3.1. Installation of the air heater/cooler in

the duct system

The unit is installed in the outdoor air duct when con-

nected as preheater/chiller. The air heater/cooler must

be mounted horizontally. Remember that the conden-

sate outlet must be connected to the building's drain-

age system. There should be at least 500 mm free space

in front of the hatch.

The condensate hose is connected to the condensate

outlet (G3/8"). The condensate is led off to a floor

drain or the like using a hose with an inner diameter

of at least 12 mm. The condensate hose (502130) is

available as an accessory for air heater/cooler W2504F.

The hose must not be led off directly to the drain. There

must be two water traps or a horizontal section on the

condensate hose. The damming height of the water

trap should be at least 100 mm.

Check that the condensate discharge outlet is not

3. Installation

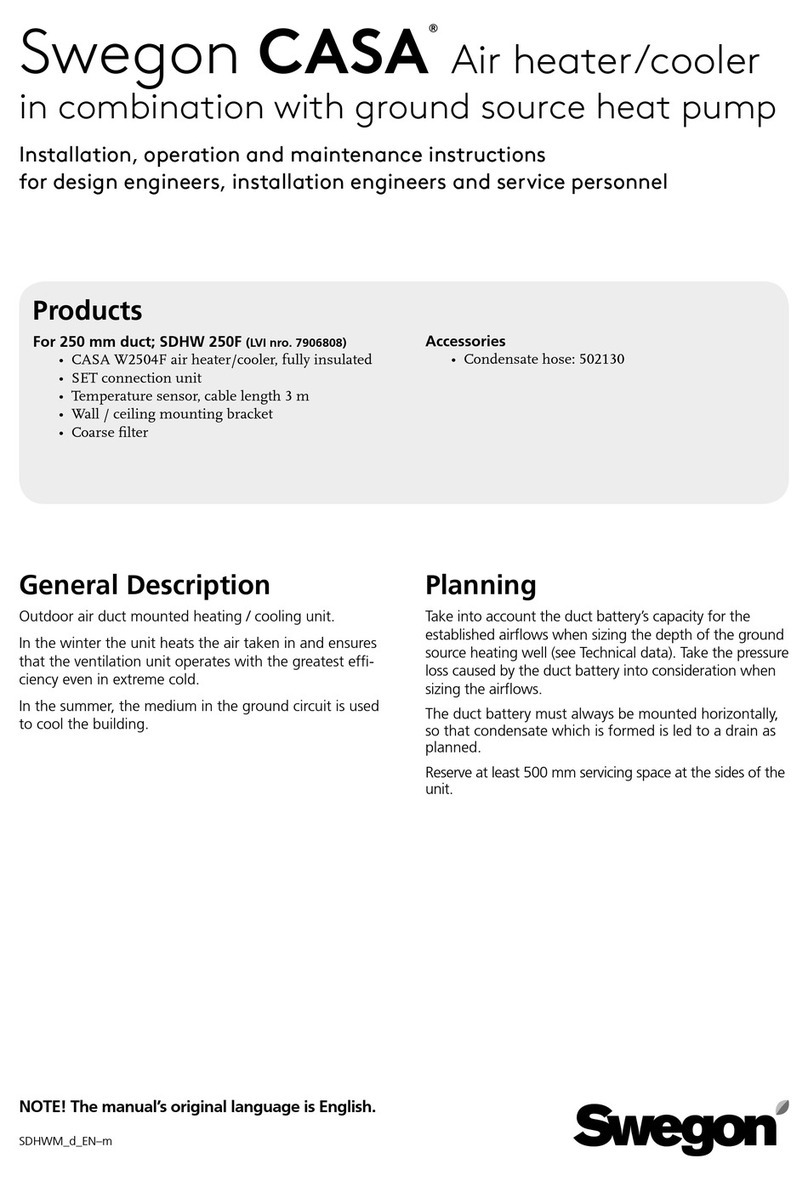

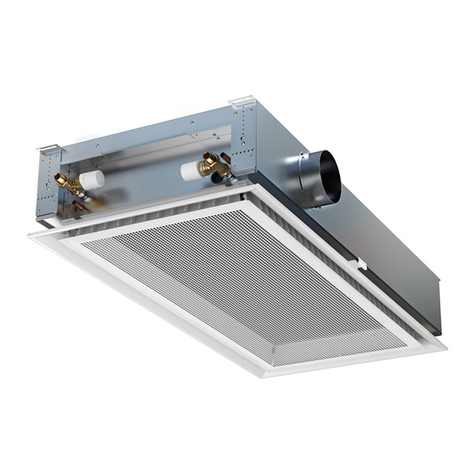

In the winter the air heater/cooler heats the air taken

in and ensures that the ventilation unit operates with

the greatest efficiency even in extreme cold. In the

summer, the medium in the ground circuit is used to

cool the building. The control technology in CASA

Smart ventilation units automatically enables the best

utilisation of the air heater/cooler all year round.

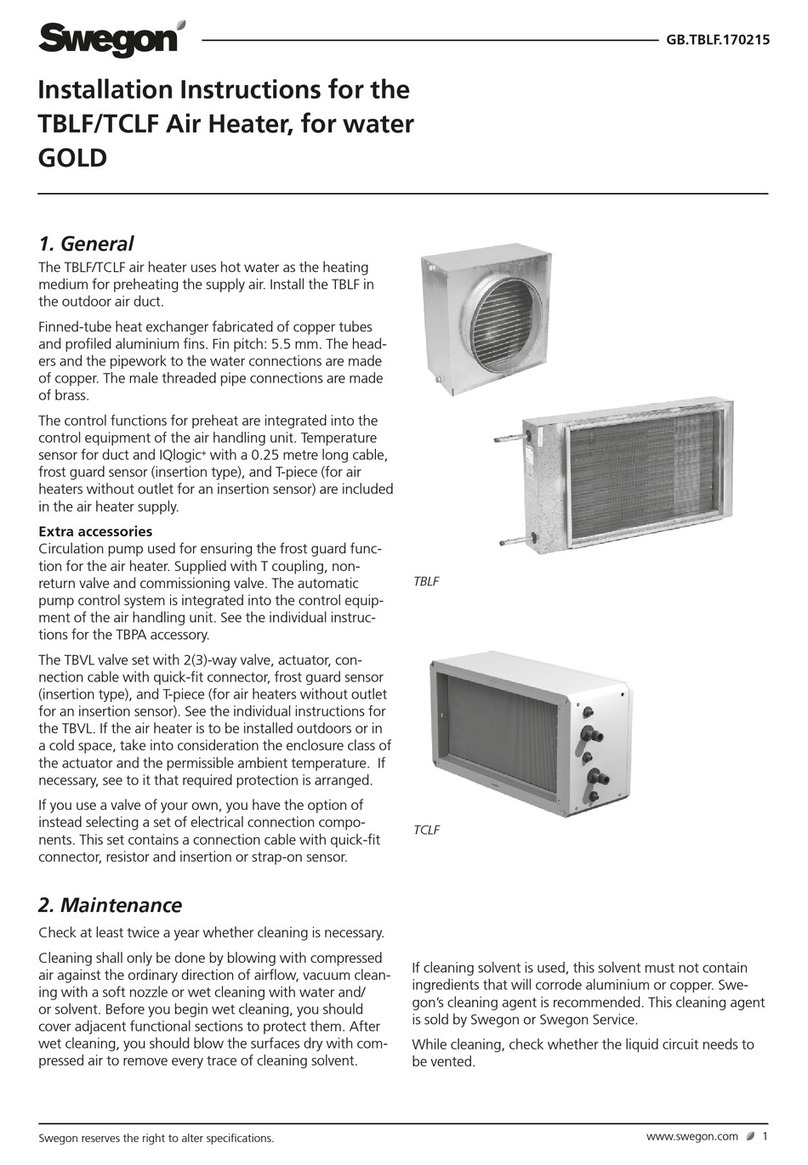

1. General Description

2. Planning

To observe during planning: when sizing the depth of

the ground source heating well, review the capacity

tables in the brochure and take into account the air

heater/cooler’s capacity for the established airflows. To

size the pump, find out the heating medium flow and

the air heater/cooler’s pressure loss. Take the pressure

loss caused by the air heater/cooler into consideration

when sizing the airflows.

The air heater/cooler must always be mounted

horizontally, as condensate is formed during the

summer and this must be led to a drain.

Reserve servicing space at the sides of the unit in the plans.

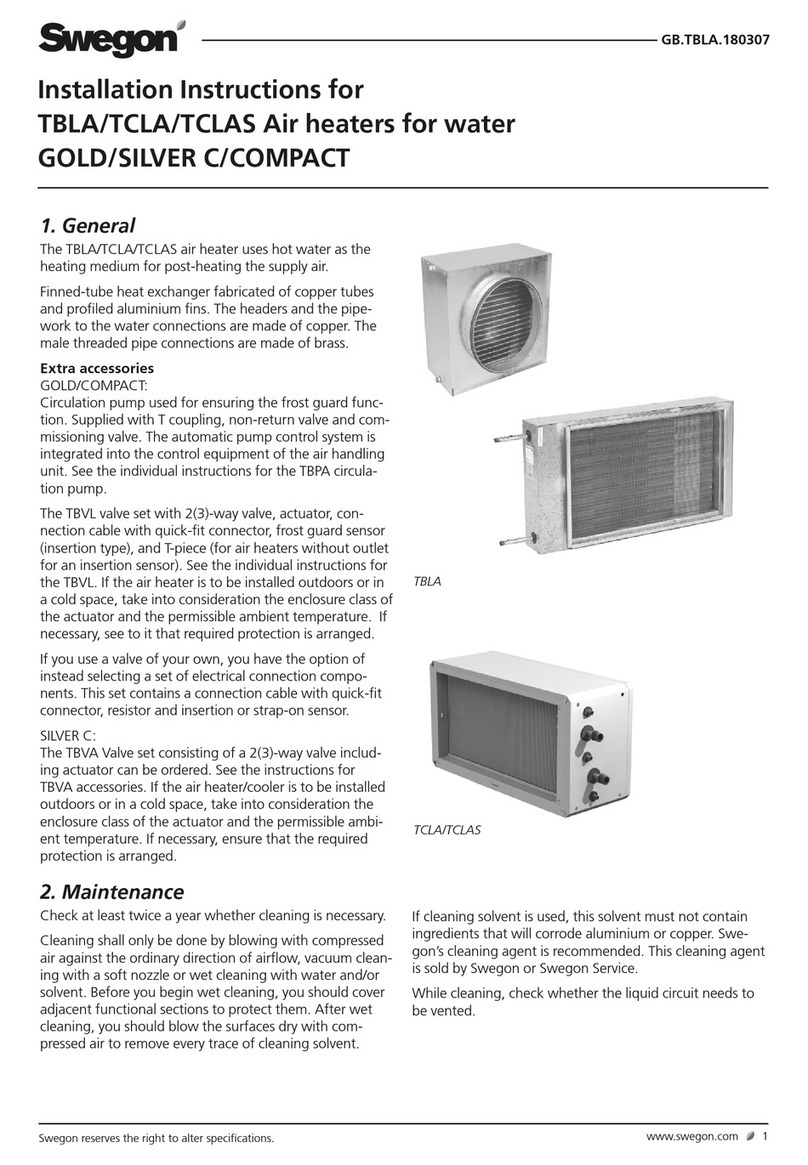

3.2. Pipe connections for the heating medium

The pipes for the air heater/cooler’s heating medium is

connected to the unit’s pipe connections (Cu 22 mm)

for the outgoing solution and the return solution.

Remember the need to vent the heating medium pipes

in connection with the pipe installation. The air heater/

cooler’s coarse filter must always be installed on the

unit’s outdoor side.

The following must be taken into consideration when

the air heater is connected to the pipe system:

1. The air heater/cooler’s connection pipes must not

be subjected to distortion or bending movements

when the connections are made. Counterhold with

a tool when assembling the couplings.

2. Ensure that the unit’s expansion forces or the pipe

system’s own weight does not load the connections

on the air heater/cooler.

3. To facilitate venting of the air heater/cooler,

heating medium is generally supplied through the

lowermost pipe on the heater/cooler. The venting

valve is normally placed at the highest point of the

pipe system.

4. The air heater/cooler and its connections must be

checked for leakage once the pipe system has been

completely filled.

clogged and check its outflow by pouring water on the

bottom of the ventilation unit.

The condensate pipe must be placed in a heated space.

A condensate pipe that is installed in a cold space

must always be insulated with at least 50 mm mineral

insulation or 30 mm cellular rubber insulation and fitted

with a heating cable.

The ducts are mounted on the air heater/cooler’s

Ø250 mm connection sleeves. The ducts are slid into

the sleeves and locked with pop rivets. Keep in mind

that the ducts’ insulation must run right up to the unit.

After the air heater/cooler, the supply air duct must be

insulated using 10 mm thick mineral wool in both the

heated and cold areas (remember moisture insulation).

The outdoor air duct, the ducts after the air heater/

cooler as well as the outgoing exhaust air duct must

also be insulated against moisture (for example with a

layer of plastic film above the layer with insulation or

cellular-rubber insulation).