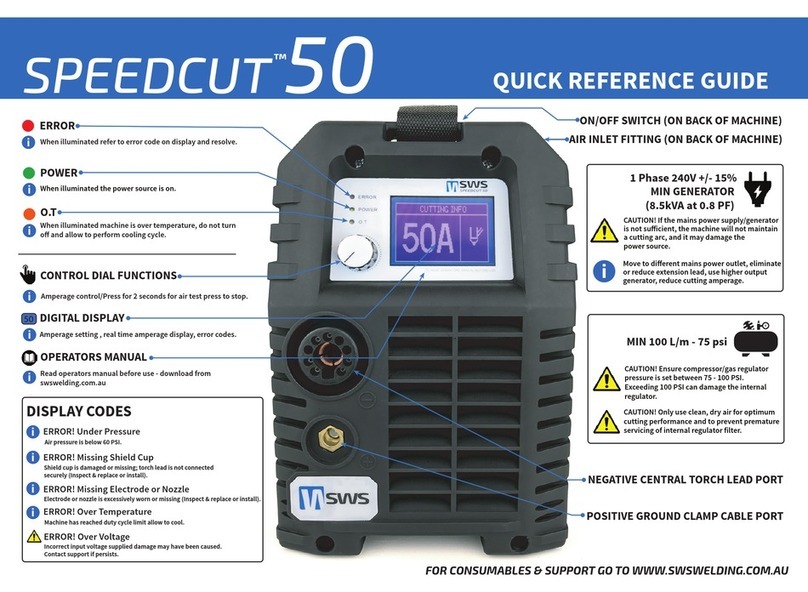

SPEEDCUT 50

SPEEDCUT 50

SPEEDCUT 50 OPERATING MANUAL 1

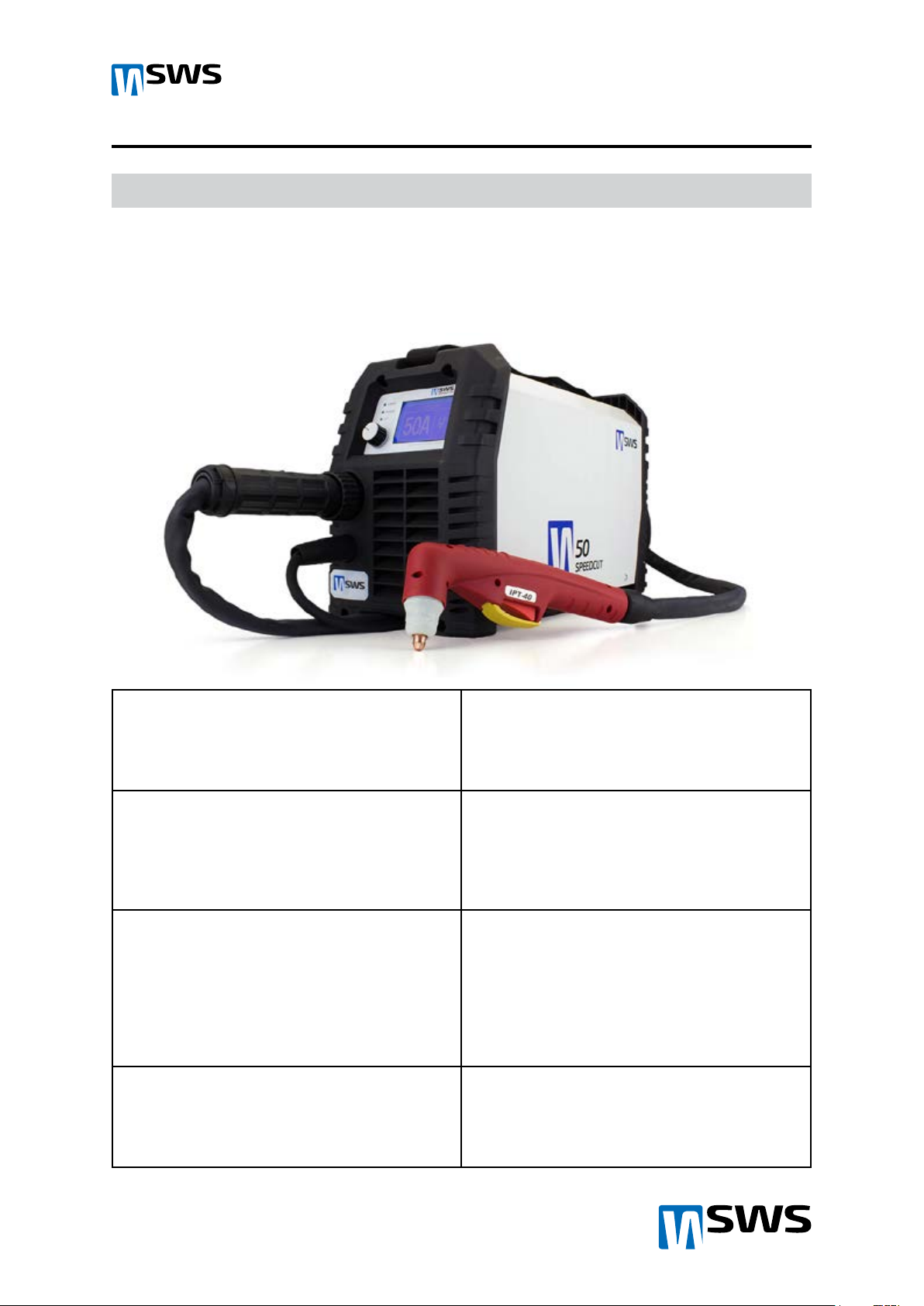

INTRODUCTION

1.0 Welcome

The SWS SPEEDCUT™ 50 is one of the highest quality and most aordable plasma systems on the Australian

market for cutting and gouging of all conductive metals. Featuring pilot arc with auto ignition and automatic

air regulation for optimum performance, you can now depend on a machine that cuts all day at its rated

cutting capacity and to pack more punch when you need it most.

Latest Inverter Technology

Embedded microprocessor with Infineon

components delivers ultimate durability and perfect

cutting characteristics.

Revolutionary Digital Display

Large high visibility durable display allows easy

viewing from a distance and continually provides

you with necessary feedback for optimum cuts.

Smart Programming

The system programming tells you when it’s time

to change consumables, let it cool if the duty cycle

is reached and gives constant feedback with real

time cutting amps displayed maintaining optimal

performance and cut quality.

Pilot Arc

With pilot arc, you benefit from being able to

cut rusty and painted metals while significantly

increasing consumable life.

Automatic Pilot Arc Restart

This feature gives you the ultimate in eiciency by

automatically controlling the pilot arc when cutting

expanded metal or multiple cuts. The pilot arc will

switch on and o when cutting expanded metal

and provides maximum performance when cutting

thicker metal. You benefit from this with less hand

fatigue and the best cutting performance.

Thermal Overload Protection

You can depend on your SWS machine to withstand

harsh working conditions. Thermal overload

protection will kick in once the 50% duty cycle

limit is reached (40° C). Duty cycle will increase as

environmental temperature decreases.

Highly Portable

Dependable IGBT inverter technology ensures a

highly portable and lightweight unit weighing only

11kg.

Meets the Highest Standards

Meets and exceeds the latest Australian, NZ and

International electrical and electromagnetic

compatibility standards. AS60974.1:2006,

IEC60974.10, CE