1

CONTENT

1. Notice before start-up ..................................................................................................3

2. FU Series.....................................................................................................................4

2.1 Specifications......................................................................................................4

2.2 Outer Dimension.................................................................................................5

2.3 Terminal Wiring Diagram ....................................................................................6

2.4 Assembly & Wiring .............................................................................................7

3 FY Series ....................................................................................................................8

4. Terminal arrangement................................................................................................ 11

4.1 FY400 / FU48 Terminals ( 48mm x 48mm , DIN 1/16 )..................................... 11

4.2 FY600 Terminals ( 96mm x 48mm , DIN 1/8 )...................................................12

4.3 FY700 / FU72 Terminals ( 72mm x 72mm) .......................................................13

4.4 FY800 / FU86 Terminals ( 48mm x 96mm , DIN 1/8 ).......................................14

4.5 FY900 / FU96 Terminals ( 96mm x 96mm , DIN 1/4 ).......................................15

4.6 FY100 Terminals ( 175mm x 110mm ) ..............................................................16

4.7 FY101 Terminals ( 90mm x 90mm )..................................................................17

5. External dimension and panel cutout〈Unit:mm〉.................................................18

5.1 FY100...............................................................................................................18

5.2 FY101...............................................................................................................18

5.3 FY400~900 & FU48~96....................................................................................19

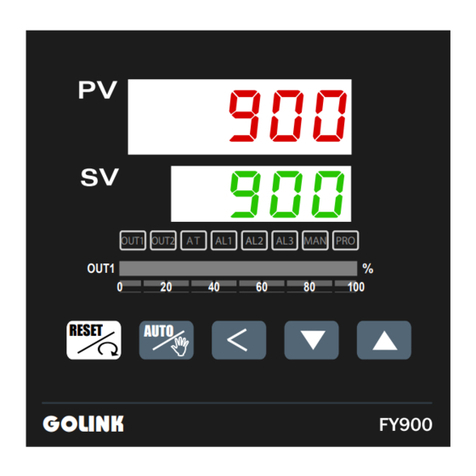

6. Parts description ........................................................................................................20

7. Operations .................................................................................................................21

7.1 Power On..........................................................................................................21

7.2 Change the Set Value (SV)...............................................................................21

7.3 Change the Alarm Value ...................................................................................21

7.4 Autotuning (AT).................................................................................................22

7.5 Programmable RAMP / SOAK (Only available for PFY model) ........................23

8. Operation levels.........................................................................................................24

8.1 Levels diagram .................................................................................................24

8.2 Lock function ....................................................................................................24

9. Parameters ................................................................................................................25

9.1 Level 1 (User Level) .........................................................................................25

9.2 Level 2 (PID Level) ...........................................................................................26

9.2.1 Level 2 parameters display /hiding condition ......................................26

9.2.2 Description of parameters....................................................................27

9.3 Level 3 (Input Level) .........................................................................................28

9.4 Level 4 (SET level) ...........................................................................................30

9.4.1 How to hide parameters (Use SET1~SET7) ........................................30

9.4.2 Special functions (Use SET8 / SET9 / SET0) ......................................31

9.4.3 Remote SV type selection ...................................................................32

9.4.4 Output mode selection (Use OUTY) ....................................................32

9.4.5 Modify caution .....................................................................................32

9.5 Program Level (Only displayed in programmable controller) .........................33

9.5.1 Description of parameters....................................................................33