Printer Mechanism

The printer mechanism comprises a 384 element, thin film head and stepper motor driven transport. Battery voltage

and head temperature compensation is utilised to provide constant print quality across the range of operating

conditions.

Paper out: The printer will automatically detect when the printer paper has run out. The Status indicator will flash

(0.5 sec on 0.5 sec off) to denote that the paper has run out. Use the paper feed button to feed through the last few

centimetres of paper and fit a new roll as described on page 4.

Head thermal limit: After extensive printing the print head temperature may rise to an unusable level. If this occurs

the Status indicator will flash (0.25 sec on 0.5 sec off) and printing will be suspended until the head temperature

returns to normal levels.

Power Supply

Power is supplied to the printer from a 4.8V internal NiMHbattery pack or from the external mains adapter. The

mains adapter will trickle charge the batteries when the printer is turned on or off (charge time approx. 16 hours).

The Status indicator will light to show that the battery pack is nearly exhausted.

Power consumption Battery Pack

Sleep 130µA

Standby 40mA Capacity 600mAH

Running – Min 0.4A Charge current 50mA

Ave 1.3A Weight 100g

Max 2.8A Battery life Approx 10000 (30m) of continuous printing

Note: The peak current can reach a maximum of 4A

The MCP9810-112 should only be used in conjunction with an MPS101(UK), MPS102(EURO) or MPS103(US)

power adapter. Users wishing to provide their own power source must contact Martel.

The use of an unapproved source may void the printer’s warranty.

Power On Procedure

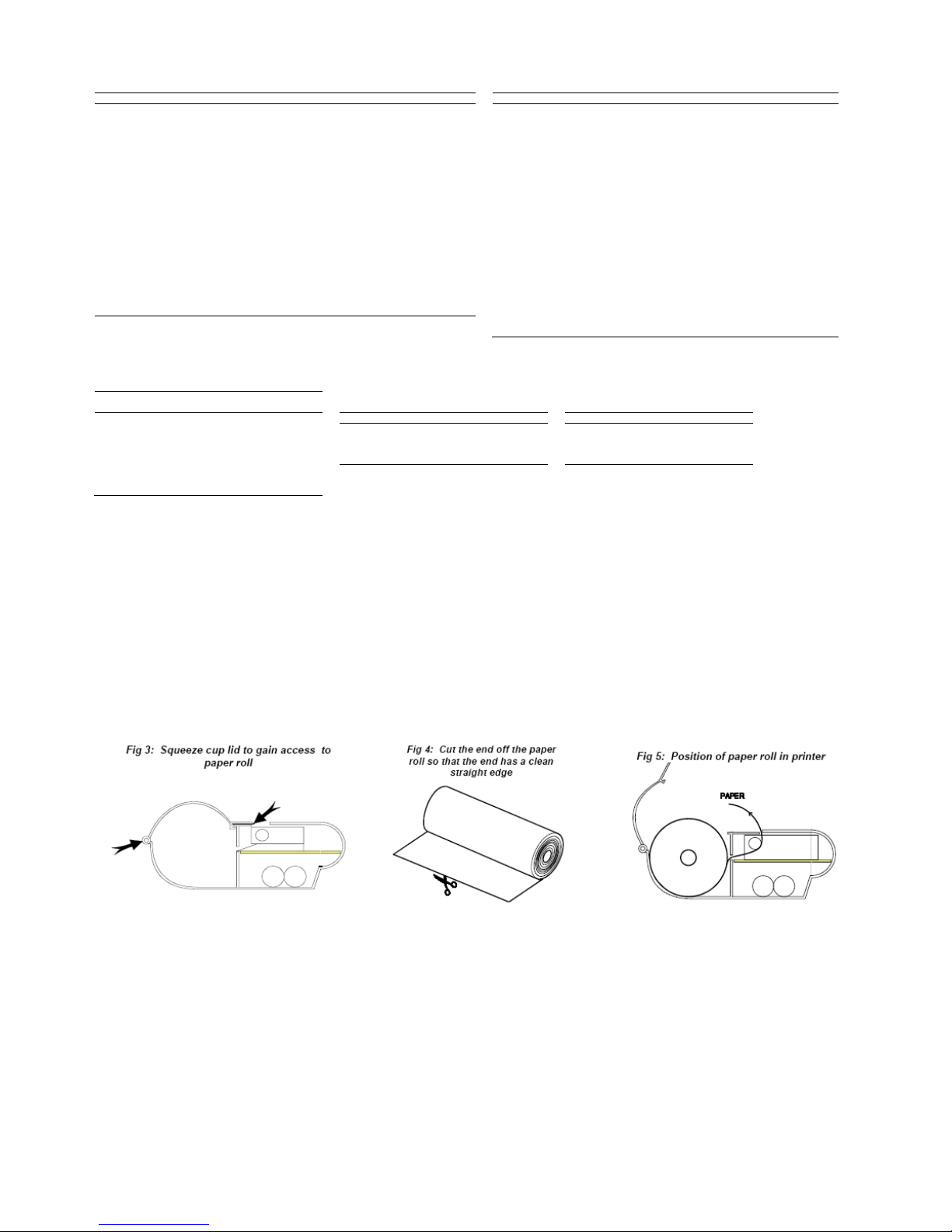

Check the batteries are sufficiently charged or that the power supply is correctly fitted and operational. Open the

paper cup lid and ensure that the roll is present and that there are no foreign objects inside the paper cup. Close

the lid, ensuring that the paper passes through the paper exit slot. Switch on the printer using the power switch

located on the left hand side of the printer. The Power indicator will light and the printer mechanism will reset.

Battery Charging

Connect the MCP9810-112 printer to the MPS power adapter and recharge the batteries as soon as the Status

LED lights continuously during printing.

If the batteries in the MCP9810-112 become exhausted, printing will become faint, erratic or not possible at all.

Turn off the MCP9810–112 and recharge the batteries for at least 1 hour before attempting further printing. The

MPS adapter cannot supply the full power requirements for the MCP9810-112 during printing, so the batteries must

be partially charged before printing is possible.

When the MCP9810-112 is first delivered there may be little or no charge in the printer’s batteries. The MCP9810-

112 should be turned off, connected to the MPS adapter and allowed to charge for 16 hours before it is used for

the first time.

It is permissible to leave the MCP9810-112 permanently connected to the MPS power adapter, constantly charging

the printer’s batteries between printouts. Alternatively the printer can be recharged from a 9-17VDC power supply,

ensure –ve centre pin connection.