1SAFETY AND WARNINGS ......................................................................................................................3

2WARRANTY .............................................................................................................................................3

3PRECAUTIONS AND HAZARDS ............................................................................................................4

4INSTALLATION........................................................................................................................................5

4.1 IMPORTANT ..........................................................................................................................................................5

4.2 UNPACKING..........................................................................................................................................................5

2.1 TILTING................................................................................................................................................................5

2.2 VENTILATION........................................................................................................................................................5

3BATH LIQUID...........................................................................................................................................6

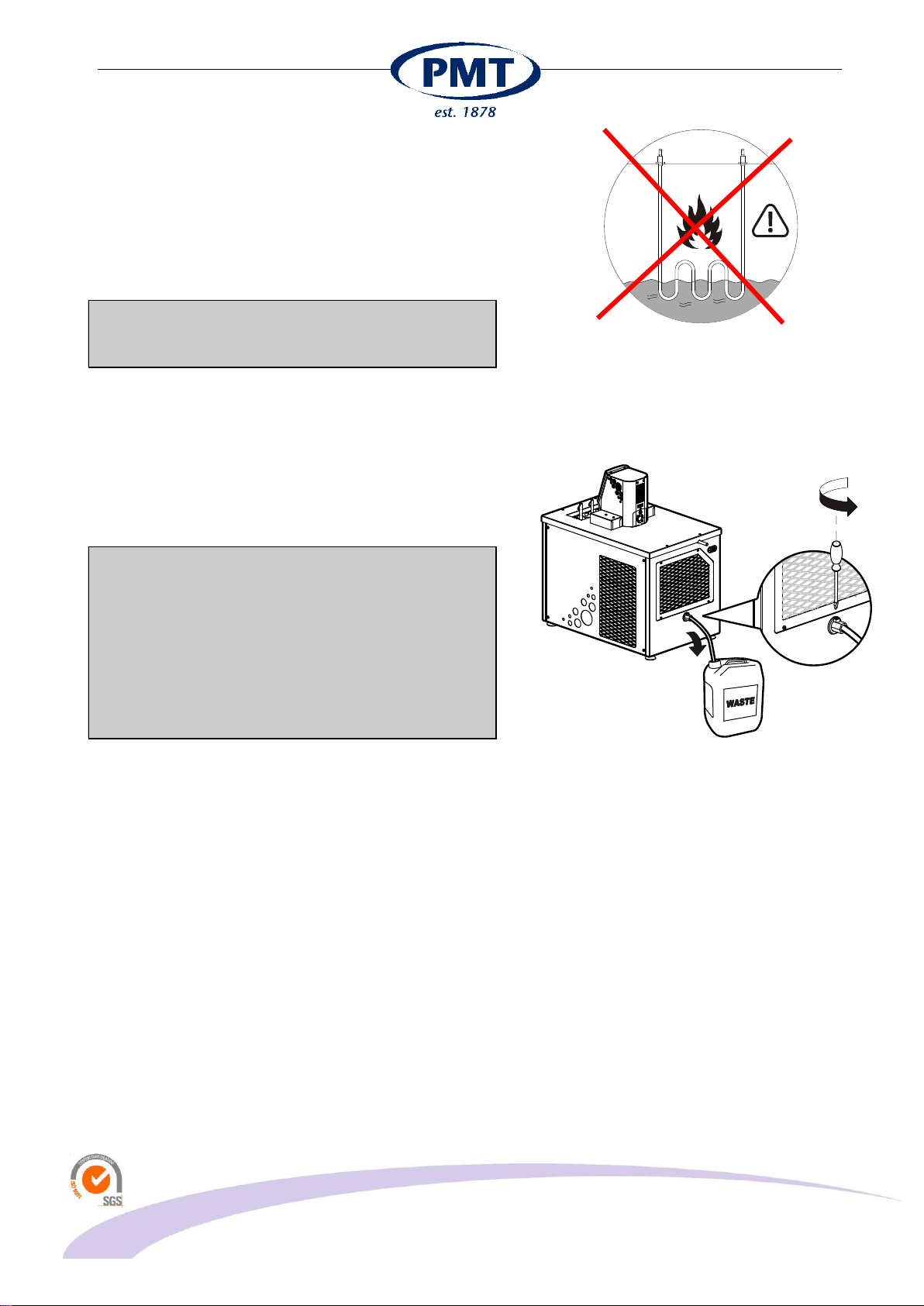

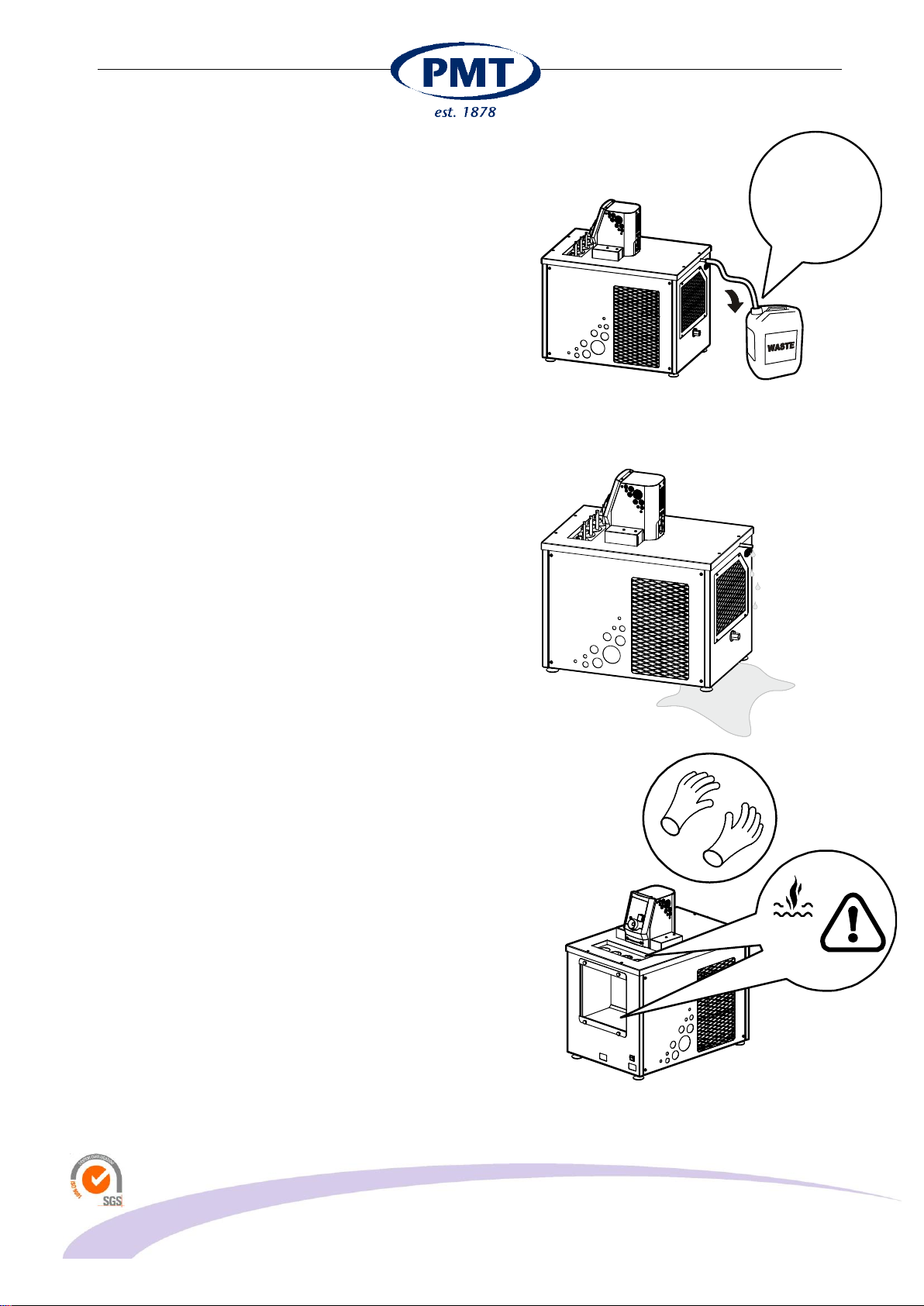

3.1 DRAIN BATH FLUID ................................................................................................................................................7

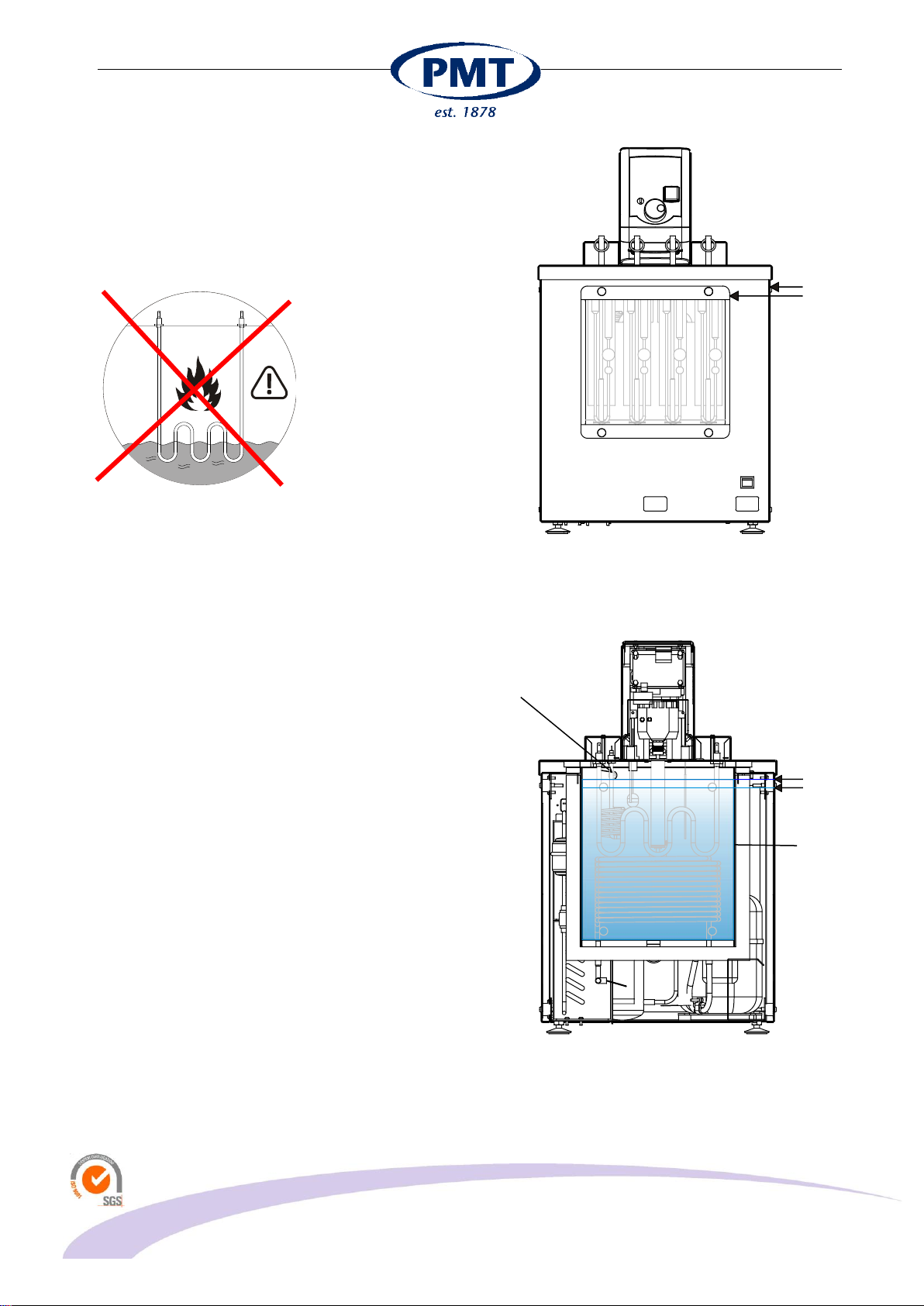

3.2 BATH FLUID LEVEL.................................................................................................................................................8

3.3 SAFETY AND PROTECTION......................................................................................................................................9

3.4 COOLING ...........................................................................................................................................................10

3.5 CONNECTING .....................................................................................................................................................11

4INTRODUCTION.....................................................................................................................................12

4.1 GENERAL...........................................................................................................................................................12

4.2 CONSTRUCTION..................................................................................................................................................12

4.3 STIRRER............................................................................................................................................................12

4.4 TEMPERATURE CONTROL AND SETTING .................................................................................................................12

4.5 FRONT PANEL ....................................................................................................................................................13

4.6 OVERVIEW MENU ITEMS.......................................................................................................................................13

5SAFETY SYSTEMS................................................................................................................................15

5.1 MECHANICAL OVER-TEMPERATURE PROTECTION....................................................................................................15

5.2 LEVEL PROTECT..................................................................................................................................................15

6OPERATING THE SYSTEM...................................................................................................................16

6.1 QUICK START.....................................................................................................................................................16

6.2 MENU ITEMS ......................................................................................................................................................16

7MANUAL TUNING..................................................................................................................................20

8MAINTENANCE......................................................................................................................................21

9TROUBLE SHOOTING...........................................................................................................................22

9.1 APPLICATION ERRORS .........................................................................................................................................22

9.2 BATH MALFUNCTION............................................................................................................................................22

9.3 PROBLEMS WITH SET POINT .................................................................................................................................22

9.4 FAULTY TEMPERATURE READING OR TEMPERATURE OFFSET ....................................................................................22

9.5 BATH TEMPERATURE DOES NOT BECOME STABLE ...................................................................................................23

9.6 BATH DOESN'T REACH SP....................................................................................................................................23

9.7 BLUE LED BLINKS ON FRONT PANEL .....................................................................................................................23

9.1 OVER-TEMPERATURE SAFETY THERMOSTAT...........................................................................................................24

10 SPECIFICATIONS ..............................................................................................................................25

10.1 PRECISION OF CONTROL......................................................................................................................................25

10.2 COOLDOWN .......................................................................................................................................................25

10.3 SETTLING TIME BATH FLUID ..................................................................................................................................25

10.4 HOMOGENEITY AND ΔT .......................................................................................................................................26

11 SPARE PARTS LIST ..........................................................................................................................28

12 EC DECLARATION OF CONFORMITY.............................................................................................29

13 DISCLAIMER ......................................................................................................................................30