-5-

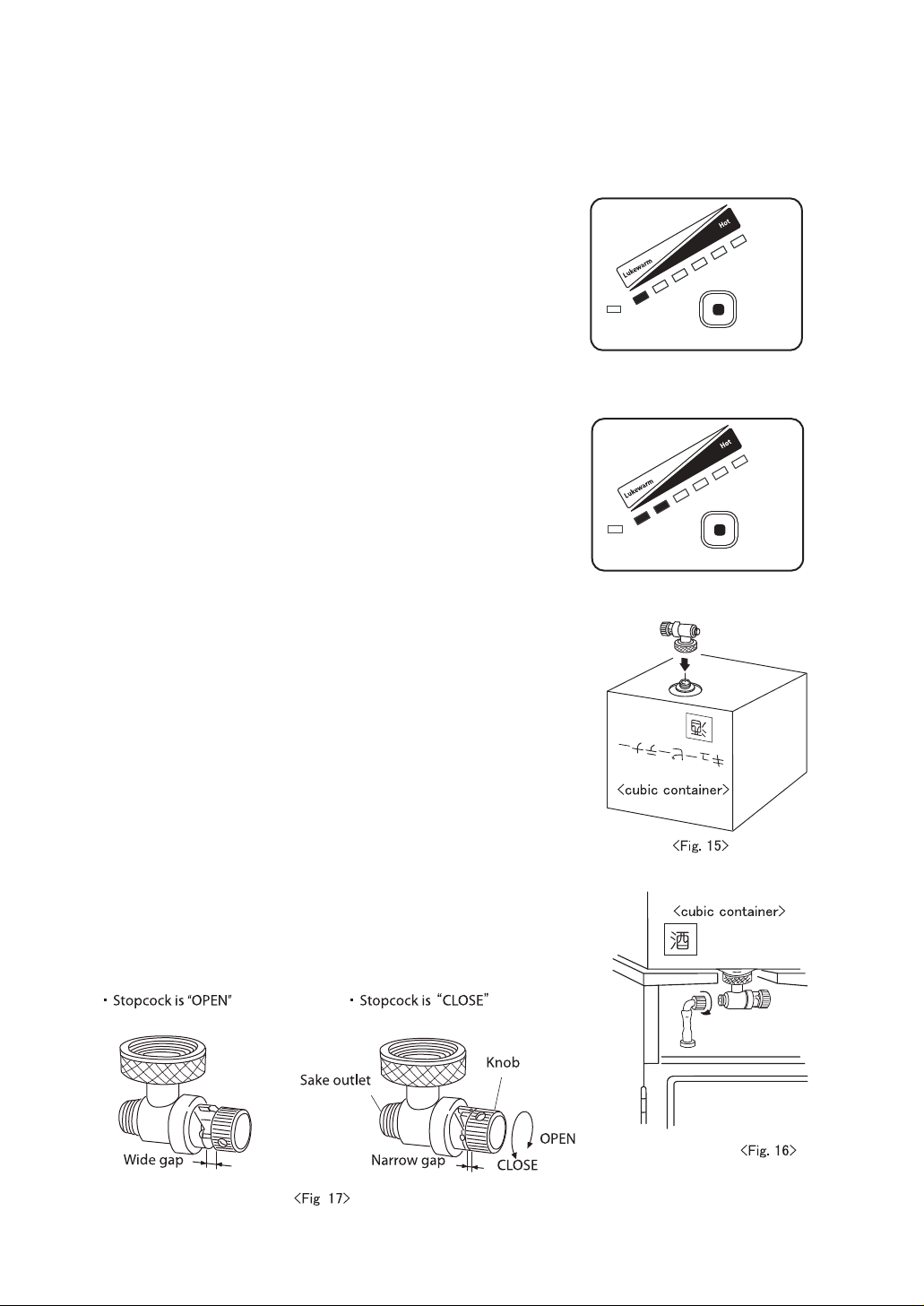

AfterUse

1. Dailymaintenance(cleaningofsakepassage)

(1) Removetheusedcubiccontainerinthefollowingprocedure:

・LeavethepowerswitchturnedON.

1) Turntheknobofthestopcocktotheleftandadjustittothe

“

CLOSE

”

position.Throwthenozzle(sakeoutlet)

downtodrainthesakeremaininginside.

2) Afterthenozzlehasbeenthrowndown,removethejointpartbetweenthestopcockandthejointhose.

Foramachinethathasnosakelevelindicator,theinnersakecannotbedrainedunlessthisworkisfinishedfirst.

3) Whentheinnersakehasbeendrainedout,returnthenozzleandremovethecubiccontainerfromthe

mainbody.

4) Removethestopcockfromthecubiccontainer.

(2) Pourabout2litersofhotwater(below.70℃)inacubiccontainerintendedforcleaning(anemptycubiccontainer).

Aftermountingthestopcock,placeitonthemainbodyandconnectthestopcocktothejointhose.

・Neveruseanydetergent.

(3) placeanemptycontainerunderthenozzletodrainhotwater.Turntheknobofthestopcocktotherightand

adjustittothe

“

OPEN

”

position.Pushthenozzlestraightdownorpressthe

“

manualdispensingswitch.

”

(4) Hotwatercomesoutofthenozzleandthepipeinsideiscleaned.

(5) Aftercleaning,removethecubiccontainerforcleaningintheprocedureof(1)aboveandturnthepowerswitchoff.

・Thedrainedsakeshouldbeusedforcookingandsoon.Aftercleaning,however,somewaterdropsmay

remaininside.Whenyoudispensesakenexttime,drainsomeatthebeginning.

2.

3.

Waterinthewaterbathtankshouldbereplacedonceamonth.

Atthattime,turnoffthepowerswitchwithoutfailandopenthewaterdrainvalve

connectingthedraintubingtodrainwater.

4.

5.

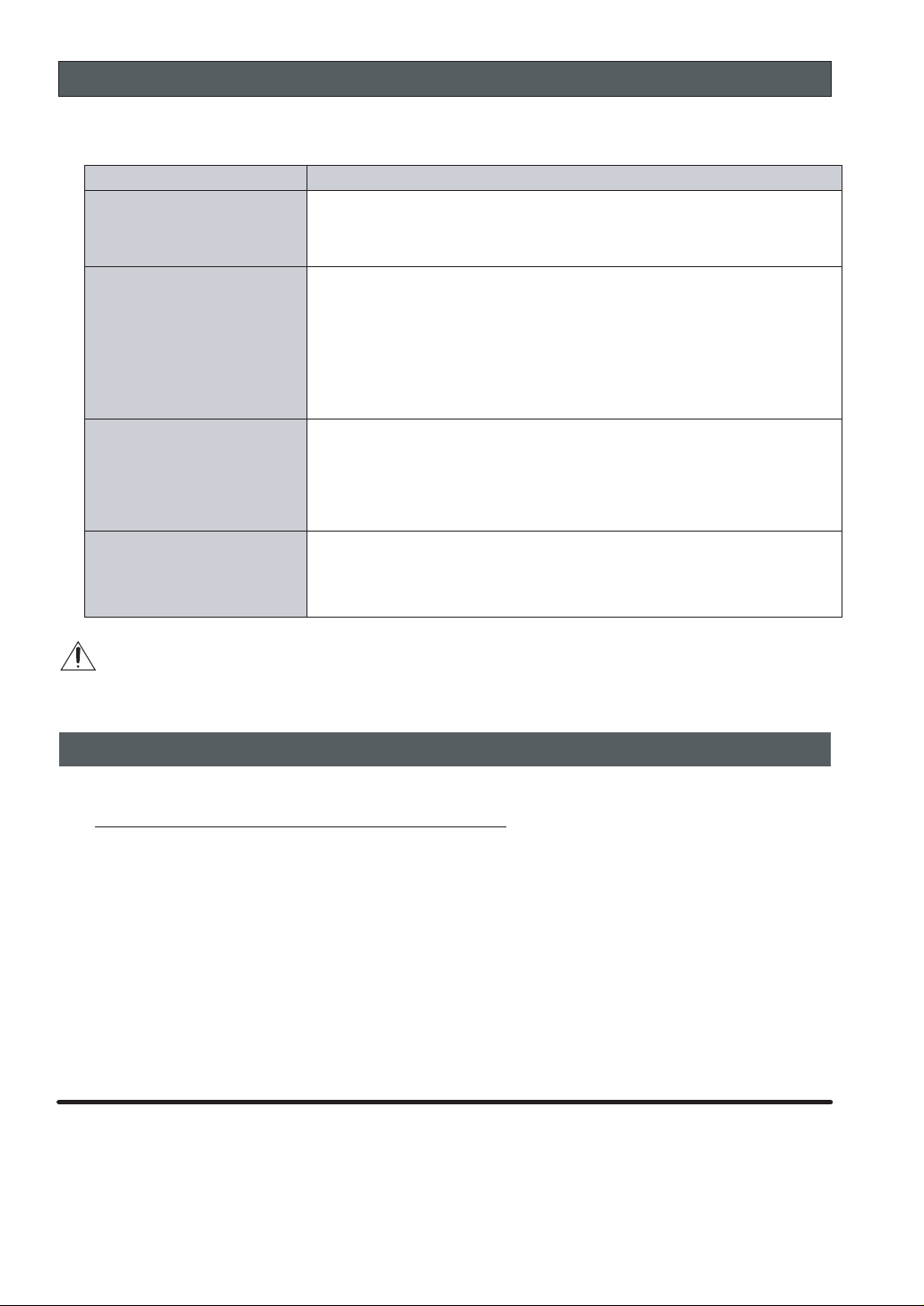

Cleanthenozzleatleasttwiceamonth.(Fig.22)

Gentlyscrubthesensorelectrodeonthetipofthenozzlewithatoothbrush.

Maintenanceforserverbottleholderandtray

Removetheserverbottleholderfromthemainunitand

removethetrayfromtheserverbottleholder.

Neatlywashthemwithwarmwater.

<Fig. 22>

Nozzle

Sensor

Careofmainunit

Wipemainunitwithadrycloth.Otherwise,wipeitwithaclothdippedinaneutraldetergent

solutionorsoapandwater,thenwipeitwellwithadrycloth.

Thefrontofthemachineismadeofresin,sodonotusepaintthinnerorothervolatilefluidsoralkaline

detergents.