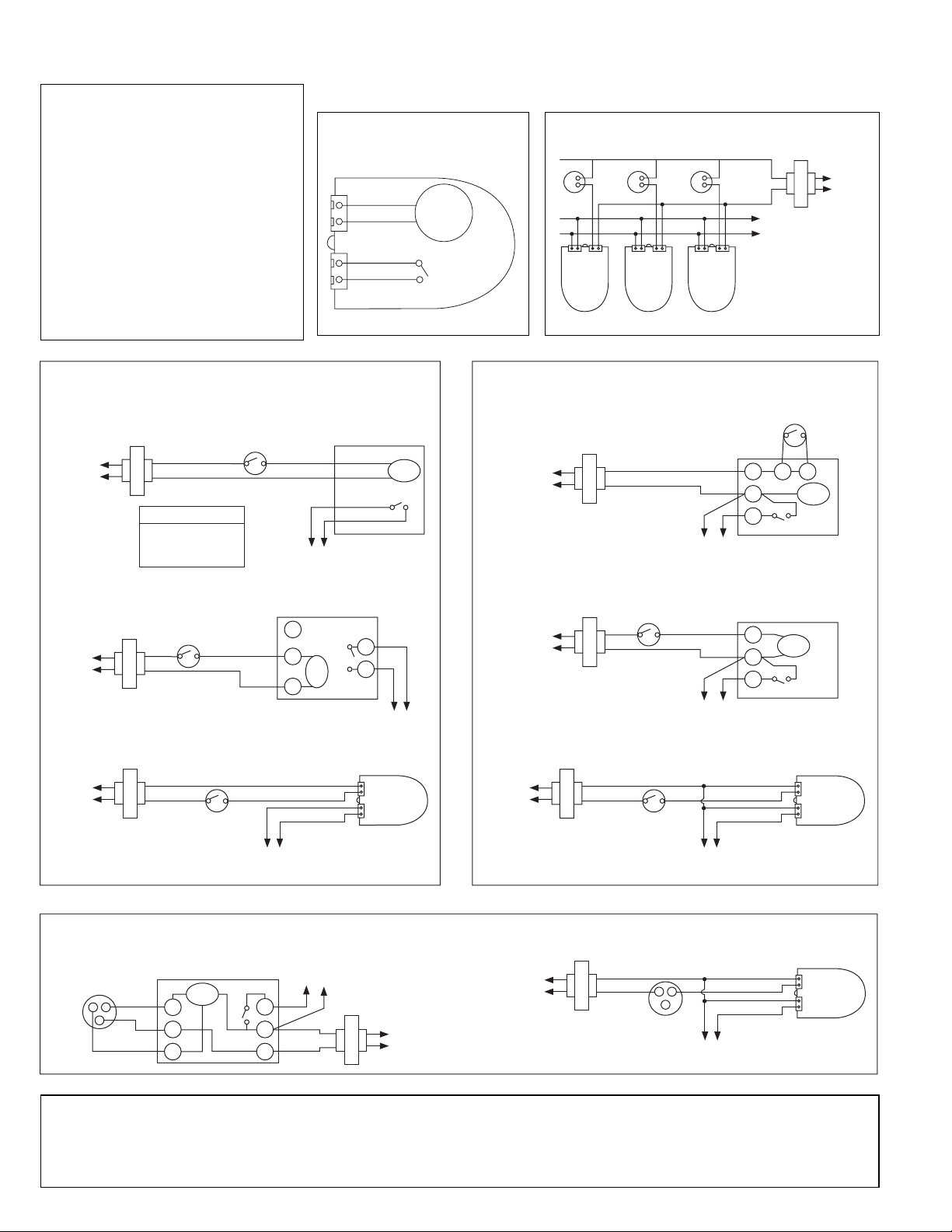

Application:

Taco Electronic Ball Valve (EBV) Zone Valves provide on-

off, normally open or normally closed control in closed

hot water systems. The valves can be used in a wide vari-

ety of heating applications, primarily designed for use

with fan coils, radiators, convectors, air handlers and

radiant applications. Refer to the Product Specifications

section for choosing the correct style valve for your

application.

The Energy Storage Principle:

The Taco Electronic Ball Valve (EBV) Zone Valve is a gear

driven, capacitor powered valve. EBV technology replaces

the typical spring (mechanical energy storage device) with

a Prostar Capacitor (electronic energy storage device) for

returning the valve to its normal position. In addition, we

have replaced the typical synchronous AC motor with a

high torque, high efficiency and highly reliable miniature

motor. All functions of the Zone Valve’s operation are

monitored on board by a powerful microprocessor. A non-

contact optical sensor (electronic eye) monitors the valve’s

position at all times. In the event of a loss of power to the

valve, the EBV has a built-in override button located on

the top of the operator for manual operation of the valve.

As soon as power is restored the valve automatically finds

it’s correct operating position, even if the ball has been

moved using the manual override.

Ease of Installation / Operation:

The EBV is the most technologically advanced zone

valve ever made. It’s also simple to install and operate.

The valve can be installed in any direction, in any ori-

entation. Based on the success of Taco 570 zone valve,

the EBV utilizes a dependable 1⁄4turn one-handed twist

lock for operator removal (see figure C). We then went a

step further, allowing the operator to be mounted to the

valve body in either direction (see figure A), great for

those tight baseboard jobs. Snap-in quick connects on

the back of the valve make for a secure and fast hook-up.

A green LED light shows full functionality of the valve’s

operation and thermostat status. As noted above, under

a no power situation the manual override button locat-

ed on the top of the valve allows the ball to be rotated to

any position and is also marked with an arrow to indi-

cate the position of the valve.

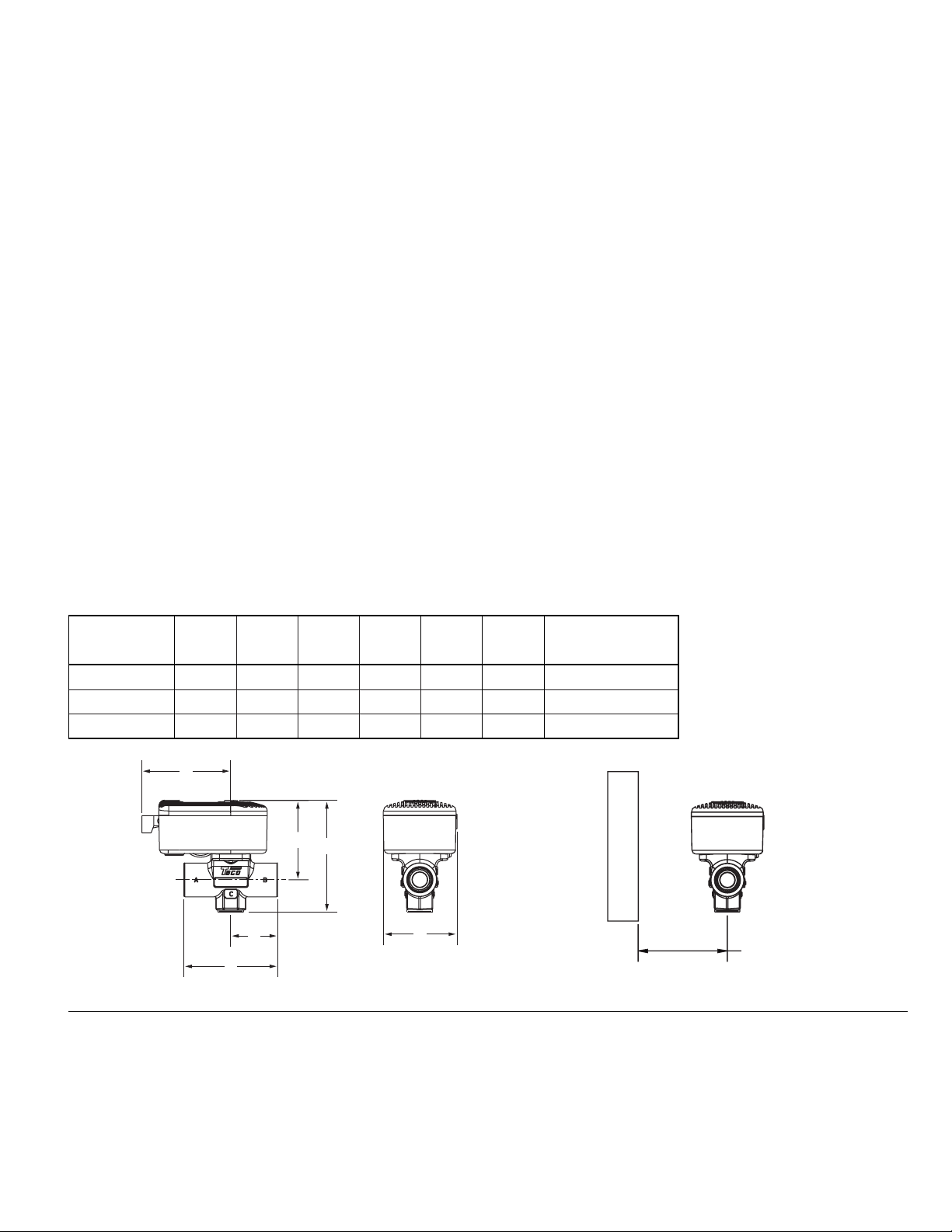

Valve Installation:

1. Valve body may be installed in any position, in

any orientation (see Figure A).

2. Before mounting body, refer to Figure B and

Dimensions Section for clearances.

3. Use of a solder with a melting point below 600°F

is recommended. Do not overheat! Make sure the

ball valve is in the FULL OPEN position during sol-

dering. Direct flame tip away from the center of

the valve. Cool valve quickly with a wet rag.

4. Solder build-up on the ball valve may prevent

proper opening and closing of the valve. Rotate

the manual operation button several times to

loosen any possible build-up.

5. Valve body can be submerged for leak testing

before the operator is attached.

Operator Installation / Wiring:

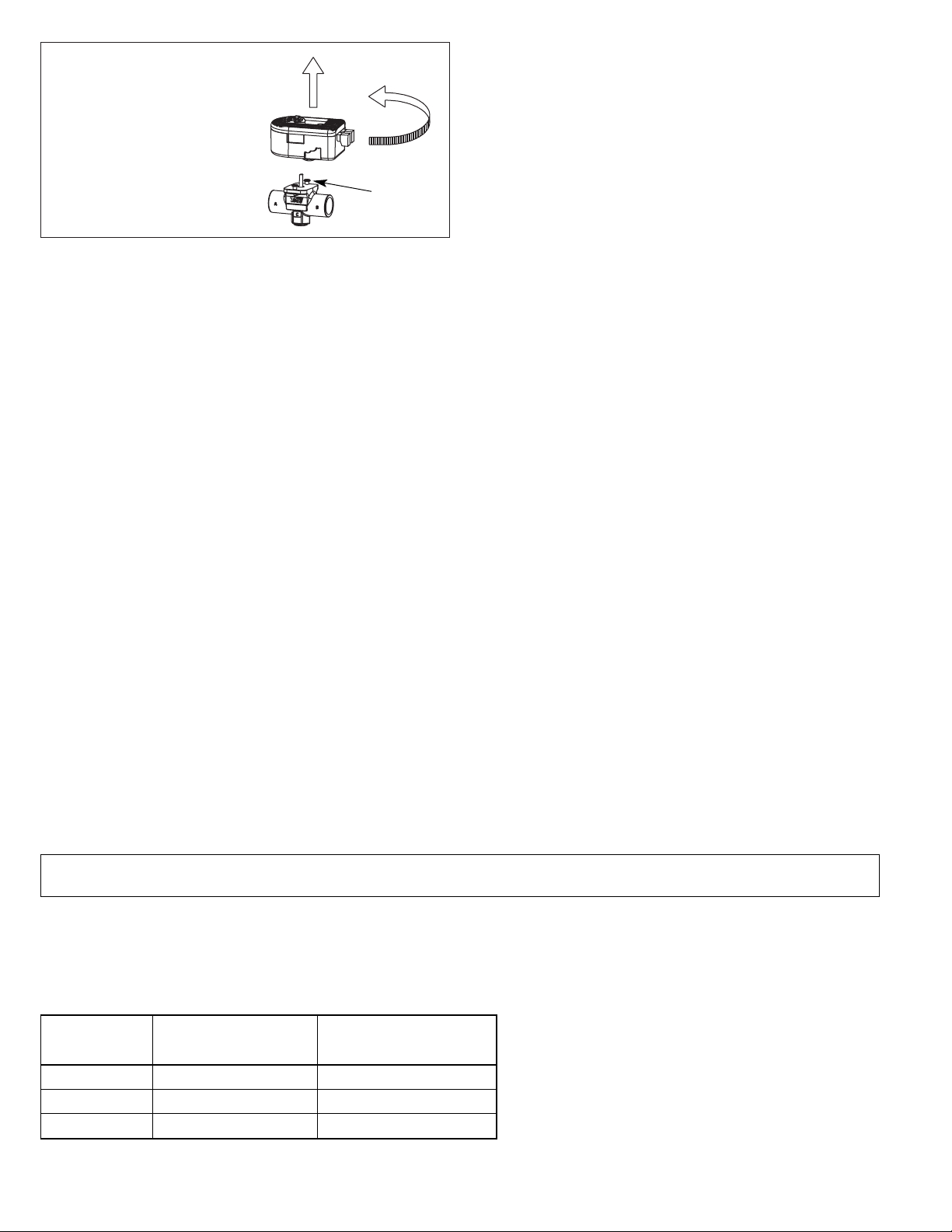

1. Valve operator may be attached to the valve body

in either direction (see Figure A).

2. Operator removal: Remove valve operator prior to

soldering by rotating the operator counterclock-

wise approximately 30 degrees and lifting upward

approximately 3⁄4” (see Figure C).

Instruction Sheet

Electronic Ball Valve (EBV) Zone Valve

102-111

SUPERSEDES: 102-111, Dated August 1, 2003 EFFECTIVE: June 1, 2006

Plant ID# 001-1011

WARNING: Operator must be removed

from the valve body before soldering.

Ball valve must be in the full open posi-

tion before soldering. Valve shipped in

the closed position.

Figure A

Two Position Head Placement.

Universal Body Placement.

May be installed in any position, any orientation.