D690-06-00 4 I56-2961-000R

©2006 System Sensor

The directional sounder will not work without power. The directional sounder gets

its power from the fire/security panel monitoring the alarm system. If power is cut off

for any reason, the directional sounder will not provide the desired audio warning.

The directional sounder may not be heard. The directional sounder may not be

heard if it is placed on a different floor from the person in hazard or if placed too far

away to be heard over the ambient noise such as traffic, air conditioners, machinery

or music appliances that may prevent alert persons from hearing the sounder. The

Sounder may not be heard by persons who are hearing impaired.

The Limitations of Directional Sounders

System Sensor warrants its enclosed product to be free from defects in

materials and workmanship under normal use and service for a period

of three years from date of manufacture. System Sensor makes no other

express warranty for the enclosed product. No agent, representative,

dealer, or employee of the Company has the authority to increase or alter

the obligations or limitations of this Warranty. The Company’s obliga-

tion of this Warranty shall be limited to the replacement of any part of

the product which is found to be defective in materials or workman-

ship under normal use and service during the three year period com-

mencing with the date of manufacture. After phoning System Sensor’s

toll free number 800-SENSOR2 (736-7672) for a Return Authorization

number, send defective units postage prepaid to: System Sensor, Returns

FCC Statement

NOTE: Directional Sounder has been tested and found to comply with the limits for a

Class A digital device pursuant to part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the in-

struction manual, may cause harmful interference to radio communications. Operation

of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

Three-Year Limited Warranty

Department, RA #__________, 3825 Ohio Avenue, St. Charles, IL 60174.

Please include a note describing the malfunction and suspected cause

of failure. The Company shall not be obligated to replace units which

are found to be defective because of damage, unreasonable use, modi-

fications, or alterations occurring after the date of manufacture. In no

case shall the Company be liable for any consequential or incidental

damages for breach of this or any other Warranty, expressed or implied

whatsoever, even if the loss or damage is caused by the Company’s

negligence or fault. Some states do not allow the exclusion or limita-

tion of incidental or consequential damages, so the above limitation or

exclusion may not apply to you. This Warranty gives you specific legal

rights, and you may also have other rights which vary from state to state.

Please refer to insert for the Limitations of Fire Alarm Systems

Figure 4.

BREAK WIRE AS SHOWN FOR

SUPERVISION OF CONNECTION.

DO NOT ALLOW STRIPPED WIRE

LEADS TO EXTEND BEYOND SWITCH

HOUSING. DO NOT LOOP WIRES.

A0337-00

The sounder has a set of input terminals to provide addi-

tional control of the sound output of the directional sounder.

These terminals can be connected to the dry relay contacts

of control devices such as heat sensors or control modules.

When the input is active it will disable the sound output of

the Sounder. Connect the disable function as shown in Fig-

ure 5. Refer to Table 3 for function switch settings.

Figure 5.

– VDC

TO NEXT DEVICE

OR EOL

OPTIONAL DISABLE CONTACT

+ VDC

Mechanical

Two screws are included for attaching the sounder to the

electrical junction box.

NOTE: If surface mounting is required, an extension ring

will be necessary to give proper depth for mounting the

sounder. The minimum depth required, in the backbox/

extension ring combination, is 21/4˝. Any combination of

4˝ × 4˝ backbox and 4˝ × 4˝ extension ring that gives an

interior depth of at least 21/4˝ may be used.

Mounting

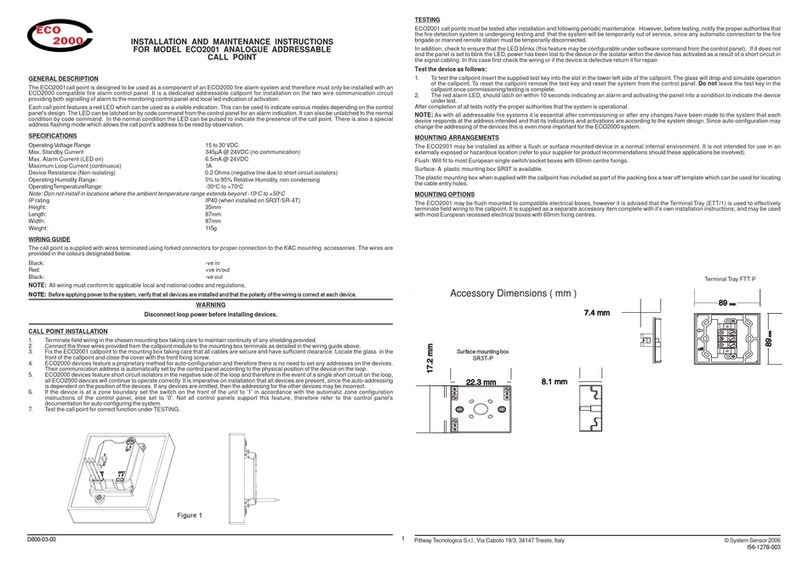

See Figure 6. The sounder can be flush mounted on a

4˝ × 4˝ × 21/4˝ back box, as follows:

A. Use the two 8-32 × 13/4˝ screws (provided) to attach

the Sounder to the back box.

B. Plug the remaining two holes that will not be used

for attachment with the plugs provided.

Figure 6.

4" x 4" x 2-1/4"

BACKBOX

PF24V

8-32

SCREWS

FILL

PLUGS

Skirt, BBS-SP201W

A0359-00

A0929-00

4" x 4" x 2-1/4"

BACKBOX

PF24V

8-32

SCREWS

FILL

PLUGS

A0176-05