S88-3 tams elektron k

3.2. Solder ng properly!

Use a solder ng ron w th temperature control, wh ch you set to approx. 300 °C.

Only use electron c solder w th a flux.

Never use solder ng water or solder ng grease when solder ng electron c c rcu ts. These

conta n an ac d that destroys components and conductor paths.

Insert the connect ng w res of the components as far as poss ble through the holes of the

board w thout us ng force. The body of the component should be close above the board.

Make sure that the polar ty of the components s correct before solder ng them.

Solder qu ckly: solder ng for too long can coffe pads or tracks to become detached or even

destroy components.

Hold the solder ng t p on the solder ng po nt n such a way that t touches the component

w re and the pad at the same t me. Add (not too much) solder s multaneously. As soon as

the solder beg ns to flow, remove t from the solder ng po nt. Then wa t a moment for the

solder to flow well before remov ng the solder ng ron from the solder ng jo nt.

Do not move the component you have just soldered for about 5 seconds.

A clean, non-ox d sed (scale-free) solder ng t p s essent al for a perfect solder ng jo nt and

good solder ng. Therefore, before each solder ng, w pe off excess solder and d rt w th a

damp sponge, a th ck damp cloth or a s l cone w per.

After solder ng, cut off the connect ng w res d rectly above the solder ng po nt w th a s de

cutter.

After assembly, always check each c rcu t aga n to ensure that all components are correctly

nserted and polar sed. Also check that no connect ons or tracks have been acc dentally

br dged w th t n. Th s can lead not only to malfunct on, but also to the destruct on of

expens ve components. You can re-l quefy excess solder w th the clean hot solder ng t p.

The solder then flows from the board to the solder ng t p.

Preparation

Put the sorted components n front of you on your workbench.

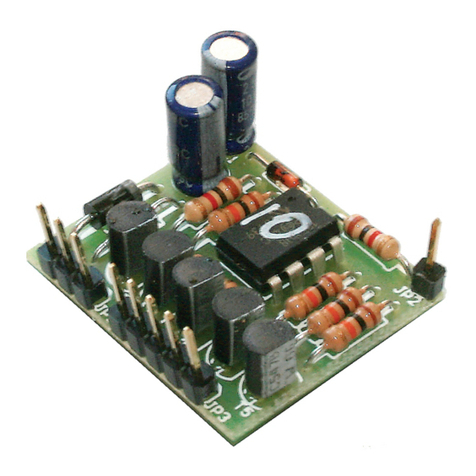

The separate electron c components have the follow ng spec al features you should take nto

account n assembl ng:

Resistors

Res stors reduce current.

The value of res stors for smaller power rat ngs s nd cated through colour r ngs.

Every colour stands for another f gure. Carbon f lm res stors have 4 colour r ngs.

The 4th r ng (g ven n brackets here) nd cates the tolerance of the res stor (gold

= 5 %).

Value: Colour r ngs:

1 kbrown - black - red (gold)

4,7 kyellow - v olet - red (gold)

100 kbrown - black - yellow (gold)

10 | Assembl ng the k t