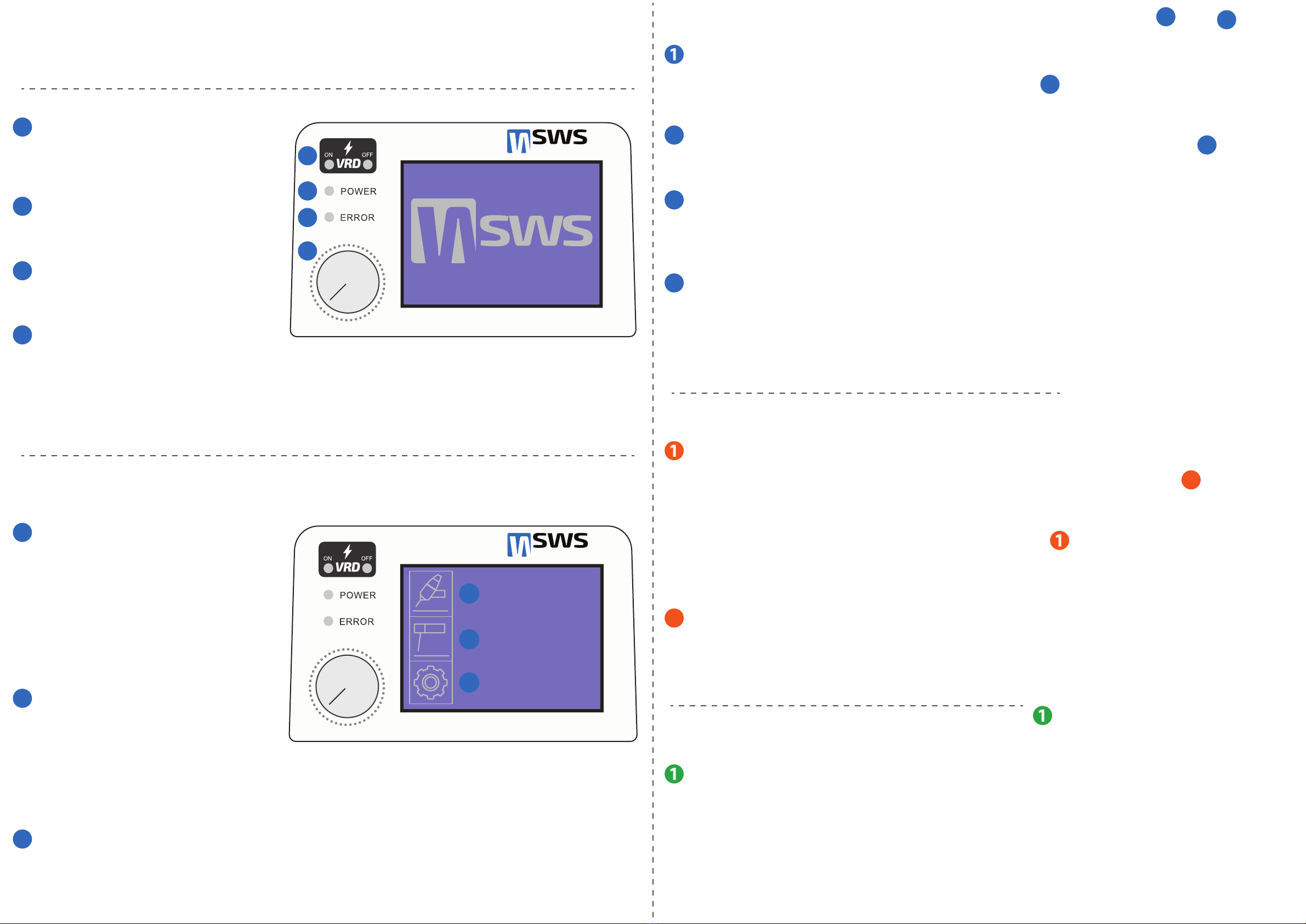

TIG (GTAW) Functions

Stick (MMA) PRO Functions

Function

PRE FLOW (1-10 Seconds)

Purpose

Provides shielding gas to the weld zone before striking an arc to prevent porosity and contamination. When using dierent torch cup

setups and long welding cables, the pre-flow can be increased to provide adequate shielding.

Function

START AMPS (10-200 Amps N/A EASY MODES N/A FOOT CONTROL)

Purpose

This parameter is used to set the start current for TIG. In 4T mode the Initial Current remains on until the torch trigger switch is released

aer it has been depressed. In 2T mode this is the Initial Current for the Up Slope current ramp.

Function

UPSLOPE (0-10 Seconds N/A EASY MODES)

Purpose

This parameter is used to set the time for the weld current to ramp up from INITIAL current to BASE current.

Function

WELD AMPS (10-200 Amps)

Purpose

This parameter sets the welding current. In PULSE TIG mode, this parameter sets the PEAK current.

Function

PULSE BASE AMPS (10-200 Amps)

Purpose

In PULSE TIG mode, this parameter sets the BASE current.

Function

DOWNSLOPE (0-10 Seconds N/A EASY MODES)

Purpose

Down Slope will ramp amps “down” from the welding amp value to the end amp value to give time to fill the crater le at the end of the

weld bead. Can also be used in the 4T mode to help with heat control by briefly tapping the switch to cool o the weld before tapping it

again to restart the up slope sequence before the arc reaches the end amp stage.

Function

END AMPS (10-200 Amps N/A EASY MODES N/A FOOT CONTROL)

Purpose

Sets the final or minimum current before the arc is terminated. Used for filling craters at the ends of the weld and crack prevention.

Function

PULSE TIME ON (10-90% NA EASY MODES)

Purpose

The pulse consists of two stages: Welding amps (upper /Peak) and Pulse amps (lower/background current). This is represented by a % of

total time the pulse spends in the pulse amp stage of the cycle during one full pulse. The feature can be used to increase or decrease

pulse amp time relative to the welding amp time of the cycle to help manage heat input.

Function

HOT START (0-60 Amps)

Purpose

Sets the starting amps to reduce sticking of the electrode during the arc strike phase.

Stick (MMA) AUTO Functions

Function

ELEC DIA (2-5mm)

Purpose

Machine automatically adjusts amps relevant to the diameter of electrode being used.

Function

Amps Fine Tuning (-20-20%)

Purpose

Fine tunes the amps for the metal being welded.

Function

WELD AMPS (10-200 Amps)

Purpose

Welding amps define the top limit of amps at which the machine has been programmed to operate.

Function

ARC FORCE (0-99%)

Purpose

Controls the arc response when an arc is held short and voltage begins to drop. Arc force automatically compensates by modifying the

volt/amp curve to maintain the energy needed to weld. Represented as a percent of available arc force amperage.

Function

PULSE FREQUENCY (1-500Hz NA EASY MODES)

Purpose

Represented by Hertz (Hz), the pulse frequency defines the actual number of times each second the pulse makes one complete cycle

between welding amps (peak/high amp value) and pulse amps (background/low amp value).

This is also commonly referred to as Pulses Per Second (PPS). Low pulse frequencies are ideal for timing the point where filler metal is

added. This helps improve appearance and uniformity. Higher pulse frequencies are useful for welding seams and edges of thin material

and for better penetration on thicker metals.

Function

HF ON/OFF

Purpose

HF - High Frequency Start which allows non contact starting of the arc or when o (li tig) requires contact with the metal to initiate the

arc (for AC and DC). (HF is selected when symbol is not striked out) The li start function on the ALUMTIG 200 provides a cold electrode

for safety, and prevents accidental starts.

Function

AC BALANCE (50-98% NA EASY MODES)

Purpose

Controls arc cleaning action when welding on AC. Adjusting the % electrode negative (EN) AC wave controls the width of the cleaning

zone surrounding the weld. Lower percentage AC balance more cleaning action but less penetration. Higher percentage AC balance less

cleaning action but more penetration. PRO TIP: Typically a range between 65% - 75% is used.

Function

AC FREQUENCY (50-98% NA EASY MODES)

Purpose

Governs the number of times per second that the current alternates in AC mode. To achieve greater arc focus (constriction) and increase

puddle agitation while welding in AC mode, increase AC frequency. This allows pinpoint use on thin materials, and helps penetration on

thicker materials. Ideal adjustment range is usually between 80-120Hertz. For comparison most transformer welders operate on 60 Hz.

Greater arc control and stability can be achieved through the higher frequency range oered by this welder. Lower Frequencies will

widen and soen the arc and reduce the level of control.

Function

2T, 4T, TACK CONTROL (0.1 - 10 Seconds)

Purpose

2T MODE: Press and hold the switch. The program will cycle automatically. When the switch is released, the arc will

downslope and terminate with post gas flow.

4T MODE: Switch is pressed and held to start the pre-flow then start amps part of the cycle. When released, upslope

begins and continues until the amps are raised to the preset welding amps. When pressed and held again,

downslope starts and ramps down to the end amp stage. If released before downslope ends program will cycle to main amps if released

aer downslope ends the arc terminates, and post flow begins.

TACK CONTROL: Select this mode to control the arc on time for precision tack welds.