Symmons Industries, Inc. ■31 Brooks Drive ■Braintree, MA 02184 ■Phone: (800) 796-6667 ■ Fax: (800) 961-9621

Copyright

©

2019

Symmons

Industries,

Inc.

■symmons.com ■[email protected] ■ZV

-3292

REV

0

■ 031919

Problem Cause Solution

Diverter valve will not divert water.

Foreign matter in water supply may

cause blockages in plumbing lines and

the diverter valve cartridge.

Remove cartridge from diverter valve.

Flush lines free of foreign matter.

Inspect cartridge for debris. Replace

cartridge if necessary.

Water is leaking from the face of the

diverter valve.

Cap assembly is not fully sealed to

diverter valve.

Remove cap assembly. Inspect

threads for debris. Reinstall cap

assembly to diverter valve at

75

±

5

lbf-in of torque.

Diverter trim will not install to diverter

valve.

Diverter valve body rough-in is too

deep.

Use RTS-DIV-1EXT-NS to extend

diverter stem 1 inch.

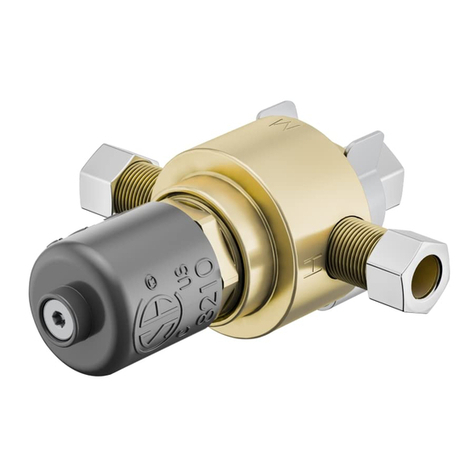

Maintenance (Cartridge Replacement)

2

A

C

D

E

1) Remove cap assembly (A) from

diverter valve by turning coun-

terclockwise. Remove cartridge

extender (C) and cartridge (D).

3) Orient new cartridge (D) with

arrow facing down. Align pegs on

cartridge (D) with indents inside

diverter valve (E).

DE

2)

Inspect cartridge for debris.

Replace cartridge if necessary.

4) Align spindle extender (C) with

broach on cartridge (D). Install

spindle extender (C) and cap

assembly (A) to cartridge (D).

Secure cap assembly (A) by

turning clockwise.

D

1

C

A

Notes:

1) Use caution not to dislodge

cartridge from valve body when

installing cap assembly (A).

2) Tighten cap assembly (A) to

75

±

5 lbf-in of torque.

Troubleshooting Chart

Note: Spacer (B) will be seated

inside cap assembly (A).

WARNING: This product can expose you to chemicals including lead, which is known to the state of California to cause cancer, birth defects, or

other reproductive harm. For more information, go to www.P65Warnings.ca.gov.