Contents

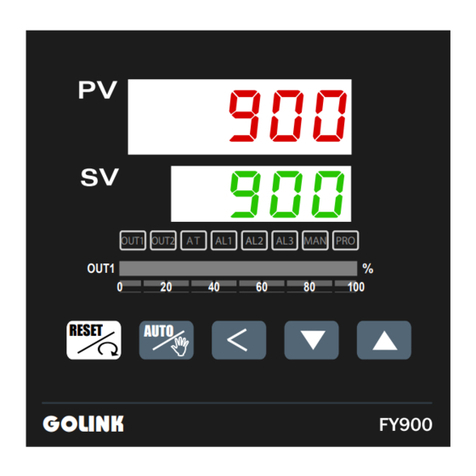

1 Set up of the controller...........................................................................................1

2 System Configuration ............................................................................................2

2.1 RS485 Communication System.................................................................2

2.2 RS232 Communication System.................................................................2

3 Wiring Connection.................................................................................................3

3.1 RS485 Communication Wiring..................................................................3

3.2 RS232 Communication Wiring..................................................................3

4 MODBUS RTU Protocol.......................................................................................4

4.1 Message Configuration..............................................................................4

4.2 ID Number (Slave Address).......................................................................4

4.3 Function Code............................................................................................4

4.4 Data............................................................................................................4

4.5 Error Check CRC.......................................................................................4

4.6 Abnormal Code..........................................................................................5

4.7 Message example of RTU mode................................................................5

4.7.1 Reading ( Read PV from slave controller 1)..................................5

4.7.2 Setting (Set SV = 10.0 to slave controller 1).................................5

4.7.3 Setting (Set SV = 10.0 and OUTL=100.0 to slave controller 1)....6

5 MODBUS ASCII Protocol.....................................................................................7

5.1 Message Configuration..............................................................................7

5.2 ID Number(Slave Address)........................................................................7

5.3 Function Code............................................................................................7

5.4 Data............................................................................................................7

5.5 Error Check LRC.......................................................................................7

5.6 Abnormal Code..........................................................................................8

5.7 Message example of ASCII mode..............................................................8

5.7.1 Setting (Set SV = 10.0 to slave controller 1).................................8

5.7.2 Setting (Set SV = 10.0 and OUTL=100.0 to slave controller 1)....9

6 TAIE Protocol......................................................................................................10

6.1 Message Configuration............................................................................10

6.2 Command.................................................................................................10

6.3 ID Number ...............................................................................................10

6.4 Register Address ......................................................................................10

6.5 Data..........................................................................................................10

6.6 Check Sum...............................................................................................11

6.7 Message example of TAIE Protocol ........................................................11