1/11

Quick Start Guide

Control I/O To download the latest version of Studio Matrix Designer, the Windows application

that controls all Studio Matrix hardware, go to: www.airtoolsaudio.com

What Ships in the Box

R A Control I/O hardware device.

R One PS-5 switching power supply

which provides 15 volts DC @ 1.33

amperes. NOTE: The PS-5 will accept

a 100-240 VAC input. A power cable for

domestic use is supplied for the PS-5.

Export customers should supply the

appropriate substitute cable for their

locale.

R This Quick Start Guide.

R

An RJ-45 Incompatibility Warning sheet.

What You Need to Provide

R A Windows PC with 300MHz or higher

Pentium and:

• WIN 98SE, ME, 2000 or XP.

• 10-15 MB free storage space.

• 1024x768 graphics capability.

• 16-bit or higher colors.

• CD-ROM drive or Internet connection.

• 64MB RAM (WIN 98SE/ME), 128MB

RAM (WIN 2000/XP).

R Shielded twisted pair wire to connect

the Control I/O RS-485 port to the

RS-485 port of a master Studio Matrix

audio input or output hardware device.

R CAT-5 cables to connect the Control I/O

to any ARC(s).

R External controls (pots, switches,

encoders, etc.) and hook up wire as

necessary.

Getting Help

Studio Matrix Designer, the Windows

application that controls all Studio Matrix

hardware, includes a help module which

acts as a complete user’s guide for both

hardware (including the Control I/O) and

software. A printable copy is also available

at www.airtoolsaudio.com.

If you have questions beyond the scope

of the help module, contact our Customer

Support Group in the following ways:

Tel (425) 778-7728

8:00 am to 4:30 pm

Monday through Friday,

Pacific Time

Email tech@airtoolsaudio.com

Web www.airtoolsaudio.com

This device complies with part 15 of the FCC

Rules. Operation is subject to the following

two conditions: (1) This device may not cause

harmful interference, and (2) this device must

accept any interference received, including

interference that may cause undesired

operation.

This Class B Digital apparatus meets all

requirements of the Canadian Interference-

Causing Equipment Regulations

Cet appariel numerique de la classe B respecte

toutes les Exigences du Reglement sur le

materiel brouilleur du Canada.

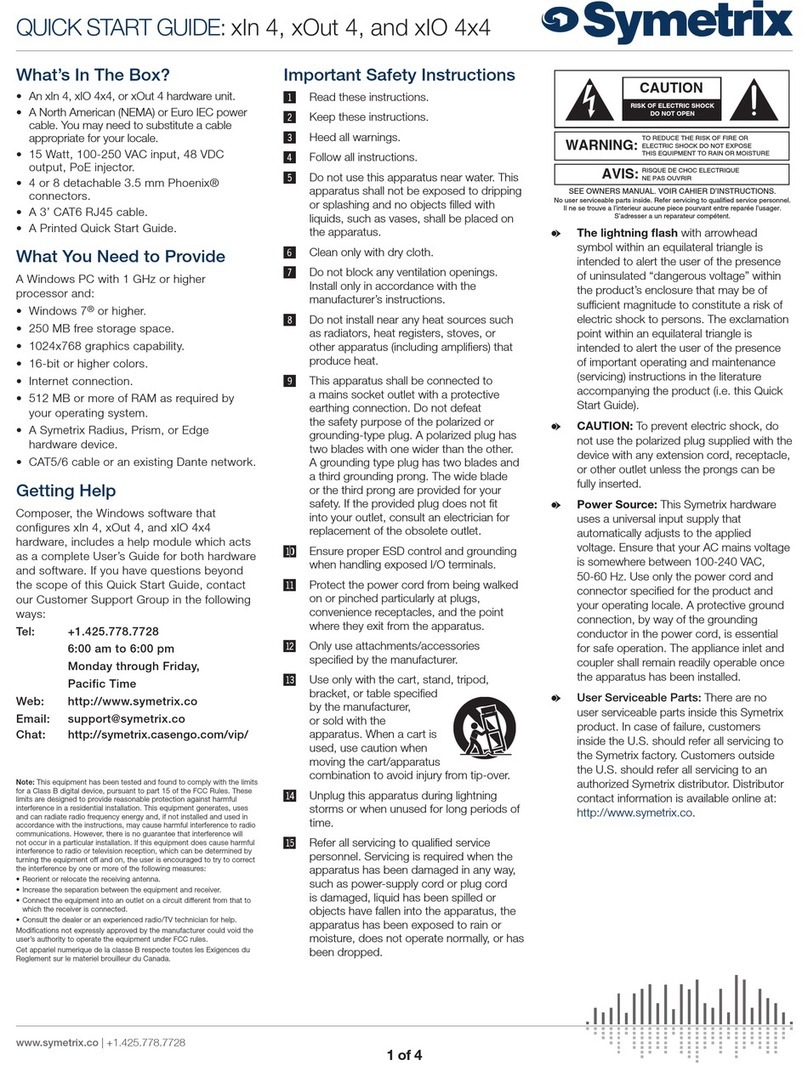

Important Safety

Instructions.

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with dry cloth.

7. Do not block any ventilation open-

ings. Install only in accordance with

the manufacturer’s instructions.

8. Do not install near any heat sources

such as radiators, heat registers,

stoves, or other apparatus (including

amplifiers) that produce heat.

9. Do not defeat the safety purpose of

the polarized or grounding-type plug.

A polarized plug has two blades with

one wider than the other. A grounding

type plug has two blades and a third

grounding prong. The wide blade or

the third prong are provided for your

safety. If the provided plug does not

fit into your outlet, consult an electri-

cian for replacement of the obsolete

outlet.

10. Protect the power cord from being

walked on or pinched particularly at

plugs, convenience receptacles, and

the point where they exit from the

apparatus.

11. Only use attachments/accessories

specified by the manufacturer.

12. Use only with the cart,

stand, tripod, bracket,

or table specified by

the manufacturer, or

sold with the apparatus.

When a cart is used, use caution

when moving the cart/apparatus com-

bination to avoid injury from tip-over.

13. Unplug this apparatus during light-

ning storms or when unused for long

periods of time.

14. Refer all servicing to qualified service

personnel. Servicing is required when

the apparatus has been damaged in

any way, such as power-supply cord

or plug cord is damaged, liquid has

been spilled or objects have fallen

into the apparatus, the apparatus has

been exposed to rain or moisture,

does not operate normally, or has

been dropped.

AVIS:

NE PAS OUVRIR

Il ne se trouve a l’interieur aucune piece pourvant entre reparée l’usager.

SEE OWNERS MANUAL. VOIR CAHIER D’INSTRUCTIONS.

S’adresser a un reparateur compétent.

RISQUE DE CHOC ELECTRIQUE

No user serviceable parts inside. Refer servicing to qualified service personnel.

CAUTION

WARNING:

TO REDUCE THE RISK OF FIRE OR

ELECTRIC SHOCK DO NOT EXPOSE

THIS EQUIPMENT TO RAIN OR MOISTURE

DO NOT OPEN

RISK OF ELECTRIC SHOCK

The lightning flash with arrowhead

symbol within an equilateral triangle is

intended to alert the user of the pres-

ence of uninsulated “dangerous voltage”

within the product’s enclosure that may

be of sufficient magnitude to constitute

a risk of electric shock to persons. The

exclamation point within an equilateral

triangle is intended to alert the user of

the presence of important operating and

maintenance (servicing) instructions in

the literature accompanying the product

(i.e. this Quick Start Guide).

CAUTION To prevent electric shock,

do not use the polarized plug supplied

with the unit with any extension cord,

receptacle, or other outlet unless the

prongs can be fully inserted.

Power Source. AirTools™ Control

I/O hardware uses a switching power

supply that automatically adjusts to the

applied voltage. Ensure that your AC

mains voltage is somewhere between

100-240 VAC, 50-60 Hz. Use only the

power cord and connector specified for

the product and your operating locale.

A protective ground connection, by way

of the grounding conductor in the power

cord, is essential for safe operation.

User Serviceable Parts. There

are no user serviceable parts inside

the AirTools™ Control I/O. In case

of failure, customers inside the U.S.

should refer all servicing to the Syme-

trix factory. Customers outside the U.S.

should refer all servicing to an autho-

rized AirTools distributor. Distributor

contact information is available online at

www.airtoolsaudio.com.

Before You Begin