1 I56-6648-002

7/28/2020

GENERAL DESCRIPTION

The L-Series low frequency series of notification appliances offers a range

of low frequency sounder and low frequency sounder/strobe products for

wall and ceiling applications. Studies have shown that low frequency audible

devices that operate around 520Hz are more effective in waking individuals

in sleeping areas. These products are electrically backward compatible with

the previous generation of SpectrAlert Advance notification appliances. The

2-wire products fit systems where a single NAC controls both sounder and

strobe. The System Sensor MDL3 module may be used to provide synchroni-

zation for strobes and sounder strobes configured for Temp 3 tone.

Sounder-only models are approved for wall and ceiling installations.

FIRE ALARM SYSTEM CONSIDERATIONS

The National Fire Alarm Code, NFPA 72, requires that all sounders, used for

building evacuation produce temporal coded signals. Signals other than those

used for evacuation purposes do not have to produce the temporal coded sig-

nal. The National Fire Alarm Code, NFPA 72, requires that audible appliances

installed in sleeping areas produce a low frequency alarm signal that shall

be a square wave or provide equivalent awakening ability (effective Jan. 1,

2014). System Sensor recommends spacing notification appliances in compli-

ance with NFPA 72.

LOOP DESIGN AND WIRING

The system designer must make sure that the total current drawn by the de-

vices on the loop does not exceed the current capability of the panel supply,

and that the last device on the circuit is operated within its rated voltage. The

current draw information for making these calculations can be found in the

tables within this manual. For convenience and accuracy, use the voltage drop

calculator on the Tools menu of the System Sensor website.

When calculating the voltage available to the last device, it is necessary to

consider the voltage drop due to the resistance of the wire. The thicker the

wire, the smaller the voltage drop. Wire resistance tables can be obtained

from electrical handbooks. Note that if Class A wiring is installed, the wire

length may be up to twice as long as it would be for circuits that are not fault

tolerant.

NOTE: The total number of strobes on a single NAC must not exceed 69 for

24 volt applications. Loop resistance on a single NAC should not exceed 120

ohms for 24 volt.

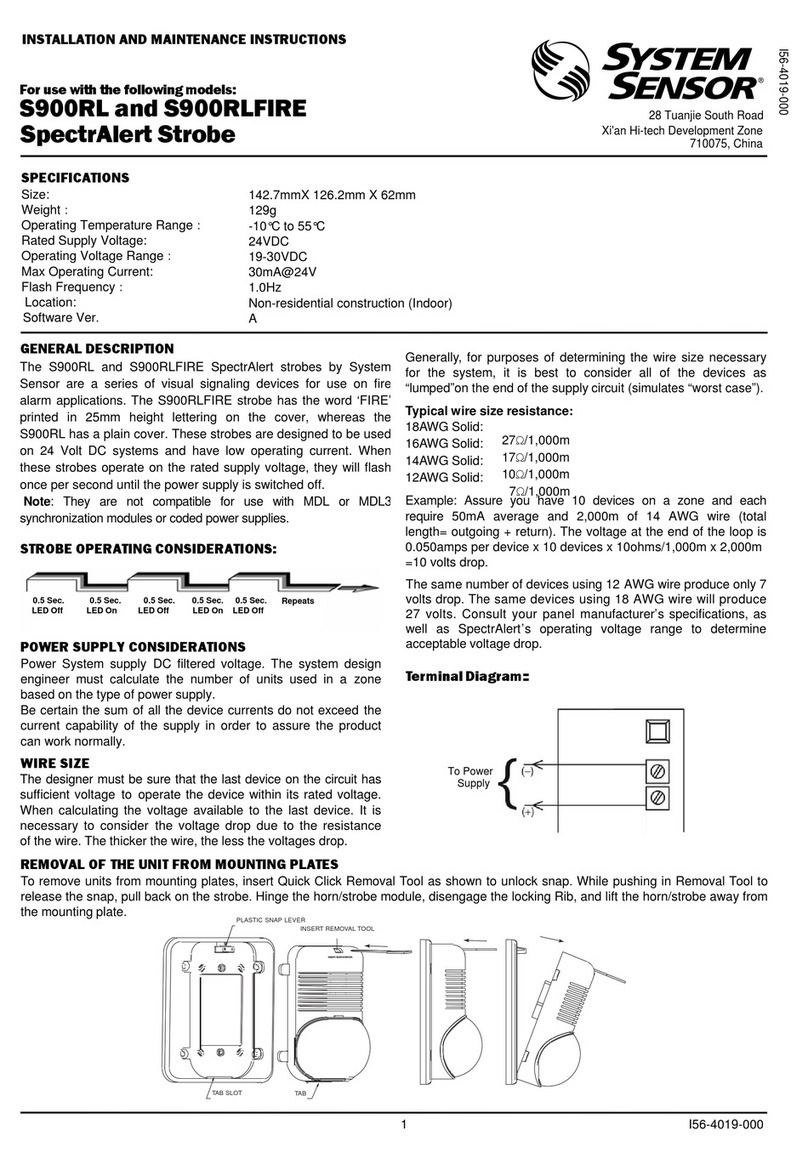

NOTE: A shorting spring is provided between terminals 2 and 3 of the mount-

ing plate to enable wiring checks after the system has been wired, but prior

to installation of the final product. This spring will automatically disengage

when the product is installed, to enable supervision of the final system.

Removal of a notification device will result in an open circuit indication on

the NAC.

INSTALLATION AND MAINTENANCE INSTRUCTIONS

L-Series Low Frequency

Sounders, Strobes, and Sounder/Strobes

For use with the following models: P2RL-LF, P2WL-LF, HRL-LF, HWL-LF, HGRL-LF, HGWL-LF, HCRL-LF, HCWL-LF, PC2RL-LF, PC2WL-LF

PRODUCT SPECIFICATIONS

Operating Temperature: 32°F to 120°F (0°C to 49°C)

Humidity Range: 10 to 93% Non-condensing

Strobe Flash Rate: 1 flash per second

Nominal Voltage (Low Frequency Sounder): Regulated 24VDC/FWR

Nominal Voltage (Low Frequency Sounder/Strobe): Regulated 24VDC/FWR

Operating Voltage Range (includes fire alarm panels with built in sync): 16 to 33V (24V nominal)

Operating Voltage with MDL3 Sync Module: 16.5 to 33V (24V nominal)

Input terminal wire gauge: 12 to 18 AWG

DIMENSIONS FOR PRODUCTS AND ACCESSORIES

WALL PRODUCTS Length Width Depth

Standard Sounder

5.6" (143mm) 4.7" (119mm) 1.5" (38 mm)

Sounder Strobe

5.6” (143mm) 4.7” (119mm) 1.93" (49mm)

Compact Sounder

5.26" (133 mm) 3.46" (88 mm) 1.5" (38 mm)

Standard device with SBBRL/WL Surface Mount Back Box 5.7" (145 mm) 4.8"(120mm) 3.3" (84mm)

C

ompact device with

SBBGRL/WL Surface Mount Back Box

5.4" (137 mm) 3.6"(91mm) 3" (76mm)

NOTE: SBBRL/WL Surface Mount Back Box intended only for standard sounder and sounder strobe. SBBGRL/WL Surface

Mount Back Box intended for compact sounder.

CEILING PRODUCTS Diameter Depth

Sounder

6.83" (173.5mm) 1.4" (36mm)

Sounder Strobe

6.83" (173.5mm) 2.47" (62.7mm)

Device with SBBCRL/WL Surface Mount Back Box 6.92" (175.8mm) 3.9" (99mm)

JUNCTION BOX OPTIONS

Standard Indoor Products: 4" x 4" x 1½", Single Gang, Double Gang, 4" Octagon, SBBRL/WL (wall), SBBCRL/WL (ceiling)

Compact Indoor Products: Single Gang, SBBGRL/WL (wall)

NOTICE: This manual shall be left with the owner/user of this equipment.

3825 Ohio Avenue, St. Charles, Illinois 60174

800/736-7672, FAX: 630/377-6495

www.systemsensor.com

I56-6648-002