SECTION 2 – LOADING THE MACHINE WITH TAPE

1) PLUG THE POWER CORD (SEE FIGURE 2) INTO THE PROPER ELECTRICAL OUTLET,

MAKING SURE THE VOLTAGE OF THE OUTLET IS THE SAME AS THE VOLTAGE OF THE

MACHINE.

2) PLACE THE TAPE ON THE TAPE MANDREL SO THAT THE TAPE WHEN PULLED IS

COMING OFF THE TOP OF THE ROLL AND THE ADHESIVE SIDE IS DOWN (SEE FIGURE 2).

PLEASE NOTE THAT THE MODEL 6250 CAN RUN 2 ROLLS OF TAPE IF NEITHER EXCEEDS

MORE THAN 1” IN WIDTH.

3) PULL THE TAPE TOWARDS THE FRONT OF THE MACHINE AND PRESS IT ONTO THE

FEED ROLLERS (SEE FIGURE 1).

4) TURN THE MACHINE ON BY PRESSING THE ON/OFF SWITCH LOCATED ON THE BACK

OF THE MACHINE (SEE FIGURE 2).

5) PRESS THE TAPE FEED BUTTON (SEE FIGURE 3) UNTIL THE TAPE EXITS THE FRONT OF

THE MACHINE. IF THE TAPE FOLDS DOWN IN BETWEEN THE CUTTER AND THE

CUTTER HOUSING, USE A SMALL, DULL INSTRUMENT AND BRING THE TAPE OUT

STRAIGHT. KEEP FEEDING THE TAPE UNTIL AN END CAN BE HELD.

6) PRESS THE CUT BUTTON (SEE FIGURE 3) AND REMOVE THE CUT PIECE OF TAPE.

7) THE MACHINE IS NOW READY FOR USE.

SECTION 3 – USING THE MACHINE IN MANUALMODE

1) LOAD THE TAPE AND TURN ON THE MACHINE AS EXPLAINED IN SECTION 2 ABOVE.

2) TO FEED TAPE, PRESS THE TAPE FEED BUTTON (SEE FIGURE 3) UNTIL THE LENGTH OF

THE TAPE REQUIRED IS FED. PLEASE NOTE THAT YOU CAN FEED AN INFINITE LENGTH

OF TAPE.

3) ONCE TAPE IS FED TO THE DESIRED LENGTH, PRESS THE CUT BUTTON (SEE FIGURE 3),

AND THE TAPE WILL BE CUT.

4) REMOVE THE TAPE AND MACHINE IS READY FOR NEXT CYCLE.

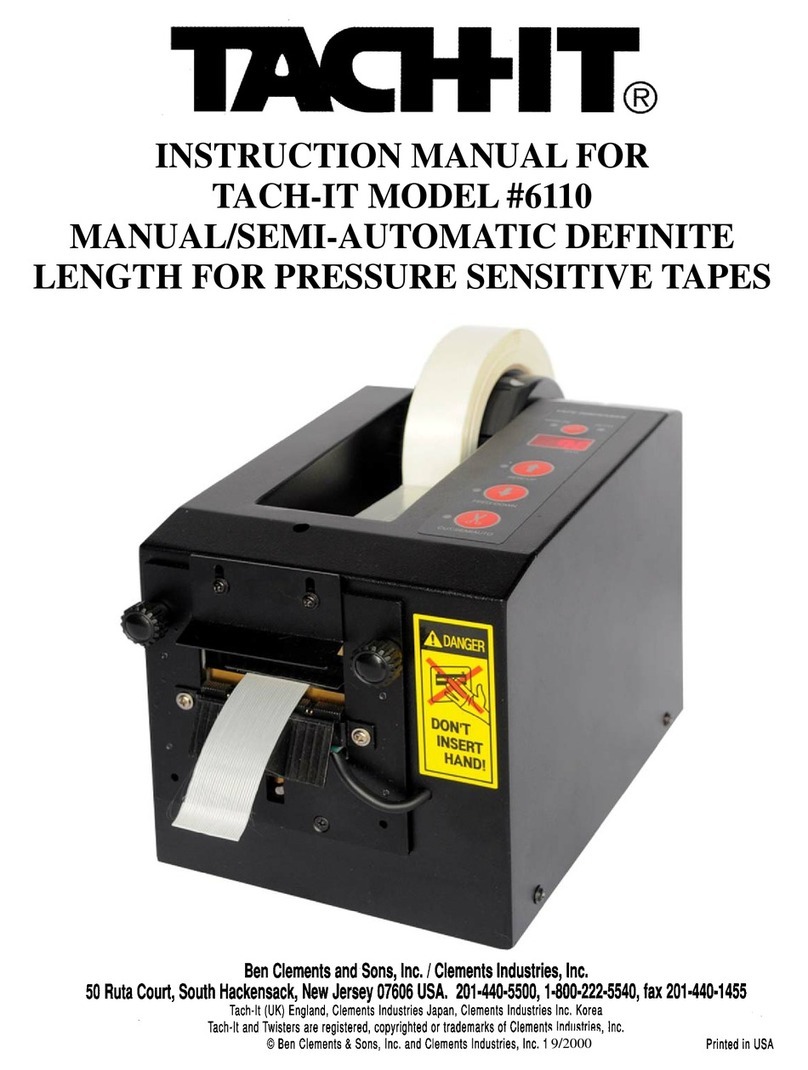

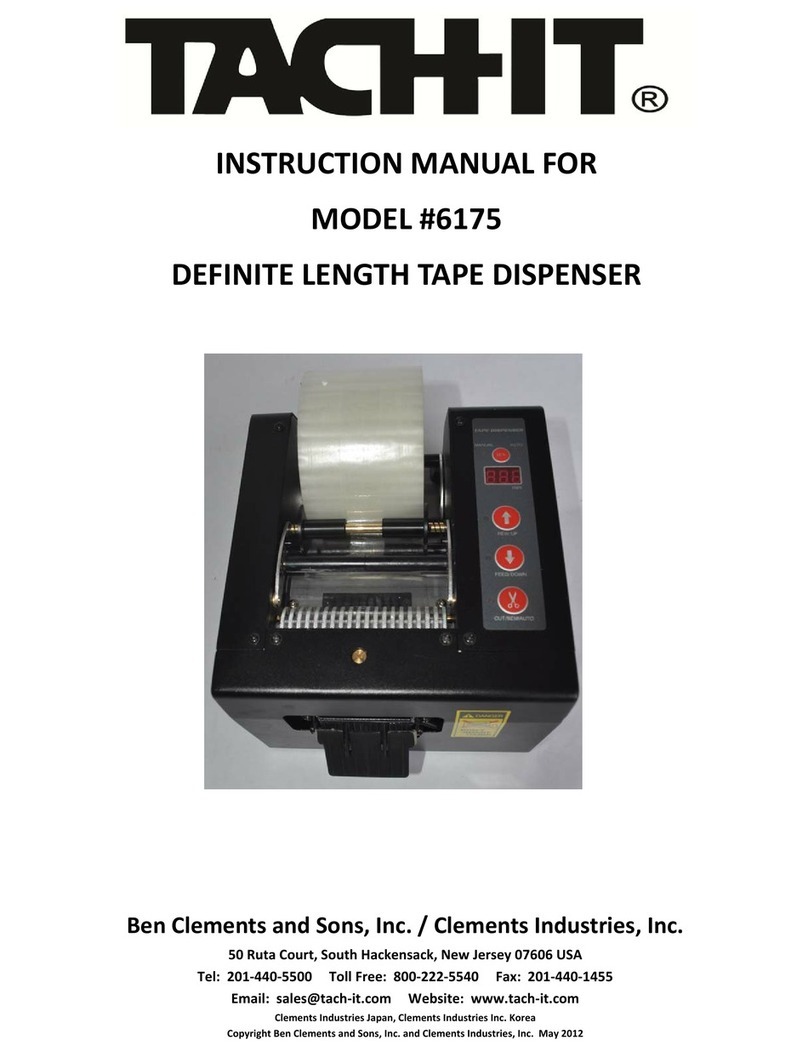

OVERVIEW OF PRODUCT:

THE TACH-IT MODEL #6250 IS A DEFINITE LENGTH TAPE DISPENSER THAT CREATES A 3/8”

TAB ON THE END OF THE TAPE AS IT IS BEING DISPENSED. ABLE TO WORK IN 3 MODES:

MANUAL MODE; THE OPERATOR HOLDS A FEED BUTTON UNTIL THE DESIRED LENGTH IS

REACHED AND THEN PRESSES A CUT BUTTON TO CUT THE TAPE, SEMI-AUTOMATIC MODE;

WHERE A LENGTH IS PROGRAMMED AND THE TAPE IS FED AND CUT, TO FEED ANOTHER

PIECE THE OPERATOR PRESSES THE CUT BUTTON, AUTOMATIC MODE; THE LENGTH IS PRO-

GRAMMED AND AS ONE PIECE OF TAPE IS FED, CUT AND REMOVED THE NEXT ONE FEEDS

OUT AUTOMATICALLY.