OS & Y

VALVE

WATER

BY-PASS

VALVE

LOCAL ALARM

SHUT OFF

VALVE

RETARD

WATER

MOTOR

GONG

EPS10EXP

WET

SYSTEM

ALARM

CHECK

VALVE

OS & Y

VALVE

WATER

BY-PASS

VALVE

LOCAL ALARM

SHUT OFF

VALVE

RETARD

WATER

MOTOR

GONG

EPS10EXP

DRY

SYSTEM

ALARM

CHECK

VALVE

OS & Y

VALVE

WATER

BY-PASS

VALVE

LOCAL ALARM

SHUT OFF

VALVE

WATER

MOTOR

GONG

CHECK

VALVE

EPS10

WET SYSTEM WET SYSTEM DRY SYSTEM

WIRE TO ALARM

INDICATING CIRCUIT

OF FIRE ALARM

CONTROL PANEL

INDICATING CIRCUIT

OF FIRE ALARM

CONTROL PANEL

INDICATING CIRCUIT

OF FIRE ALARM

CONTROL PANEL

TO

SPRINKLER

SYSTEM

TO

SPRINKLER

SYSTEM

TO

SPRINKLER

SYSTEM

FIGURE 2. TYPICAL PIPING DIAGRAM FOR EPS10-1, EPS10-2

W0171-01

FIGURE 3. SWITCH TERMINALS:

W0173-00

GROUND

SCREW

COM

B

A

TERMINALS

BREAK WIRE AS SHOWN FOR

SUPERVISION OF CONNECTION.

DO NOT ALLOW STRIPPED WIRE

LEADS TO EXTEND BEYOND

SWITCH HOUSING. DO NOT

SWITCH #1

SWITCH #2

SWITCH #2

LOCKING

SCREW

TERMINAL “A”

TERMINAL “B”

EPS10 EPS10

point setting by approximately 2.5 PSI. A reset differential of approximately 3

PSI is typical throughout the entire adjustment range of switch.

4. Retest the set point several times to ensure accuracy of setting.

5. Re-seat locking screw.

TABLE 2.

MODEL

FACTORY SETTINGS (PSI)

Fall

(Low Switch)

Approx.

Reset

Rise

(High Switch)

Approx.

Reset

EPS10-1 — — 4 – 8 3 PSI diff.

EPS10-2 — — 4 – 8 3 PSI diff.

NOTE: The sensor assembly is not field replaceable. Do not attempt to disassemble

these parts. If you have any questions, consult System Sensor. System Sen-

sor recommends careful consideration of the following factors when specify-

ing and installing Alarm Pressure Switches. Always refer to the Installation

and Maintenance Instruction for specific recommendations on individual

devices before installing the unit.

• Electrical ratings stated in literature and on nameplates should not be exceeded.

• Overload on switch can cause failure on the first cycle. Always wire devices

according to national and local electrical codes.

• Install units away from shock and vibration. Proper electrical fittings should be

used to prevent moisture from entering the enclosure via the conduit.

• Test all devices for proper operation after initial installation. Perform preven-

tive maintenance and periodic testing as required by the applicable NFPA

standards but not less than bimonthly.

• Install a back-up control for all critical applications where control failure could

endanger life or property. A backup control to serve as a high or low limit

control is especially recommended for applications where a runaway condition

could result.

• Do not mount unit where ambient temperatures will exceed published limits.

• Avoid impact or mechanical loading.

System Sensor warrants its enclosed pressure switch to be free from defects in materials

and workmanship under normal use and service for a period of three years from date of

manufacture. System Sensor makes no other express warranty for this pressure switch.

No agent, representative, dealer, or employee of the Company has the authority to in-

crease or alter the obligations or limitations of this Warranty. The Company’s obligation

of this Warranty shall be limited to the repair or replacement of any part of the pressure

switch which is found to be defective in materials or workmanship under normal use

and service during the three year period commencing with the date of manufacture.

After phoning System Sensor’s toll free number 800-SENSOR2 (736-7672) for a Return

Authorization number, send defective units postage prepaid to: Honeywell, 12220 Rojas

Please refer to insert for the Limitations of Fire Alarm Systems

THREE-YEAR LIMITED WARRANTY

Drive, Suite 700, El Paso TX 79936, USA. Please include a note describing the malfunc-

tion and suspected cause of failure. The Company shall not be obligated to repair or

replace units which are found to be defective because of damage, unreasonable use,

modifications, or alterations occurring after the date of manufacture. In no case shall the

Company be liable for any consequential or incidental damages for breach of this or any

other Warranty, expressed or implied whatsoever, even if the loss or damage is caused by

the Company’s negligence or fault. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply

to you. This Warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

ADJUSTMENTS TO FACTORY SETTINGS

Both EPS10-1 and EPS10-2 devices are pre-adjusted at the factory to alarm at 4–8

PSI on rising pressure (see Table 2). Pressure switch settings may be adjusted in the

field to obtain a different pressure alarm response from 4 PSI to 20 PSI. The switch

has an override feature on the adjustment mechanism to prevent exceeding the 20

PSI max. setting of the switch. This override feature carries with it a tolerance band

that may limit the upper adjustment to 16–20 PSI. Care must be used when setting

the switch to ensure that the lower limit of 4 PSI is not exceeded. This will allow the

switch to reset within the 3 PSI differential stated.

1. Install pressure switch as stated in “INSTALLATION” portion of instruction

manual. Attach pressure test source to system.

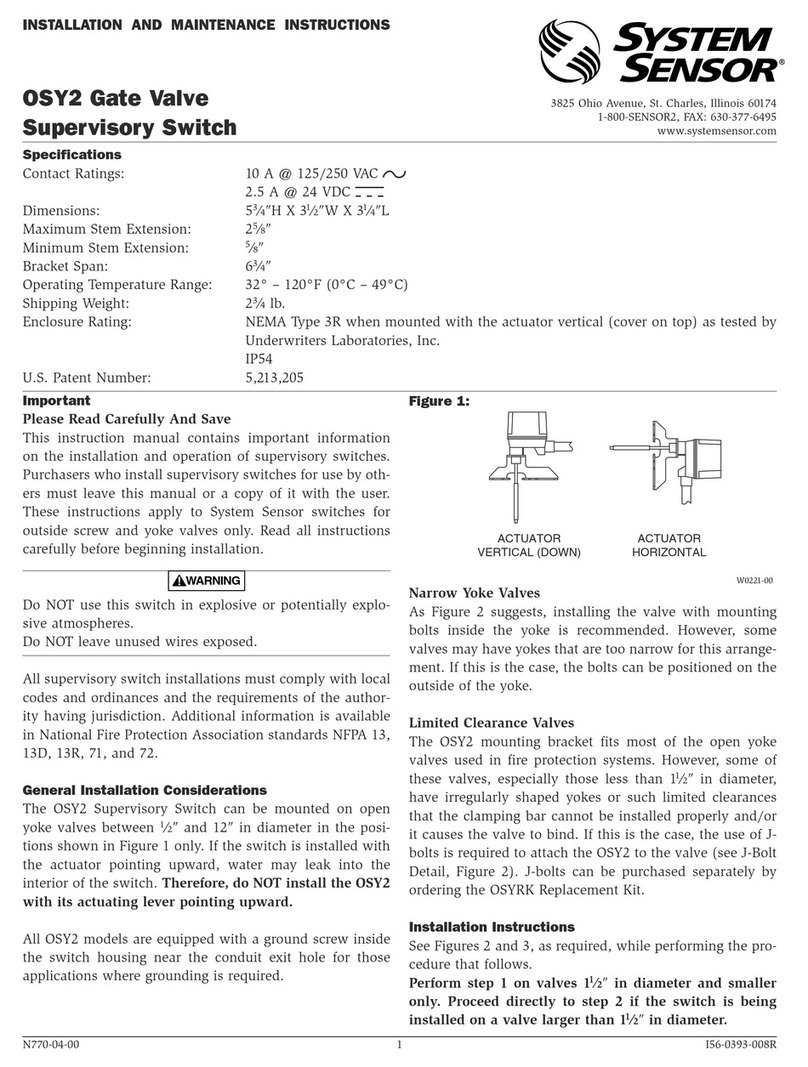

2. Back off locking screw (see Figure 1) to allow main adjustment wheel to rotate

freely.

3. Test trip point by slowly introducing pressure from the pressure test source.

When trip point is found, reduce pressure to zero. Rotate main adjustment

wheel (counterclockwise to increase pressure) and retest until switch trip point

is at the desired pressure setting (4–20 PSI range). Each number represents an

approximate trip point change of 0.2 PSI. One full rotation changes the trip

2 I56-0551-011R

©2016 System Sensor. 04-29