3

Installation

Symmons Industries, Inc. ■31 Brooks Drive ■Braintree, MA 02184 ■(800)796-6667 ■ Fax: (800)961-9621

©2014 Symmons Industries, Inc.

■

www.symmons.com

■

■

ZV-3010 REV D 05/27/14

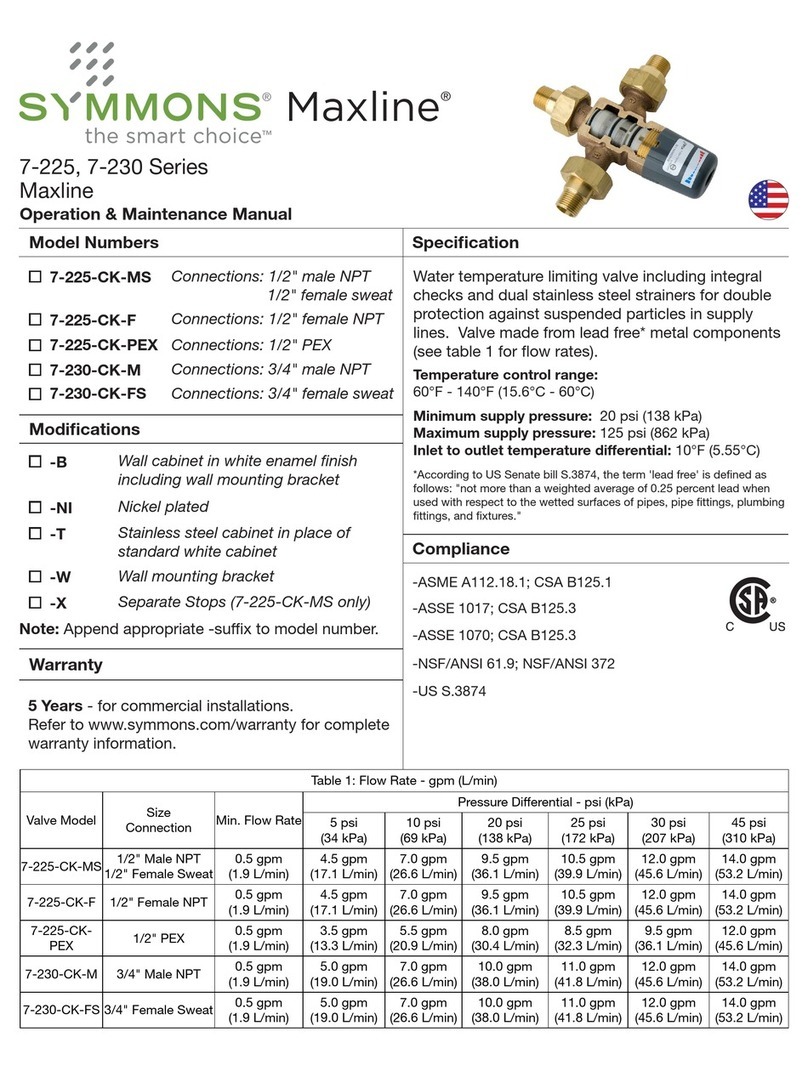

Sizing Valve

For assistance in sizing and selection of the proper

valve, consult your local representative or Symmons

Customer Service.

Installing Valve

1) Flush piping thoroughly prior to installing.

2) Install valve so as to allow clearance for replacing

cartridge. Valve can be installed in any orientation.

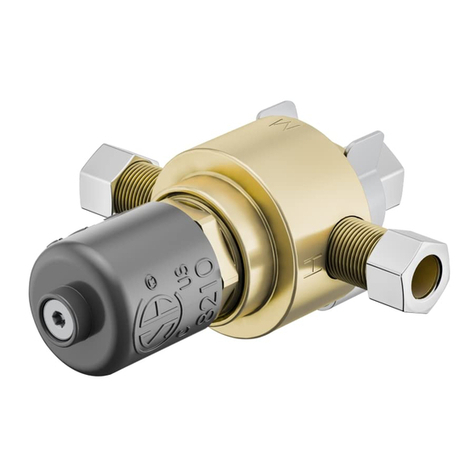

valve body

(shown without

valve fittings)

safety cap

retaining nut

cartridge

3-1/2"

(89 mm)

Valve

clearance

3) Connect valve input/ouput to supply ports.

a. Hot port marked (H)

b. Cold port marked (C)

c. Mixed output port marked (M)

Setting Valve Temperature

1) Turn hot and cold water supply on.

2) Open faucet to allow hot water to ow for a

minimum of one minute. For two handle faucets

turn on hot water only. For single handle faucets

turn on to the hot position.

3) Remove the safety cap by inserting a small at

tip screw driver into the wide slot at the base of

the cap and pry upward, then ip the safety cap

over 180 degrees and t onto the end of valve

spindle.

Temperature

Adjust

Safety Cap

4) Place thermometer in the outlet stream. Measure

and accurately set temperature. Inlet temperature

must be ± 10°F (5.55°C) of desired output.

5) To increase temperature turn safety cap

counter-clockwise. To decrease temperature turn

safety cap clockwise.

For single temperature applications adjust valve

outlet temperature with full ow of tempered

water from tting.

For dual temperature applications open

approximately 50% of all faucets to their full hot

position to ensure proper operating temperature

at peak demand.

6) Remove safety cap from end of valve spindle and

ip over 180 degrees, then press cap down and

snap back onto valve body to replace.

Note: Once the safety cap is snapped onto the

valve body the outlet temperature cannot be

changed without repeating steps 2-6.

Warning: Water temperatures in excess of

110°F (43°C) may cause scalding, or

severe injury!

Maxline

Operation & Maintenance Manual

7-210-CK