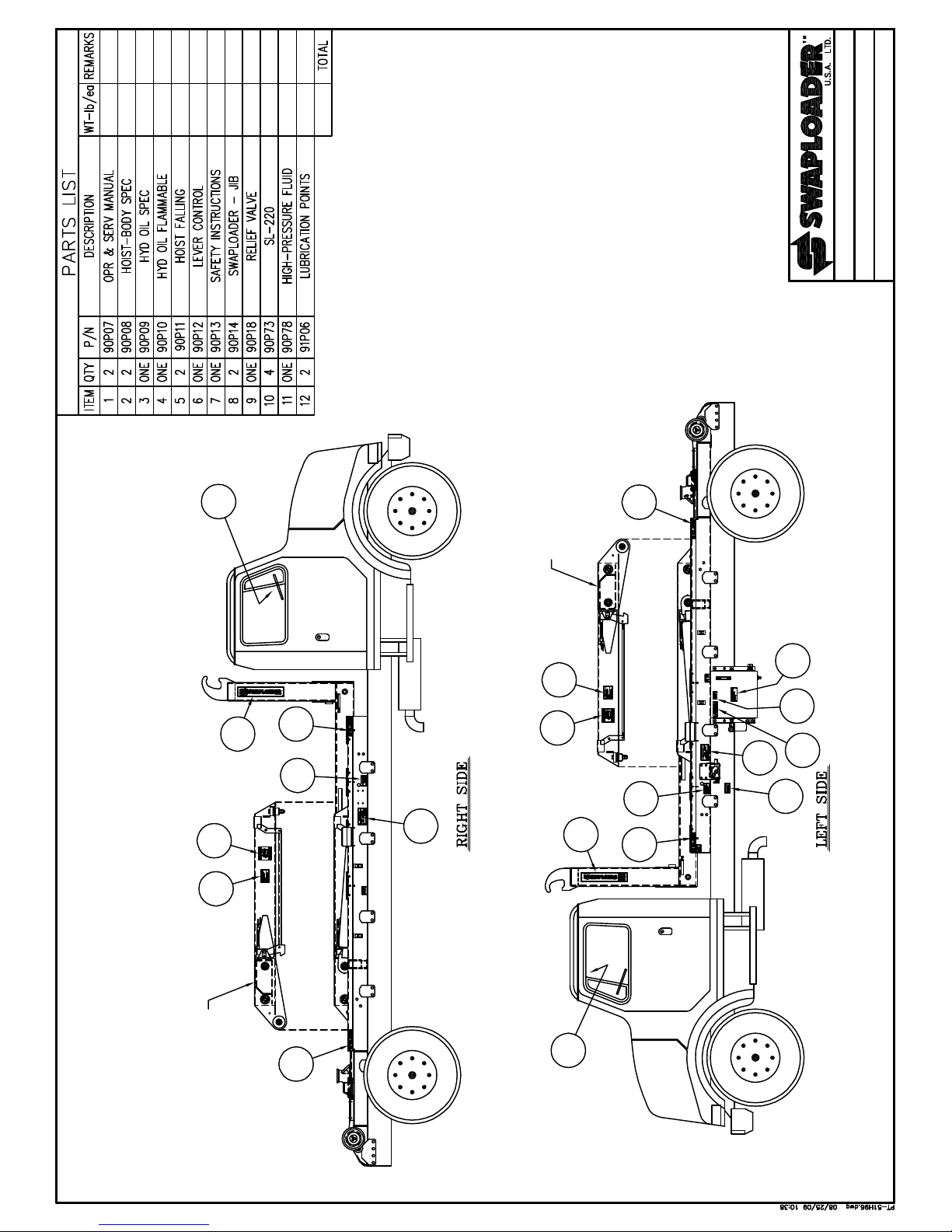

VI. DECALS

All safety decals and product decals installed per enclosed decal drawings (found attached to the inside

of the hoist’s Parts & Operations Manual cover or at the back of the Parts List section in the Manual).

Additional Comments:

COMPLETE & SAVE TO YOUR COMPUTER. RETAIN A COPY FOR YOUR FILES.

ONCE COMPLETE, FAX (515-313-4426) OR EMAIL (sales@swaploader.net) A COPY BACK TO SWAPLOADER!

1800 NE Broadway Ave., Des Moines, IA 50313 • www.swaploader.com • Toll Free: 888-767-8000