-7-

1. Push the power cord plug into a wall outlet.

2. Press the power switch.

When the

“

power switch

”

is pressed, the

“

power

lamp

”

is lit. At the same time, the

“

water supply lamp

”

is lit and an alarm gose o to indicate the

“

need for water supply

”

.

3. Add water or hot water to the water tank.

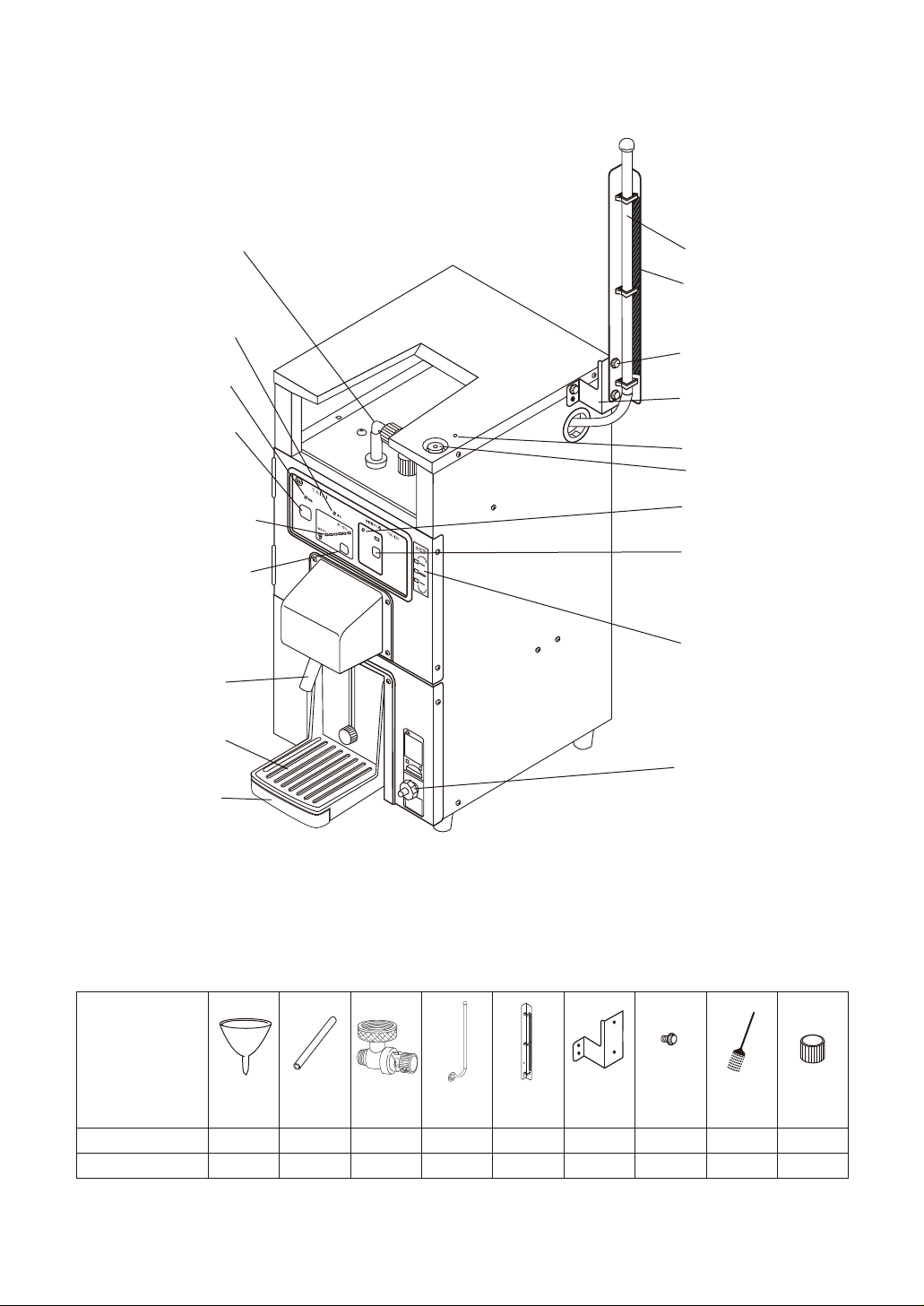

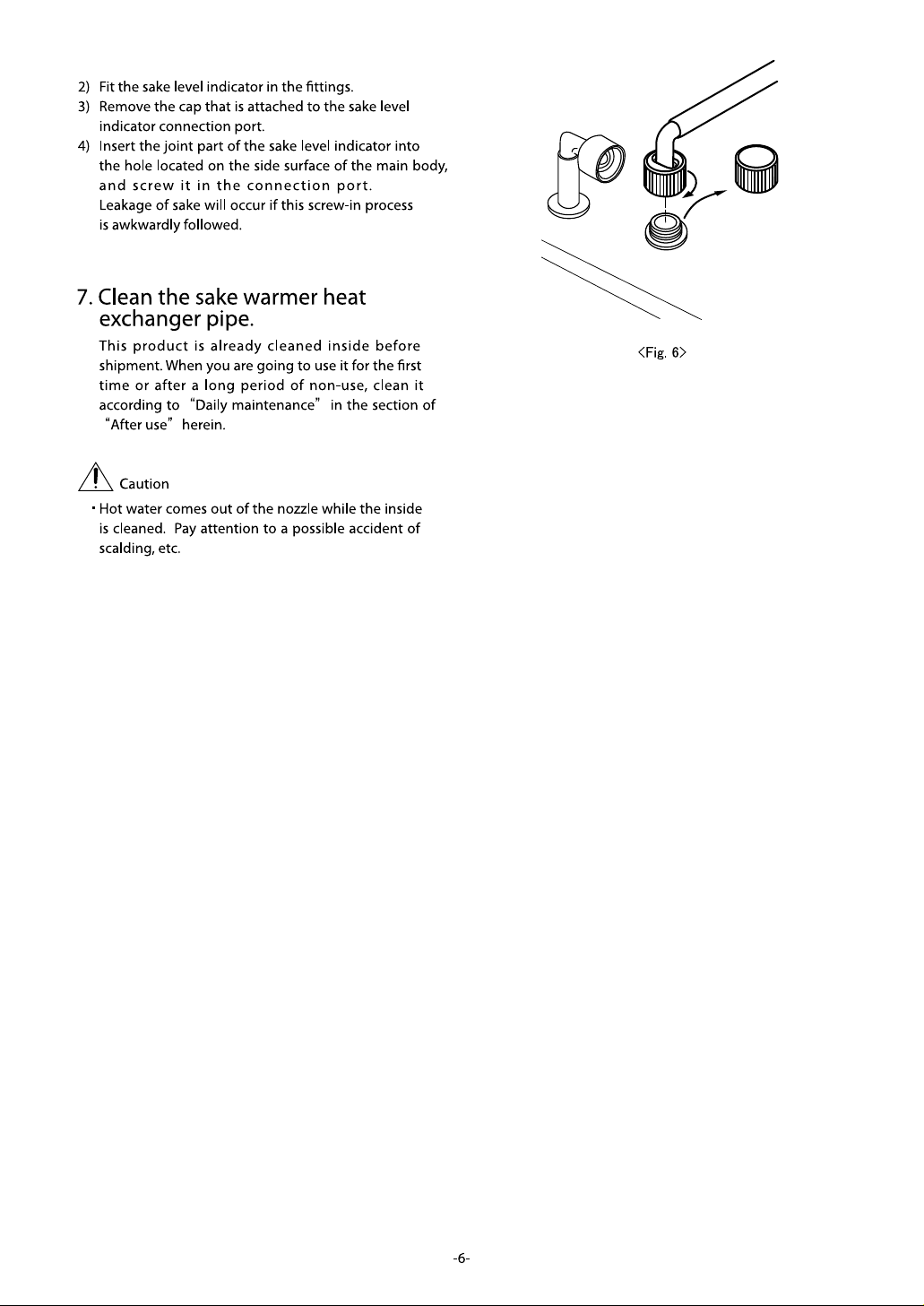

Use the provided funnel and ll water or hot water until

the water level reaches the

“

optimum

”

level on the

water level indicator. (Fig. 7)

・The water tank holds approximately 4.7 liters

of water. (About 6.7 liters for the TSK-220B, TSK-

230B, and TSK-420B)

・The water supply lamp goes out and alarm stops

when the water level reaches the lowest level

but keep adding water until it reaches the

“

optimum

”

level.

・

Excessive water (beyond the maximum level) will be

discharged through the overow outlet.

Caution

・Never feed any liquid other than water or hot water.

4. Adjust the sake warming temperature.

1) When the

“

temperature control switch

”

is

pressed once, the temperature setting mode is assumed.

Initial setting is at [OFF].

・The setting indication and the sake warming

temperature are as specied below. However,

they can change under various conditions, and

they should be used as a guideline.

Lukewarm Approx. 45°C

Hot Approx. 65°C

2) Each time the

“

temperature control switch

”

is

pressed once, the temperature indicator lamp

moves up from one after another along the

diagonal line. (Fig. 8)

Instructions for Use

<Fig. 7>

<Fig. 8>