EN

EN - 7

TECHNICAL DATA

ENGINE

Type .....................single cylinder, 4 stroke

Cooling ................Liquid with double radiator

and heater fan

Bore ....................................3.94 in.

Stroke ...................................3.01 in.

Displacement ..........................36.6 cu.in.

Compression ratio .........................12,4:1

Starting ................................electric

TIMING SYSTEM

Type ..................double overhead camshaft

chain operated; 4 valve

Valve clearance (with engine cold)

Intake and exhaust .............0.004 ÷ 0.006 in.

LUBRICATION

Type ..........with lobe pump and cartridge filter

IGNITION

Type ........................Electronic, inductive

with adjustable advance (digital control)

Spark plug type...................... NGK CR8EB

Spark plug gap .................. 0.027 ÷ 0.031 in.

FUEL SYSTEM

Type .....................Electronic injection feed

PRIMARY DRIVE

Drive pinion gear.............................Z 32

Clutch ring gear .............................Z 75

Transmission ratio ..........................2,343

CLUTCH

Type .................oil bath multiple disc clutch,

hydraulic control

TRANSMISSION

Type ...................constant mesh gear type

Transmission ratio

1st gear ............................2,615 (z 34/13)

2nd gear ...........................1,812 (z 29/16)

3rd gear............................1,350 (z 27/20)

4th gear ...........................1,091 (z 24/22)

5th gear ..........................0,957 (z 22/23)

6th gear ..........................0,880 (z 22/25)

SECONDARY DRIVE “T”

Transmission sprocket .......................Z 15

Rear wheel sprocket .......................Z 38

Transmission ratio .........................2,533

Transmission chain dimensions..........5/8”x1/4”

SECONDARY DRIVE “X”

Transmission sprocket .......................Z 15

Rear wheel sprocket .......................Z 40

Transmission ratio ............................2,

Transmission chain dimensions..........5/8”x1/4”

FINAL RATIOS “T”

1st gear ...................................15,529

2nd gear ..................................10,762

3rd gear....................................8,016

4th gear ...................................6,477

5th gear ...................................5,679

6th gear ...................................5,225

FINAL RATIOS “X”

1st gear ...................................16,334

2nd gear ...................................11,318

3rd gear....................................8,432

4th gear ...................................6,814

5th gear ...................................5,977

6th gear ...................................5,496

CHASSIS

Type ......Single-beam, steel circular cross-section

pipes; rear chassis in steel

square cross-section pipes

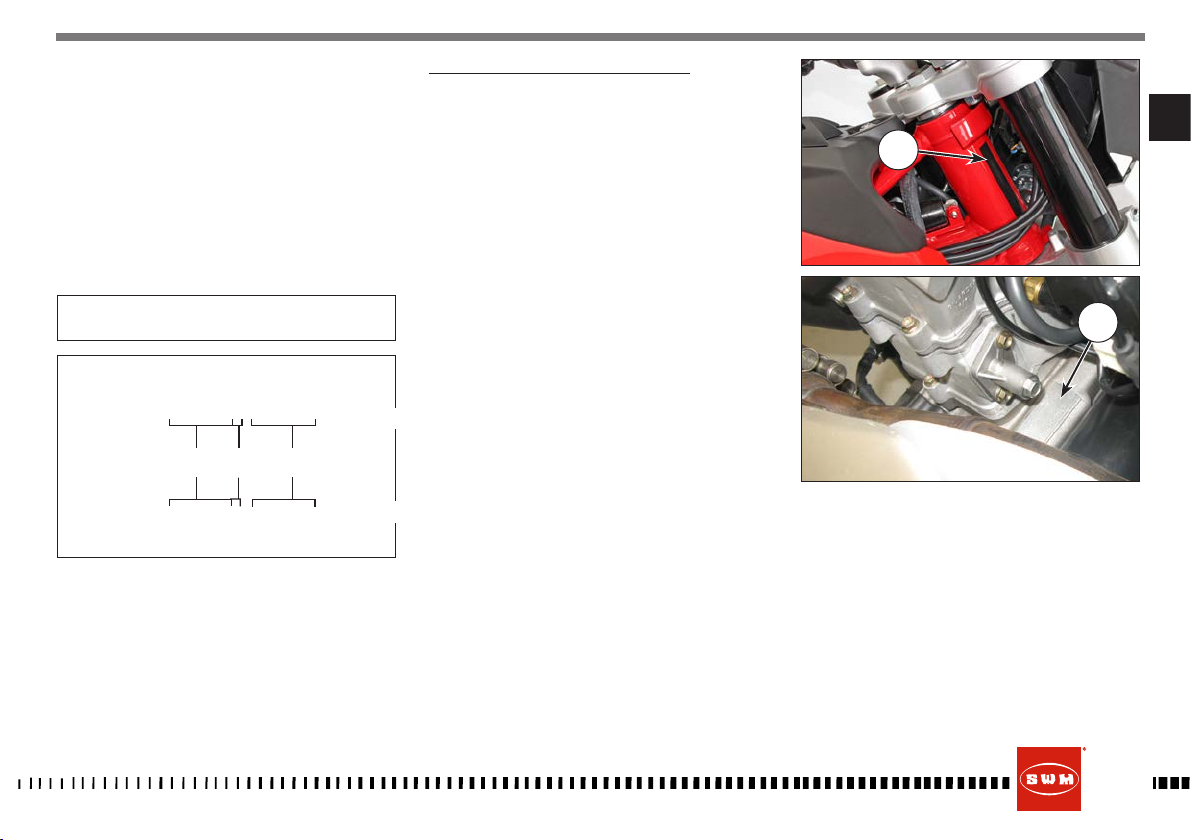

FRONT SUSPENSION

Type ....“Upside-down” telescopic hydraulic front

fork with advanced axle (adjustable in

compression and extension); tubes ø 1.69 in.

Leg axis stroke ..........................8.62 in.