www.swarco.com

SWARCO TRAFFIC SYSTEMS GMBH, Niederkircher Straße 16, D-54294 Trier, Germany

2/39

Content

1Introduction.................................................................................................................................... 4

1.1 About this manual.................................................................................................................... 4

1.2 Usage according to regulations............................................................................................... 4

1.3 Label ........................................................................................................................................ 5

1.4 Further documentation ............................................................................................................ 5

1.5 Symbols ................................................................................................................................... 5

1.6 Safety instructions ................................................................................................................... 6

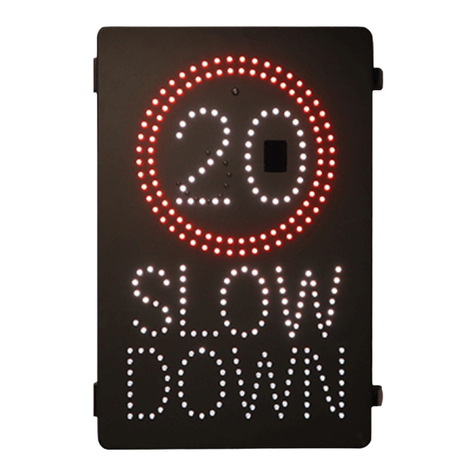

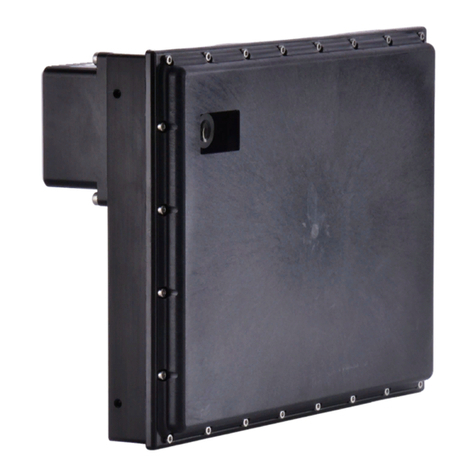

2Product description....................................................................................................................... 7

2.1 General .................................................................................................................................... 7

2.2 Overview of the essential product characteristics ................................................................... 9

3Installation of the SW2224.......................................................................................................... 10

3.1 Installation and start-up of the unit ........................................................................................ 10

3.2 Overvoltage protection and loop diagnosis ........................................................................... 10

3.3 Connection of the feeder cable.............................................................................................. 10

3.4 Parameterizing the traffic data acquisition ............................................................................ 11

4Operating the SW2224 with LoopMaster................................................................................... 13

4.1 General .................................................................................................................................. 13

4.2 Functionalities........................................................................................................................ 13

5Display and operating elements at the front panel.................................................................. 15

6Alignment and error diagnosis .................................................................................................. 17

6.1 Alignment............................................................................................................................... 17

6.2 Error detection and troubleshooting ...................................................................................... 17

6.3 Automatic calibration and control of vehicle detection .......................................................... 19

7Parameters and functionality ..................................................................................................... 21

7.1 Significance of the channel parameters ................................................................................ 21

7.1.1 Channel function............................................................................................................ 21

7.1.2 Frequency range............................................................................................................ 21

7.1.3 Loop type and loop distance.......................................................................................... 24

7.1.4 Vehicle length correction ............................................................................................... 24

7.1.5 Detection of wrong way drivers ..................................................................................... 25

7.1.6 Address data bus........................................................................................................... 25

7.1.7 Sensitivity / measuring time........................................................................................... 25

7.1.8 Hold time........................................................................................................................ 26

7.1.9 Channel flags................................................................................................................. 26

7.1.10 Maximum loop alignment duration................................................................................. 26

7.1.11 Noise threshold.............................................................................................................. 27

7.2 Significance of the device parameters .................................................................................. 27

7.2.1 Language service interface ........................................................................................... 27

7.2.2 Baud rate data bus ........................................................................................................ 27

7.2.3 Detector flags................................................................................................................. 27

7.2.4 LED turn-off time............................................................................................................ 27