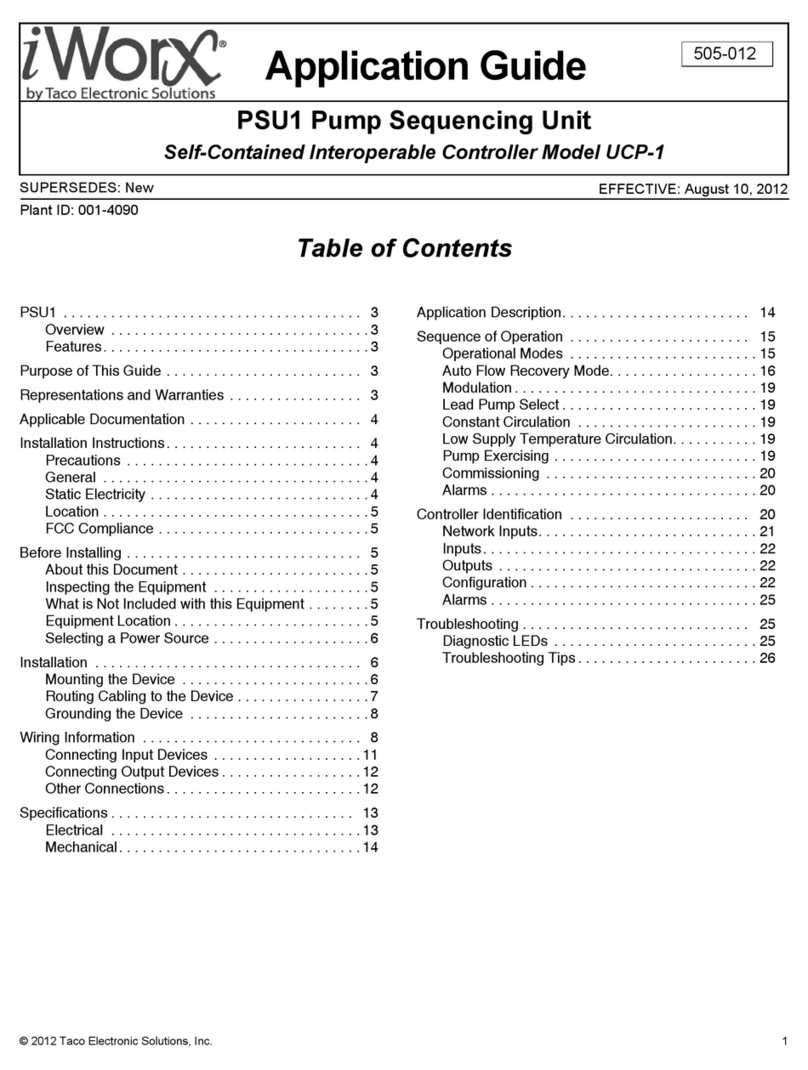

SLAVE

PRIORITY ON

RESET

POST PURGE ON

PRIORITY PROTECTION ON

PUMP EXERCISE ON

30 SEC/2 WK

MASTER

OFF

NORMAL

OFF

OFF

OFF

4 MIN/24 HOUR

Dip Switch Settings

Tr ublesh ting:

• Pr blem: Digital thermostats do not work cor-

rectly when connected to a zone valve control.

• S luti n: Some thermostats are a “Power

Stealing” type which means they are powered by

the zone control with just 2 wires (R& W). A

resistor may be needed in order to have the ther-

mostat work properly. This resistor should be

placed between the W& C(c mm n) terminals

of the zone control. If the thermostat manufac-

turer does not supply a resistor, a 1000 ohm ½

watt resistor has proven to work with most mod-

els and is readily available at electronic supply

outlets (e.g. Radio Shack). If the thermostat is bat-

tery powered, then check that the batteries are

fresh and installed correctly.

• Pr blem: No heat in a zone or room of build-

ing.

• S luti n: LED diagnostic lights will help find a

component that is not working properly. The

green LED should always be on, indicating that

power is connected and the fuse is good. When

there is a call for heat, the yellow LED will come

on indicating power to the zone valve. This

indicates the thermostat is working correctly.

When the zone valve fully opens and its end

switch makes contact, the red LED will come

on, the boiler turns on and a circulator will start

if connected to the zone control.

For information on Taco’s Zone

Valve Controls (ZVC) including

catalog sheet, instruction sheets,

Visio stencils and our highly

praised Zone Controls Wiring

Guide, scan the QR code to the

right or go to our website:

http://www.taco-hvac.com.

CONTROLS MADE EASY.®

TACO, INC., 1160 Cranston Str t, Cranston, RI 02920 T l phon : (401) 942-8000 FAX: (401) 942-2360.

TACO (Canada), Ltd., 8450 Lawson Road, Unit #3, Milton, Ontario L9T 0J8. T l phon : 905/564-9422. FAX: 905/564-9436.

Visit o r web site at: http://www.taco-hvac.com

Print d in USA

Copyright 2013

TACO, Inc.

Taco, Inc. will r pair or r plac without charg

(at th company’s option) any product or part

which is prov n d f ctiv und r normal us

within thr (3) y ars from th dat of start-up or

thr (3) y ars and six (6) months from dat of

shipm nt (which v r occurs first).

In ord r to obtain s rvic und r this warranty, it

is th r sponsibility of th purchas r to promptly

notify th local Taco stocking distributor or Taco

in writing and promptly d liv r th subj ct prod-

uct or part, d liv ry pr paid, to th stocking dis-

tributor. For assistanc on warranty r turns, th

purchas r may ith r contact th local Taco

stocking distributor or Taco. If th subj ct prod-

uct or part contains no d f ct as cov r d in this

warranty, th purchas r will b bill d for parts

and labor charg s in ff ct at tim of factory

xamination and r pair.

Any Taco product or part not install d or op rat-

d in conformity with Taco instructions or which

has b n subj ct to misus , misapplication, th

addition of p trol um-bas d fluids or c rtain

ch mical additiv s to th syst ms, or oth r

abus , will not b cov r d by this warranty.

If in doubt as to wh th r a particular substanc

is suitabl for us with a Taco product or part, or

for any application r strictions, consult th

applicabl Taco instruction sh ts or contact

Taco at [401-942-8000].

Taco r s rv s th right to provid r plac m nt

products and parts which ar substantially simi-

lar in d sign and functionally quival nt to th

d f ctiv product or part. Taco r s rv s th right

to mak chang s in d tails of d sign, construc-

tion, or arrang m nt of mat rials of its products

without notification.

TACO OFFERS THIS WARRANTY IN LIEU OF

ALL OTHER EXPRESS WARRANTIES. ANY

WARRANTY IMPLIED BY LAW INCLUDING

WARRANTIES OF MERCHANTABILITY OR FIT-

NESS IS IN EFFECT ONLY FOR THE DURATION

OF THE EXPRESS WARRANTY SET FORTH IN

THE FIRST PARAGRAPH ABOVE.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR STATU-

TORY, OR ANY OTHER WARRANTY OBLIGA-

TION ON THE PART OF TACO.

TACO WILL NOT BE LIABLE FOR ANY SPE-

CIAL, INCIDENTAL, INDIRECT OR CONSE-

QUENTIAL DAMAGES RESULTING FROM THE

USE OF ITS PRODUCTS OR ANY INCIDENTAL

COSTS OF REMOVING OR REPLACING

DEFECTIVE PRODUCTS.

This warranty giv s th purchas r sp cific

rights, and th purchas r may hav oth r rights

which vary from stat to stat . Som stat s do

not allow limitations on how long an impli d war-

ranty lasts or on th xclusion of incid ntal or

cons qu ntial damag s, so th s limitations or

xclusions may not apply to you.

LIMITED WARRANTY STATEMENT

Optional power stealing thermostat resistor part number: SRTR-001RP

(Value: 1000 Ohms, 1/2 watt or higher)

Replacement Zone Valve Controls fuses part number: SR5A-005RP

(Manufacture: Littlefuse, Part Number: 229005)

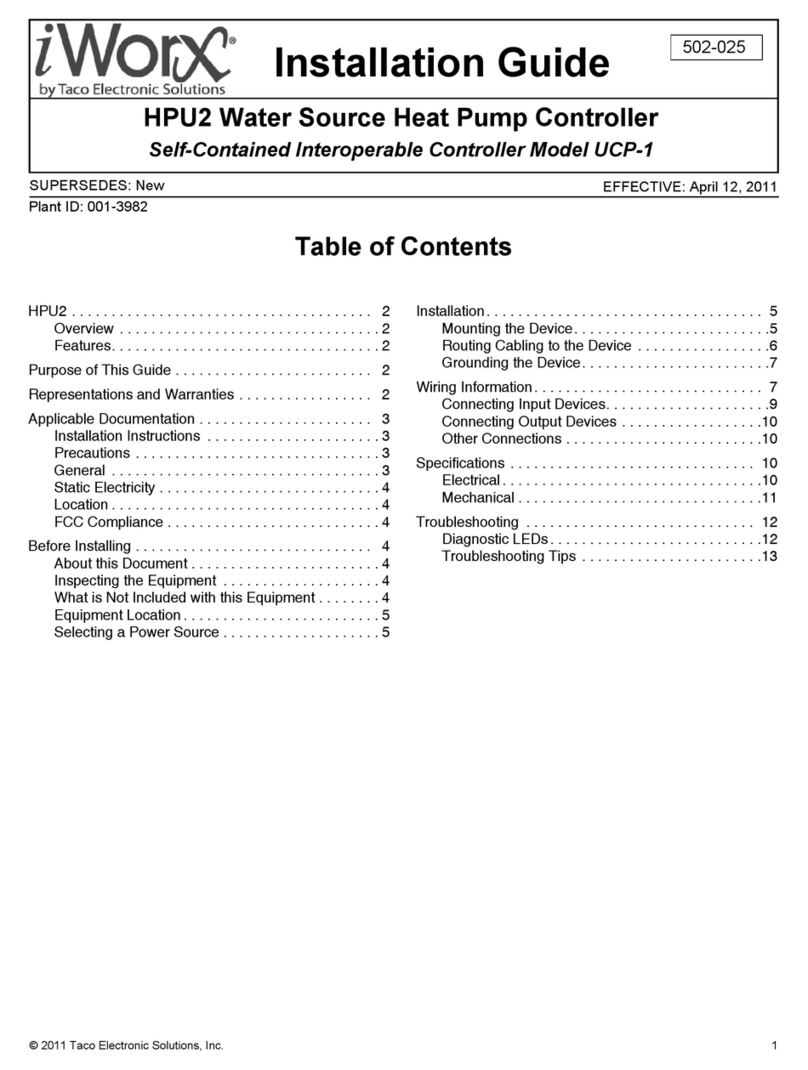

24 VAC

FACTORY

INSTALLED

TRANSFORMER

120 VAC

INPUT

WHITE

BLACK

H

N

BOILER

24 VAC

FACTORY

INSTALLED

TRANSFORMER

120 VAC

INPUT

WHITE

BLACK

24 VAC

FACTORY

INSTALLED

TRANSFORMER

120 VAC

INPUT

WHITE

BLACK

24 VAC

FACTORY

INSTALLED

TRANSFORMER

120 VAC

INPUT

WHITE

BLACK

Note: When a circulator is used on the

priority zone instead of a zone valve,

jumper 3 and 4 of the priority zone.

SWITCH SETTINGS

Master/Slave: Master

Reset/Normal: Normal

Priority Zone: On

SWITCH SETTINGS

Master/Slave: Slave

Reset/Normal: Normal

Priority Zone: Off

120 VAC

INPUT

MASTER

SLAVE

SYSTEM PUMP AND BOILER TURN ON

WHEN ANY ZONE VALVE OPENS.

SYSTEM

PUMP

DRY

CONTACTS

DRY

CONTACTS

TO: "TT" ON BOILER

TO: "TT" ON BOILER WITH

DHW "TT" INPUT

1234

ZONE 1

1234

ZONE 2

1234

ZONE 3

1234

ZONE 4

1234

ZONE 5

1234

ZONE 6

PRIORITY

ZONE

2 WIRE ZONE VALVE

(NO END SWITCH)

MUST USE JUMPER

TACO

3 WIRE

ZONE VALVE

1

2

3

JUMPER

3 & 4

MOTOR END

SWITCH

4 WIRE ZONE VALVE

(POWER OPEN,

SELF CLOSING)

JUMPER

3 & 4 SEE NOTE

ZVC 406-EXP-4

SIX ZONE EXPANDABLE

ZONE VALVE CONTROL

POWER IN

24 VAC

N/O COM N/C

ZONE 6 PUMP

END SWITCH

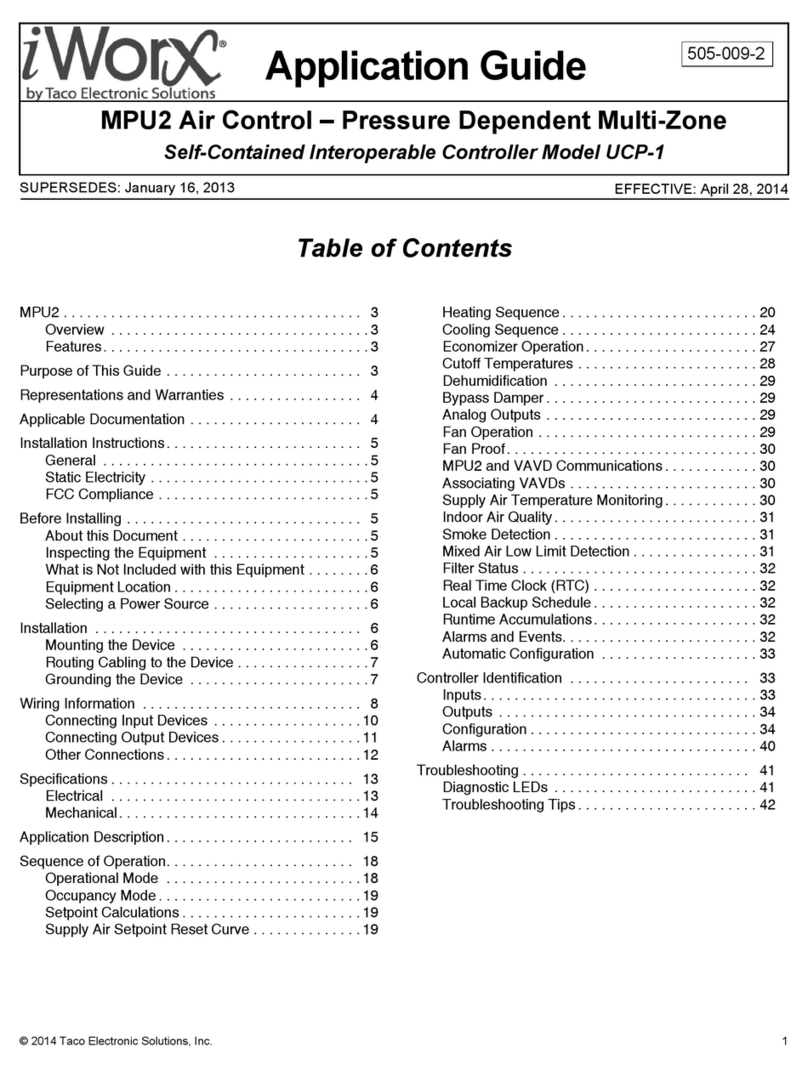

SLAVE

PRIORITY ON

RESET

POST PURGE ON

PRIORITY PROTECTION ON

PUMP EXERCISE ON

30 SEC/2 WK

MASTER

OFF

NORMAL

OFF

OFF

OFF

4 MIN/24 HOUR

THERMOSTATS

24 VAC

T STAT 1 VALVE 1

T STAT 2 VALVE 2

T STAT 3 VALVE 3

T STAT 4 VALVE 4

VALVE 5

T STAT 6 VALVE 6

POWER

LED

INDICATORS

T STAT 5

ZONE 1 ZONE 2

ZONE 3

ZONE 4 ZONE 5 ZONE 6 NET

EXPANSION

MAIN PRIORITY

X X X X A B C RWCRWCRWCRWCRWCRWC 1 2

END SWITCH THERMOSTATS (24 VAC) PRIORITY

24 VAC ZONE VALVES

1234

ZONE 1

1234

ZONE 2

1234

ZONE 3

1234

ZONE 4

1234

ZONE 5

1234

ZONE 6

PRIORITY

ZONE

2 WIRE ZONE VALVE

(NO END SWITCH)

MUST USE JUMPER

TACO

3 WIRE

ZONE VALVE

1

2

3

JUMPER

3 & 4

MOTOR END

SWITCH

4 WIRE ZONE VALVE

(POWER OPEN,

SELF CLOSING)

JUMPER

3 & 4 SEE NOTE

ZVC 406-EXP-4

SIX ZONE EXPANDABLE

ZONE VALVE CONTROL

POWER IN

24 VAC

N/O COM N/C

PUMP END

SWITCH

ZONE 6 PUMP

END SWITCH

SLAVE

PRIORITY ON

RESET

POST PURGE ON

PRIORITY PROTECTION ON

PUMP EXERCISE ON

30 SEC/2 WK

MASTER

OFF

NORMAL

OFF

OFF

OFF

4 MIN/24 HOUR

THERMOSTATS

24 VAC

INDIRECT

WATER HEATER

AQUASTAT OR

THERMOSTAT

T STAT 1 VALVE 1

T STAT 2 VALVE 2

T STAT 3 VALVE 3

T STAT 4 VALVE 4

VALVE 5

T STAT 6 VALVE 6

POWER

LED

INDICATORS

T STAT 5

ZONE 1 ZONE 2

ZONE 3

ZONE 4 ZONE 5 ZONE 6 NET

EXPANSION

MAIN PRIORITY

X X XX A B CRWCRWCRWCRWCRWCRWC 1 2

END SWITCH THERMOSTATS (24 VAC) PRIORITY

24 VAC ZONE VALVES

PRIORITY

PRIORITY

XX

PUMP END

SWITCH

XX

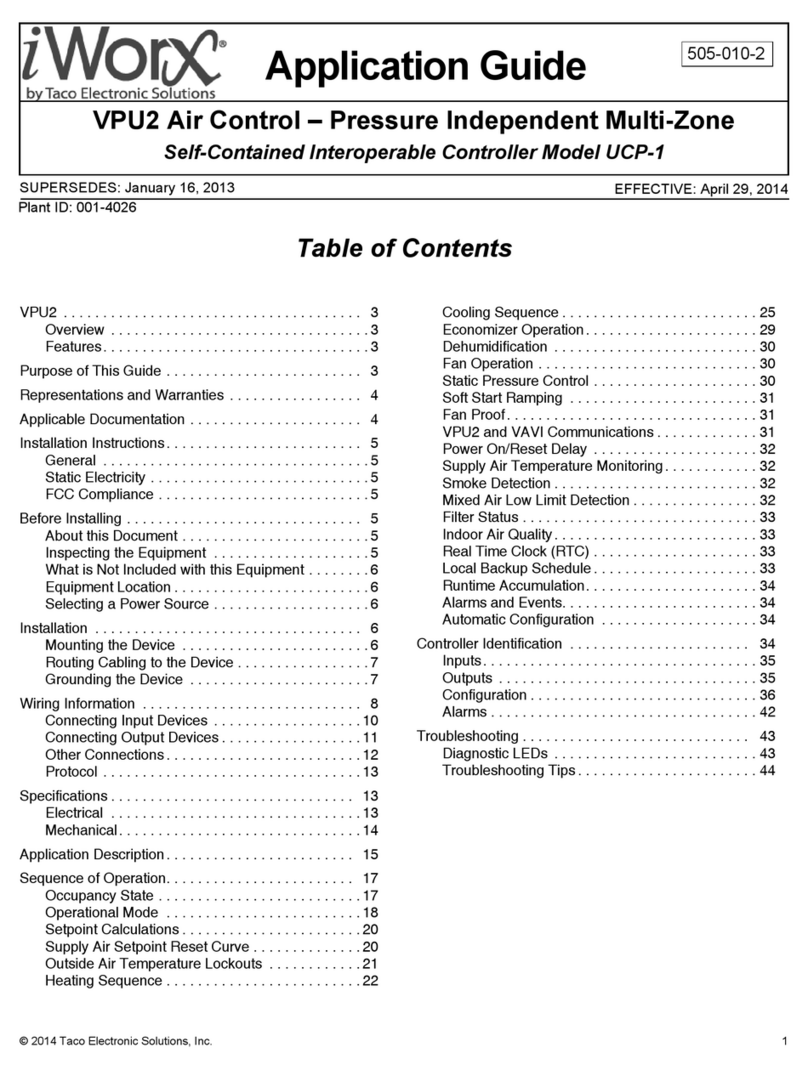

POWER

CONTROLS

ACCESSORY

PORT

FUSE

5 AMP

FUSE

5 AMP

POWER

CONTROLS

ACCESSORY

PORT

FUSE

5 AMP

FUSE

5 AMP

2 EXP Z ne Valve C ntr ls C nnected T gether

with System Pump