9

!

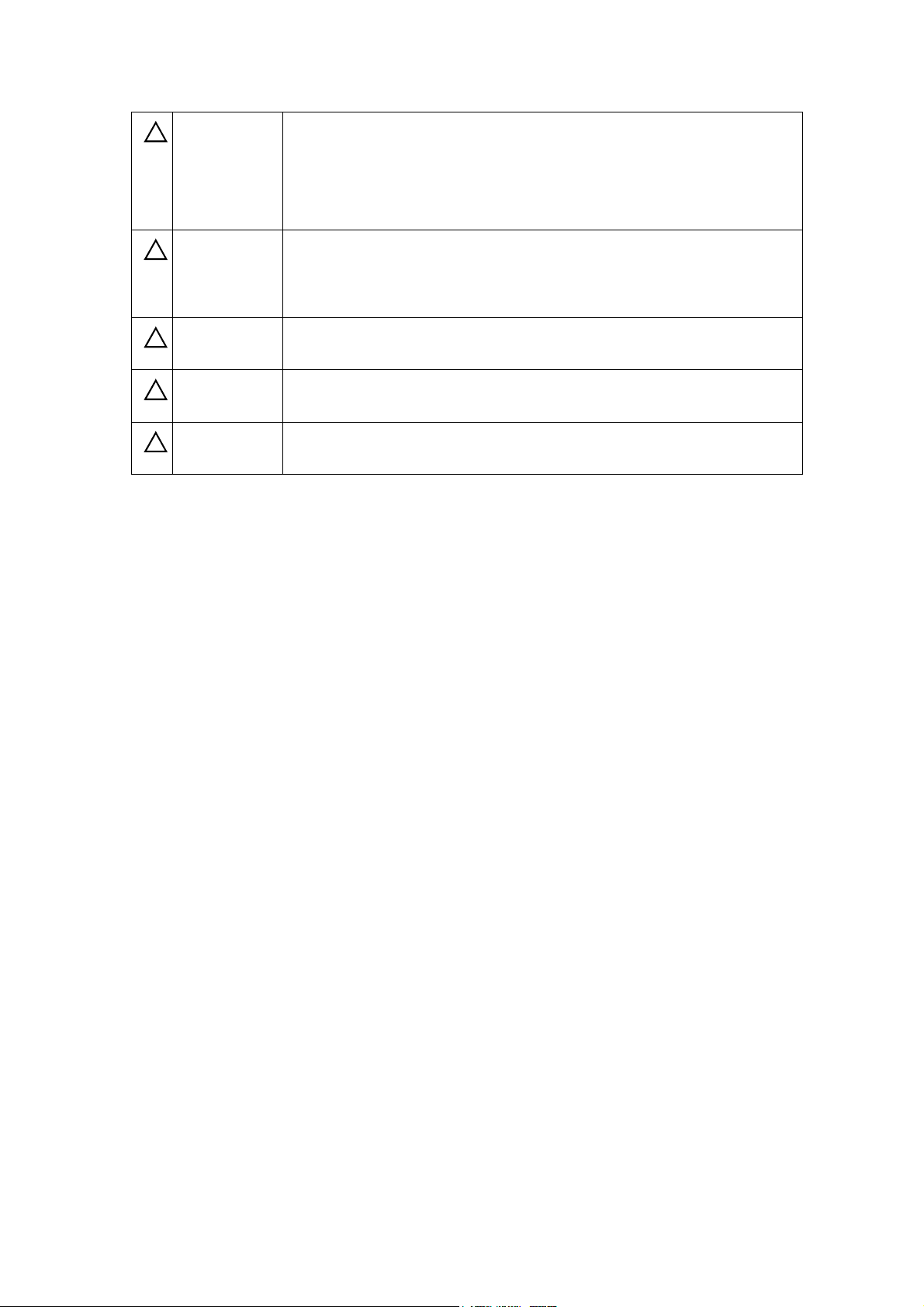

WARNING

Do not open the lid at any time during the heating cycle. The

introduction of air (oxygen) may form an explosive mixture

with the volatile coking products formed. Open the oven only

after oven temperature falls below 250℃during the cooling

step.

!

WARNING After the test is completed the oven seal lid still holds high

temperature. Be sure to make operations by holding the handle

(knob). If you touch the metal part, there is a danger of

burning.

!

WARNING The part surrounding the oven gets considerably heated while

testing. Be careful not to touch it with bare hands, etc.

!

CAUTION Maintain nitrogen flow until after the vial holder has been

removed from the oven.

!

CAUTION Handle oven lid with care and keep it on the lid rest. Gas leak

may occur if the sealing surface has a damage.

(1) With the oven at less than 100℃, place the vial holder into the oven chamber and

secure lid. When placing the vial holder, care should be taken not to touch the

thermocouple with sample basket feet.

(2) Confirm the nitrogen gas pressure gauge indicates 150kPa and the gas flow meter

shows 150ml/min, then press the START switch.

(3) The flow rate of nitrogen increases to 600ml/min automatically for the first 10

minutes after pressing the START switch. If the flow rate is not 600ml/min, adjust

N2 needle valve for 600ml/min (0.60L/min by flow meter).

(4) After this, the temperature(1) and flow rate of nitrogen are controlled as indicated

in Fig. 2.To complete the temperature and flow program(2) in 98 minutes.

(5) The buzzer intermittently sounds for about 10 seconds and “P.End” is shown on

the setting temperature display on the program controller.

(6) After “P.End” is indicated, press the RESET switch. The programmable controller

is reset and the “P.End” disappears.

(7) When oven temperature is less than 250℃, place the lid to the lid rest to cool down

and remove the vial holder using hook for further cooling in desiccator.

(8) Start the next test or turn the MAIN switch OFF(3) after the oven temperature falls

below 100℃.

Note 1 - For the safety, programmable controller cuts the heater output and sounds

buzzer continuously when the oven is abnormally heated above 550℃. Furthermore, a

separate circuit performs the same function when the oven heated above 600℃.

Turn off the MAIN switch and resolve the trouble before starting your next test.

Note 2 - ACR-M3 is preprogrammed to run carbon residue test. The detail of the

program is described under the procedure of the ASTM D4530.

Although the program has been entered and then locked prior to shipment, no attempt

should be made to alter the program. If, on the other hand, any variance from the

prescribed test conditions is found, consult Tanaka or its distributor for re-adjustment.

Note 3 – After resetting the Tester or when the Tester is idling, the nitrogen gas flow

rate is set at 150ml/min. With the MAIN switch turned off, the nitrogen gas flow stops