N770-04-00 3 I56-393-06

1. Remove and discard the two C-clips and roller from the

actuating lever.

2. Set the valve to its fully open position. Remove the OSY2

Supervisory Switch from the carton and adjust the posi-

tion of the retaining washers to provide sufficient bolt

length for the yoke thickness of the valve.

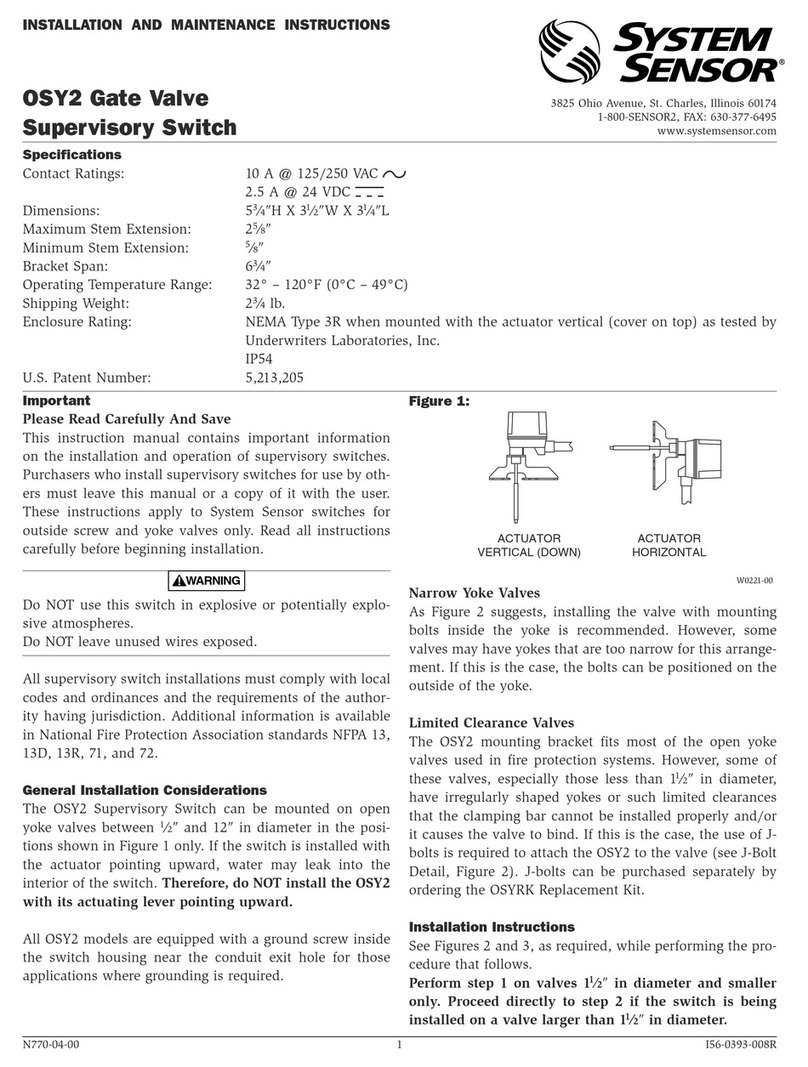

Position the switch on the valve with the bolts on the inside

(preferably) or outside of the yoke, depending on clear-

ances. Adjust the position of the OSY2 as far as possible

from the valve gland and in a location where the actuat-

ing lever contacts the unthreaded section of the valve

stem (if the valve stem is already grooved, proceed di-

rectly to step 6).

3. When the switch is in position on the valve, slide the

open end of the clamping bar onto the bolts and under

the retaining washers. If necessary, adjust the length of

the actuating lever by loosening the set screw on the

cam, sliding the lever in or out, as appropriate, and re-

tightening the set screw. The lever is properly adjusted

when it clears the clamping bar. Tighten the nuts by

hand and slide the OSY2 until the second switch trip

points are found as the lever rests on the valve stem.

This approximates the final position of the OSY2 after

the valve stem is grooved. Carefully check all clearances

of the bolts, actuator, mounting bracket, clamping bar,

and OSY2 cover. Adjust the position as necessary. If

clearance is a problem, refer to the Limited Clearance

Valves (page 1) section of this manual.

4. Mark the point on the valve stem where the actuating le-

ver contacts the valve stem.

5. Remove the OSY2 by loosening the nuts and sliding the

clamping bar from beneath the retaining washers. Re-

move the OSY2 from the valve and set it aside.

(a) Valves 11/2" in diameter and smaller only.

Use a 1/4" untapered round file to file a groove 3/32"

deep in the valve stem at the mark that was made in

step 4. Be sure to remove any burrs resulting from the

filing to avoid damaging the valve stem packing

gland.

(b) Valves larger than 11/2" inches in diameter only.

Use a 3/8" untapered round file to file a groove 1/8"

deep in the valve stem at the mark that was made in

step 4. Be sure to remove any burrs resulting from the

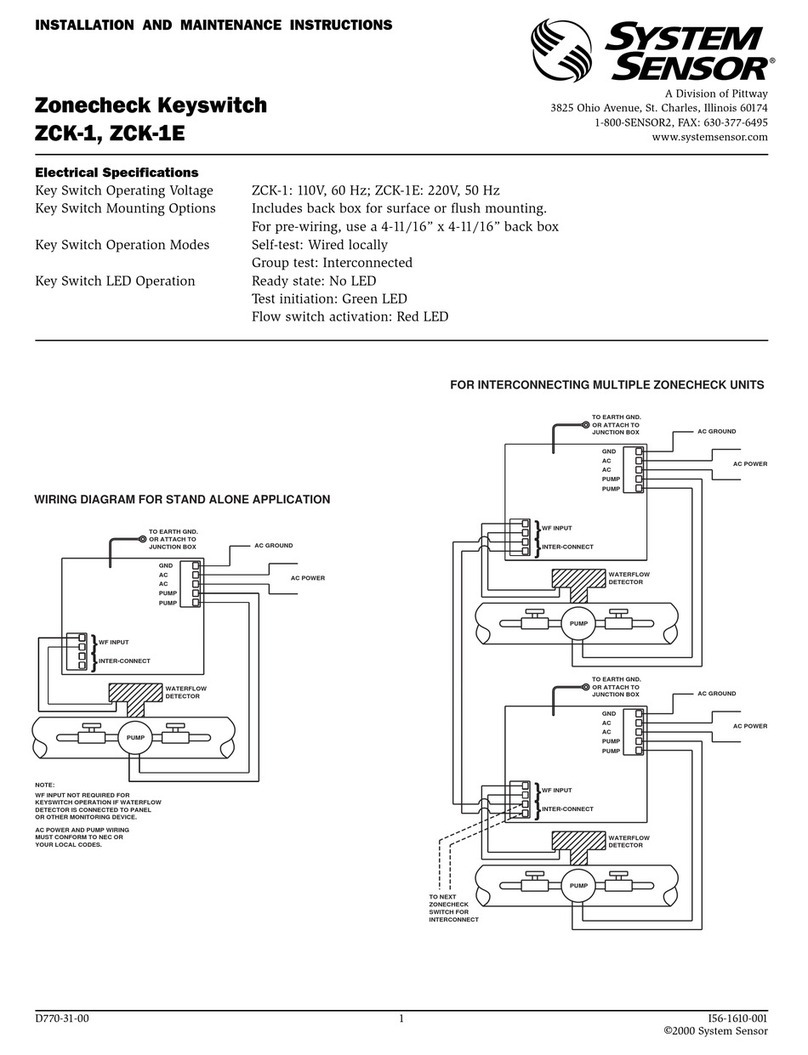

YOKE

GROOVE

CLAMPING BAR NOT SHOWN

THREADED VALVE

GLAND HEX NUT

OR BOLT

VALVE

STEM

GLAND

STEM HEX

Figure 3: filing to avoid damaging the valve stem packing

gland.

6. Mount the switch loosely with the actuating lever cen-

tered in the groove. When the switch is in position on

the valve, slide the open end of the clamping bar onto

the bolts and under the retaining washers, as indicated

in Figure 2.

7. Ensure that the actuating lever does not hit the inside

of the cover or the clamping bar at any point in its

travel. If it does, adjust the length of the lever by loos-

ening the set screw, sliding the lever in or out, as

needed, and retightening the set screw.

8. Adjust the supervisory switch position on the valve so

that both switches are depressed (COM to B circuit

open) when the actuating lever is in the groove with

the valve in the full open position. The COM to B

circuit should close when the valve is closed 1/5of its

travel or 2 full turns of the handle, whichever is less.

The switch produces an audible “click” when it closes.

The switch closure can also be tested electrically by

using an ohmmeter to test for continuity between its

terminals.

9. Tighten the nuts securely with a wrench and check the

operation of the OSY2 as in step 8. If necessary, reposi-

tion the OSY2 and test it again.

10. Wire the supervisory switch as shown in Figure 4.

11. Replace the OSY2 cover and tighten the tamper-resistant

cover screws with the special wrench provided. Store

this wrench in a secure location.

12. Test the operation of the OSY2 by closing the valve the

1/5of its travel distance or two full turns, whichever is

less. The circuit between COM and B should indicate a

closure during this procedure. If it does not, readjust

the supervisory switch and actuator positions until the

switch closes when the valve is operated.

Testing

Test the operation of all supervisory switches before they

are placed into service and at least semiannually, or as re-

quired by the authority having jurisdiction.

NOTE: Notify the proper authorities that the supervisory

switch(es) is (are) undergoing maintenance and,

therefore, will be temporarily out of service. Dis-

able the system or zone undergoing testing to pre-

vent unwanted alarms.

Test the operation of the OSY2 by closing the valve the 1/5

of its total travel distance or two full turns, whichever is

less. A contact closure must occur during this procedure. If

it does not, readjust the supervisory switch and actuator

positions until the switch closes when the valve operated.

Technical Manuals Online! - http://www.tech-man.com