2 I56-305-07

© System Sensor 1996

Three-Year Limited Warranty

System Sensor warrants its enclosed sounder/strobe to be free from de-

fects in materials and workmanship under normal use and service for a

period of three years from date of manufacture. System Sensor makes no

other express warranty for this sounder/strobe. No agent, representative,

dealer, or employee of the Company has the authority to increase or alter

the obligations or limitations of this Warranty. The Company’s obligation

of this Warranty shall be limited to the repair or replacement of any part of

the sounder/strobe which is found to be defective in materials or work-

manship under normal use and service during the three year period com-

mencing with the date of manufacture. After phoning System Sensor’s toll

free number 800-SENSOR2 (736-7672) for a Return Authorization number,

send defective units postage prepaid to: System Sensor, Repair Depart-

ment, RA #__________, 3825 Ohio Avenue, St. Charles, IL 60174. Please

include a note describing the malfunction and suspected cause of failure.

The Company shall not be obligated to repair or replace units which are

found to be defective because of damage, unreasonable use, modifica-

tions, or alterations occurring after the date of manufacture. In no case

shall the Company be liable for any consequential or incidental damages

for breach of this or any other Warranty, expressed or implied whatsoever,

even if the loss or damage is caused by the Company’s negligence or fault.

Some states do not allow the exclusion or limitation of incidental or conse-

quential damages, so the above limitation or exclusion may not apply to

you. This Warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

System Sensor’s sounder and signal strobe is designed to provide fire and

security hazard warning.

The strobe is for supplementary signaling use only.

The sounder or sounder/strobe combination will not work without

power. The sounder or sounder/strobe gets its power from the fire or se-

curity panel monitoring the alarm system. If power is cut off for any rea-

son, the sounder or sounder/strobe combination will not provide the

desired audible or visual warning.

The sounder may not be heard. The loudness of the sounder meets or

exceeds current Underwriters Laboratories’ standards. however, the

sounder may not alert a sound sleeper or one who has recently used drugs

or has been drinking alcoholic beverages. The sounder may not be heard if

it is placed in an area which is isolated by a closed door, or if it is located

on a different floor from the person in hazard or if placed too far away to

be heard over the ambient noise such as traffic, air conditioners, machin-

ery, or music appliances that may prevent alert persons from hearing the

alarm. The sounder may not be heard by persons who are hearing im-

paired.

The signal strobe may not be seen. The electronic visual warning signal

meets or exceeds current Underwriters Laboratories’ standard 1638. The

visual warning signal is suitable for direct viewing and must be installed

within an area where it can be seen by building occupants. The strobe

must not be installed in direct sunlight or areas of high light intensity

where the visual flash might be disregarded or not seen. The strobe may

not be seen by the visually impaired.

The signal strobe may cause seizures. Individuals who have a positive

photic response to visual stimuli with seizures, such as epileptics, should

avoid prolonged exposure to environments in which strobe signals, in-

cluding this strobe, are activated.

WARNING

The Limitations of Sounders and Strobes

Mounting

PA400 Sounders

1. The PA400 is intended for mounting to a standard 2-1/2"deep

single-gang box which allows sufficient clearance for conduit

entrance.

2. The PA400 is compatible with DC line supervision. The Piezo

Alert is polarized and has terminals marked with polarity. Ap-

ply positive supply voltage to the (+) terminal and negative

supply voltage to the (–) terminal. (See Figure 5.)

3. Mount the appliance to the electrical outlet box using the two

mounting screws supplied.

4. Field repair of the PA400 should not be attempted. Return to

factory for repair or replacement.

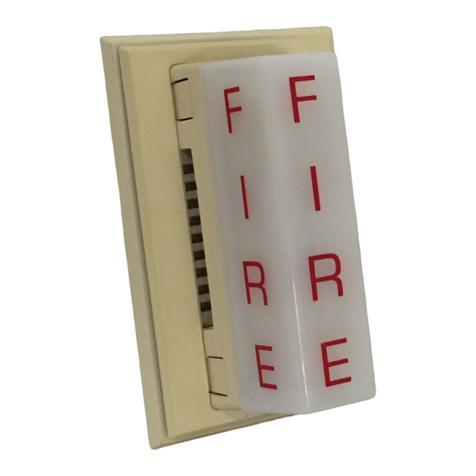

PS12 or PS24 Strobes

These optional strobes are interconnected to the PA400 by first re-

moving the two mounting screws from the sounder. Use a small

screwdriver to punch out the skinned-over areas as indicated in

Figure 6. Install the adapter plate on top of the sounder and screw

the combined sounder and adapter plate to the electrical outlet

box. Make sure field wiring terminals are oriented in the upward

position when mounted in the outlet box. Next, slide the strobe

directly into the slots in the plates. The positive solder lug may be

colored red or marked with a plus sign (+). This lug must be in

the slot closest to the field wiring terminals. Grasp the catch area

on each end of the strobe and squeeze while applying inward

force. Make sure the strobe catches fully engage the slots in the

adapter plate and that no gap appears at the interface between the

strobe and adapter plate.

From

control

panel

or

previous

device*

To

EOL

or

Next

Device

*NOTE: Shown with control panel in alarm. Panel polarity

reversed in supervisory condition. A78-1315-00.

A78-1778-00

Figure 6:

Figure 5:

A78-1314-01

Technical Manuals Online! - http://www.tech-man.com