2

1. INTRODUCTION

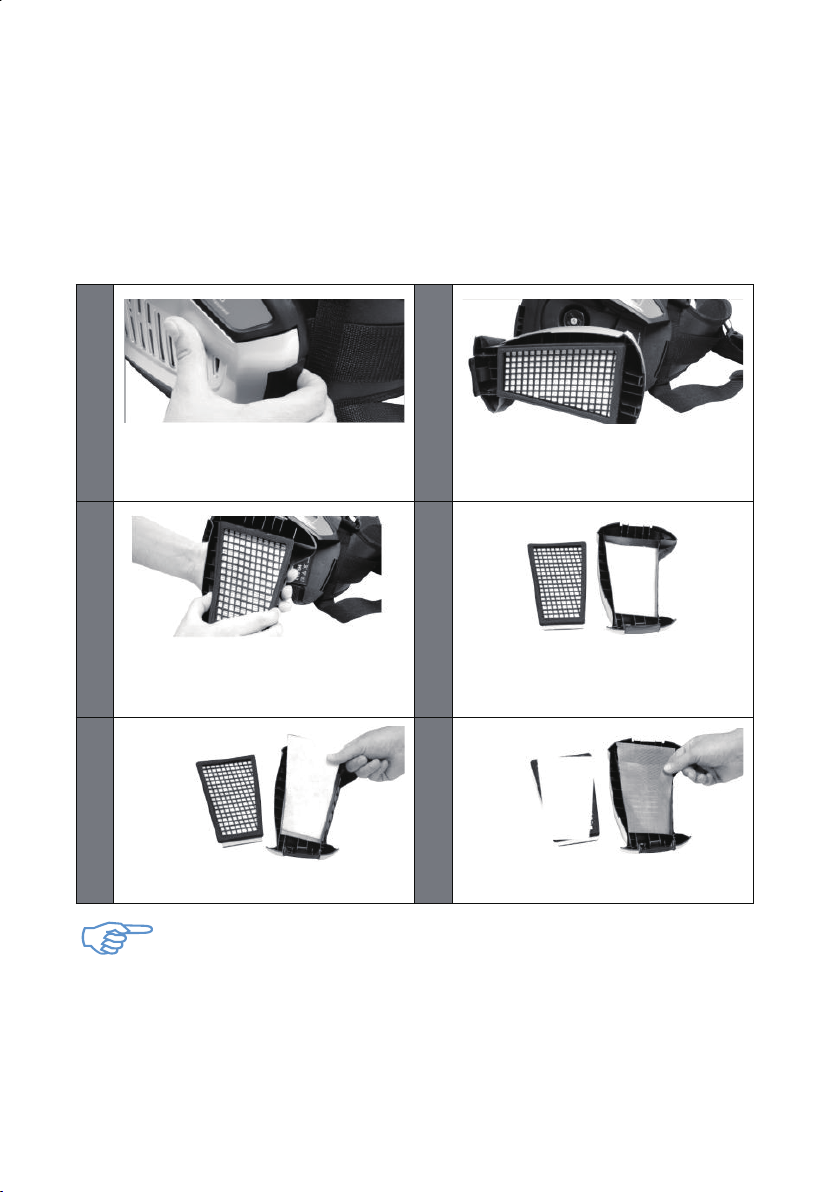

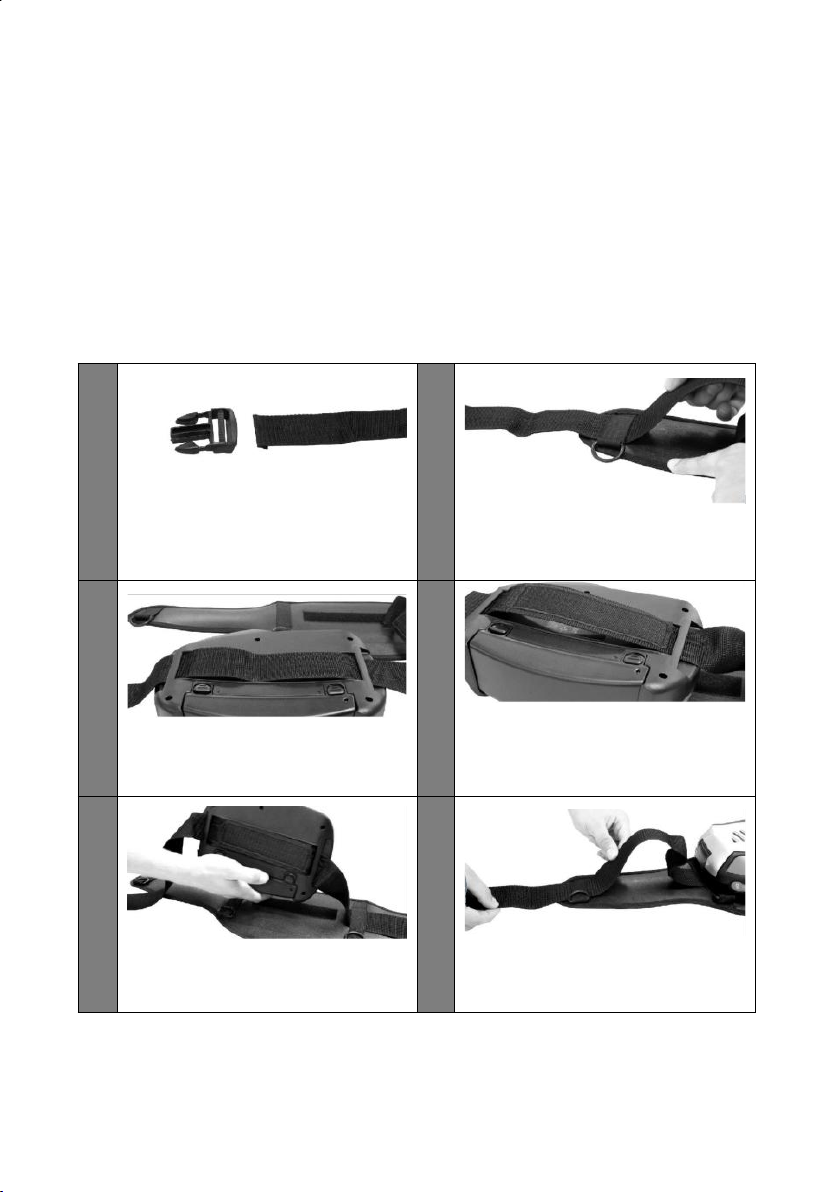

Respirator system is intended to be used to provide protection when the user working in

the contamination environment. The equipment is able to filter the contaminate air via

the filter build in to the blower and then supply fresh air from breathing tube to the

welding faceshield, so that the user can continually working in contamination

environment. It is a combined face and breathing protection device for increased safety

and comfort during welding. Please read these instructions carefully before unpacking.

For proper use, see user instructions or contact manufacturers for help.

2. APPROVALS

The system complies with the requirements of PPE Regulation 2016/425 and

European Standard EN 12941: 1998+A2:2008 class TH3 P R S L . The respirator

system is designed to provide a supply of filtered air via a breathing tube to a welding

headpiece. The equipment can be used in environment that requires a class TH3P

breathing protection device. It protects against articulate contamination.

All components used in respirator system must be manufacturer approved parts, and

must be used in accordance with the instructions in this manual.

1. The approval is not valid if the product is incorrectly used together

with non-approved parts or components.

2. Only the particle filter and pre-filter can be used together with this

system. Filters fromother manufacturersshould under nocircumstances

be used.

PAPR PRECAUTIONS

Notified Body: Vyzkumny ustav bezpecnosti prace, v. v. i., Jeruzalémská 1283/9, 11

0 00 Praha 1, Czech Republic (Notified body number 1024)

3

3.WARNING AND LIMITATIONS TO USE

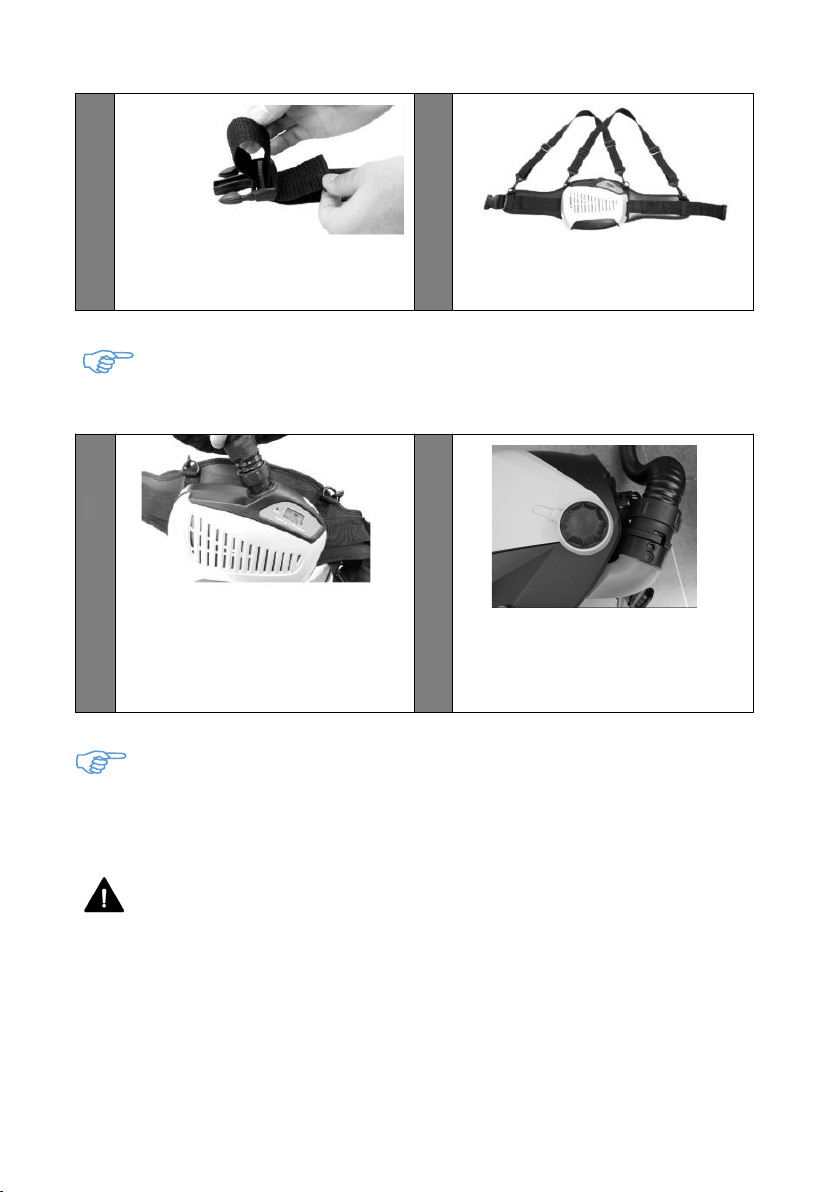

Before each use, inspect the respirator system for damage and verify it operates

properly. Before using the respirator system, test air flow to verify it is providing an

adequate volume of air.

Always wear the respirator system and do not remove the head top or turn off the air

filter unit until outside the contaminated area, otherwise, there is a risk of high

concentration of CO2and oxygen level in the head top will fall, thus little or no protection

is given.

If you are not sure about the concentration of pollution, or about equipment performance,

ask the industrial safety engineer.

he manufacturer is not responsible for injury due to the following

incorrect use or incorrect choice of equipment.

Warning:

This respirator devices should be used with well trained person and qualified person

only.

Before using the devices ensure you have understood that at very high work rates the

pressure in the device may become negative at peak inhalation flow.

Before and during using the devices, attention shall be drawn to possible incorrect use

and, where appropriate, the possibility of looped hoses and/or cables becoming caught

up.

Before or during using the devices if the devices in the power-off state little or no

respirator protection is to be expected, and that this is considered to be an abnormal

situation.

Please leave the work place and remove the headgear, when the devices in the

power-off state a rapid build-up of carbon dioxide and depletion of oxygen within the

hood may occur.

The filters shall only be fitted to the turbo unit and not directly to the helmet/hood.

The user should not confuse the markings on a filter relating to any standard other than

EN 12941 with the classification of this device when used with this filter.

DO NOT use SparX Air with the blower unit switched off.