English PZS-2

Table of contents

1. Getting started............................................................................3

2. Safet instructions.......................................................................5

3. Safe and correct soldering...........................................................7

4. Operation overview.....................................................................9

5. Technical specifications..............................................................13

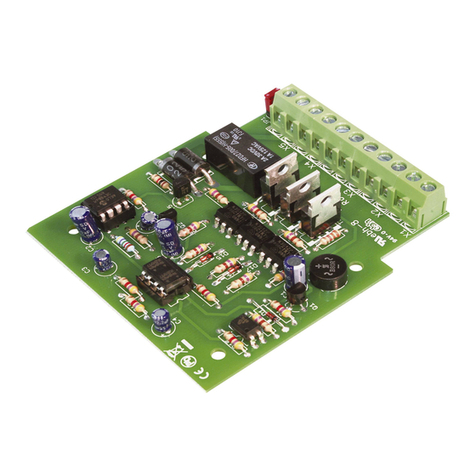

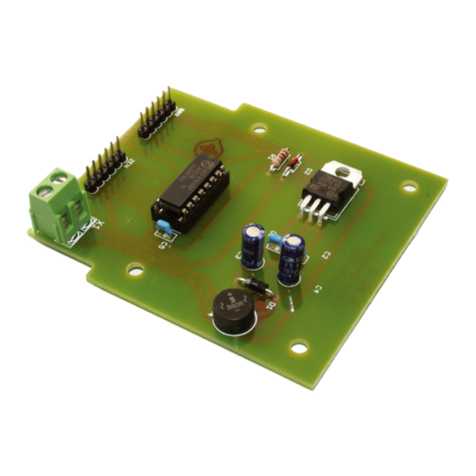

6. Assembling the kit.....................................................................14

7. Functional test..........................................................................23

8. Connecting the PZS-2................................................................24

8.1. Schema............................................................................24

8.2. Dividing the shuttle-train section into parts.........................25

8.3. Connecting the power suppl .............................................25

8.4. Connecting the shuttle-train section to the PZS-2................27

9. Operation.................................................................................30

10. Programming the PZS-2.............................................................33

11. Check list for troubleshooting.....................................................36

12. Guarantee bond........................................................................38

13. EU declaration of conformit ......................................................39

14. Declarations conforming to the WEEE directive...........................39

© 01/2015 Tams Elektronik GmbH

All rights reserved. No part of this publication ma be reproduced or

transmitted in an form or b an means, electronic or mechanical,

including photocop ing, without prior permission in writing from Tams

Elektronik GmbH.

Subject to technical modification.

Page 2