ALUMTIG 200

ALUMTIG

QUICK REFERENCE GUIDE

™

200

FRONT PANEL DIGITAL DISPLAY

TIG DCEN

VRD

Voltage Reduction Device reduces

maximum unloaded voltage of output

terminals to safe levels (Stick only).

2T/4T Trigger Modes

To operate with the torch switch, select 2T or 4T (2T Double ended arrow 4T separate arrows). For 2T operation,

simply press and hold the switch. The panel program will cycle automatically. When the switch is released, the arc

will downslope and terminate with post gas flow. When in 4T mode, the switch is pressed, and held to start the

pre-flow and the start amps part of the cycle. When released, upslope begins and continues until the amps are

raised to the preset welding amps. When pressed and held again, downslope starts and ramps down to the end amp

stage. When released, the arc terminates, and post flow begins. Remote torch switch (0) is the selected machine

setting (10) 0 Amps.

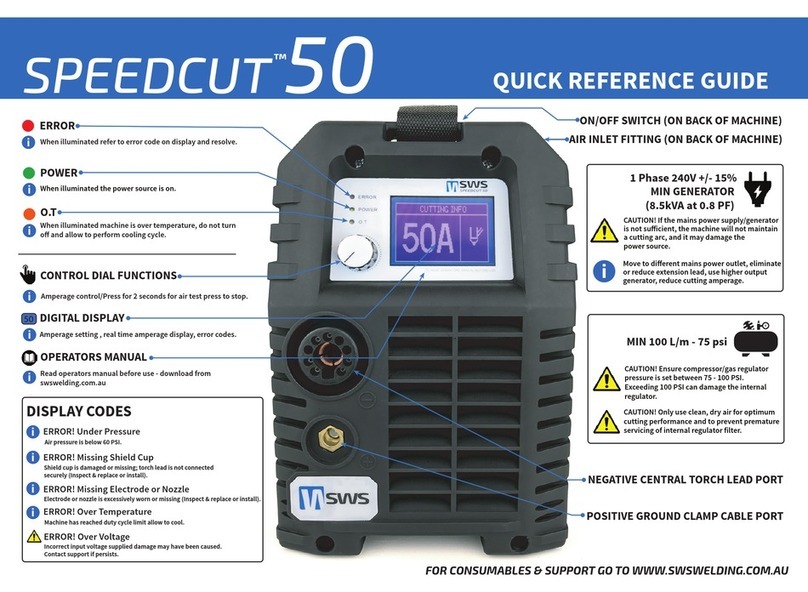

Power LED

When illuminated the power source is turned on.

Error LED

When illuminated refer to error code on display

and resolve.

Control Dial

1. Rotate to choose setting.

2. Press to select setting.

3. Rotate to adjust setting.

4. Press to store setting.

NOTE: Settings will be stored in the USER

profile chosen at first menu (TIG only).

Argon Outlet

Connect torch gas line and tighten.

NOTE: In most Stick welding

applications DCEP (Direct

Current Electrode Positive) is

used. In some cases when

welding very thin material

using DCEN can be an

advantage.

NOTE: In almost all TIG

welding applications DCEN

(Direct Current Electrode

Negative) is used.

100% Argon 6-15 L/min

depending on conditions.

Torch/Foot Pedal Control

Position locating cut out facing to the top align

and push in to connect. When using the foot

pedal just leave torch switch to the side.

Stick DCEP or DCEN

HF or Li TIG

Weld using Li TIG (for DC only) which requires contact with the metal to initiate the arc or High Frequency Start which

allows non contact starting of the arc (for AC and DC). (HF symbol as pictured).

Welding Amps

This displays the Amps in real time while welding and will hold for 5 seconds aer weld is complete.

Pulse Base Amps

Governs the lower(base or background current) amp value during the pulse cycle.

Pulse Time On (Balance) %

Defines the duty cycle (balance) of the pulse, by dividing the amount of time the pulse stays in the lower or upper

stage of the pulse.

AC Frequency

Governs the number of times per second that the current alternates in AC mode. To achieve greater arc focus

(constriction) and increase puddle agitation while welding in AC mode, increase AC frequency.

Pulse Frequency Hertz (Pulses per second)

Governs the number of times per second that the current alternates in AC mode. To achieve greater arc focus

(constriction) and increase puddle agitation while welding in AC mode, increase AC frequency.

AC Balance

Defines the percent of Electrode Positive (EP) used during AC welding to provide the cleaning action. This divides the

time that the AC cycle spends in (EP) or (EN) during one full AC cycle. Too much cleaning action will result in tungsten

balling or splitting. Too little cleaning can result in dirty, sooty welds and even a dull weld appearance. Higher DCEP

percentage means a greater cleaning action 65% is a good starting point.

AC or DC

The unit features AC/DC operation and uses advanced square wave for AC that has excellent wet in, and arc

controllability.

Welding Sequencer

When the Pro USER mode is selected from the main menu you have complete control over the welding parameters.

Main Menu

AC: 65% 120Hz

PRE-FLOW

START-AMPS

UPSLOPE

PULSE BASE AMPS

PULSE TIME ON %

PULSE FREQUENCY Hz

PULSE OFF AMPS (WELDING AMPS AUTO AC/AUTO DC MODES)

BASE AMPS

DOWNSLOPE

END-AMPS

POST-FLOW

- - - -

See back for recommended Amperage Values and Welding Techniques.

200A