© 2014 Taco Electronic Solutions, Inc. 1

Application Guide 505-009-2

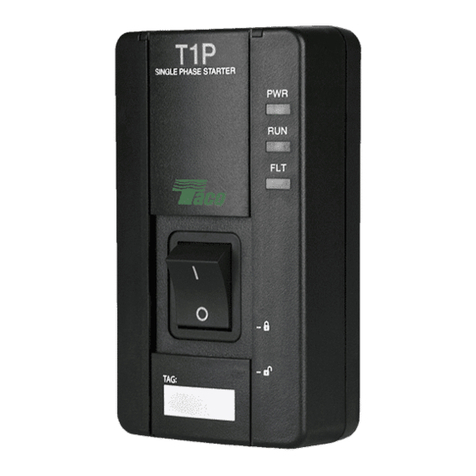

MPU2 Air Control – Pressure Dependent Multi-Zone

Self-Contained Interoperable Controller Model UCP-1

SUPERSEDES: January 16, 2013 EFFECTIVE: April 28, 2014

Table of Contents

MPU2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Purpose of This Guide . . . . . . . . . . . . . . . . . . . . . . . . . 3

Representations and Warranties . . . . . . . . . . . . . . . . . 4

Applicable Documentation . . . . . . . . . . . . . . . . . . . . . . 4

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 5

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Static Electricity . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

FCC Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Before Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About this Document . . . . . . . . . . . . . . . . . . . . . . . . 5

Inspecting the Equipment . . . . . . . . . . . . . . . . . . . . 5

What is Not Included with this Equipment . . . . . . . . 6

Equipment Location . . . . . . . . . . . . . . . . . . . . . . . . . 6

Selecting a Power Source . . . . . . . . . . . . . . . . . . . . 6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Mounting the Device . . . . . . . . . . . . . . . . . . . . . . . . 6

Routing Cabling to the Device . . . . . . . . . . . . . . . . . 7

Grounding the Device . . . . . . . . . . . . . . . . . . . . . . . 7

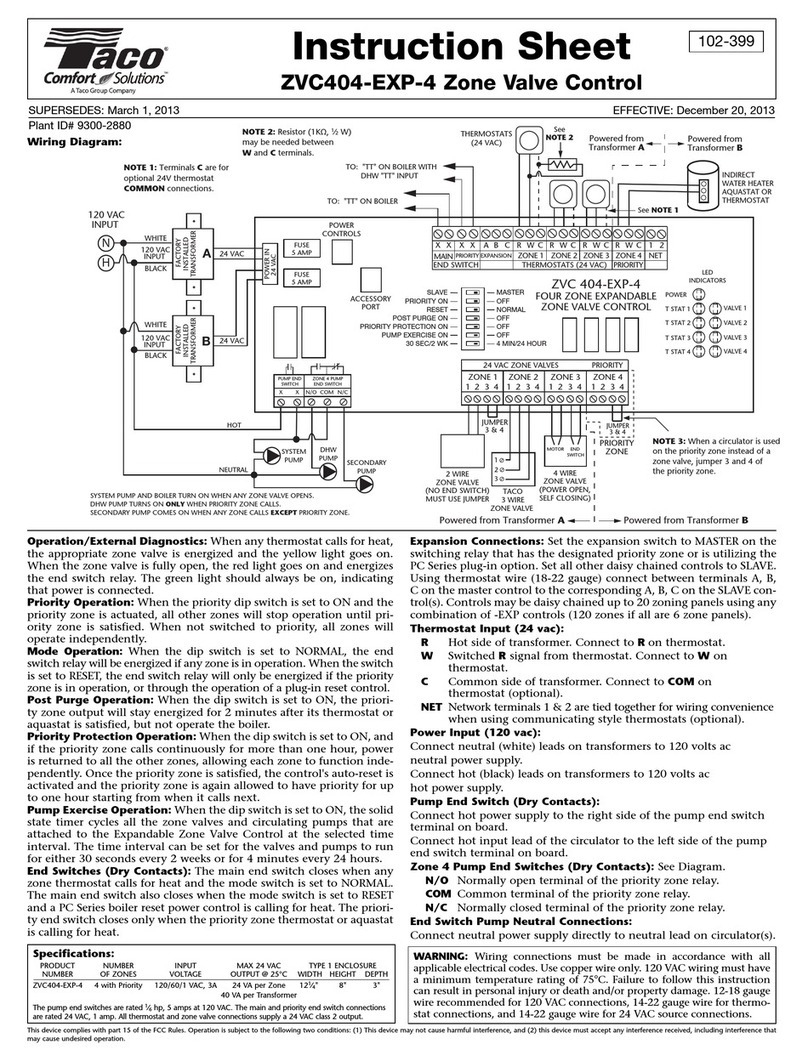

Wiring Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecting Input Devices . . . . . . . . . . . . . . . . . . . 10

Connecting Output Devices . . . . . . . . . . . . . . . . . . 11

Other Connections . . . . . . . . . . . . . . . . . . . . . . . . . 12

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mechanical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Application Description . . . . . . . . . . . . . . . . . . . . . . . . 15

Sequence of Operation. . . . . . . . . . . . . . . . . . . . . . . . 18

Operational Mode . . . . . . . . . . . . . . . . . . . . . . . . . 18

Occupancy Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Setpoint Calculations . . . . . . . . . . . . . . . . . . . . . . . 19

Supply Air Setpoint Reset Curve . . . . . . . . . . . . . . 19

Heating Sequence . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cooling Sequence . . . . . . . . . . . . . . . . . . . . . . . . . 24

Economizer Operation. . . . . . . . . . . . . . . . . . . . . . 27

Cutoff Temperatures . . . . . . . . . . . . . . . . . . . . . . . 28

Dehumidification . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Bypass Damper . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Fan Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Fan Proof. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

MPU2 and VAVD Communications . . . . . . . . . . . . 30

Associating VAVDs . . . . . . . . . . . . . . . . . . . . . . . . 30

Supply Air Temperature Monitoring . . . . . . . . . . . . 30

Indoor Air Quality. . . . . . . . . . . . . . . . . . . . . . . . . . 31

Smoke Detection . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Mixed Air Low Limit Detection . . . . . . . . . . . . . . . . 31

Filter Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Real Time Clock (RTC) . . . . . . . . . . . . . . . . . . . . . 32

Local Backup Schedule . . . . . . . . . . . . . . . . . . . . . 32

Runtime Accumulations. . . . . . . . . . . . . . . . . . . . . 32

Alarms and Events. . . . . . . . . . . . . . . . . . . . . . . . . 32

Automatic Configuration . . . . . . . . . . . . . . . . . . . . 33

Controller Identification . . . . . . . . . . . . . . . . . . . . . . . 33

Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Diagnostic LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Troubleshooting Tips . . . . . . . . . . . . . . . . . . . . . . . 42