1

TABLE OF CONTENTS

FORWARD ……………………………………………………………………... 2

INTENDED READER OF THIS MANUAL …………………………………. 2

REVISIONS ……………………………………………………………...……... 2

SAFE OPERATION …………………………………………………………… 2

WARNING ……………………………………………………………………... 3

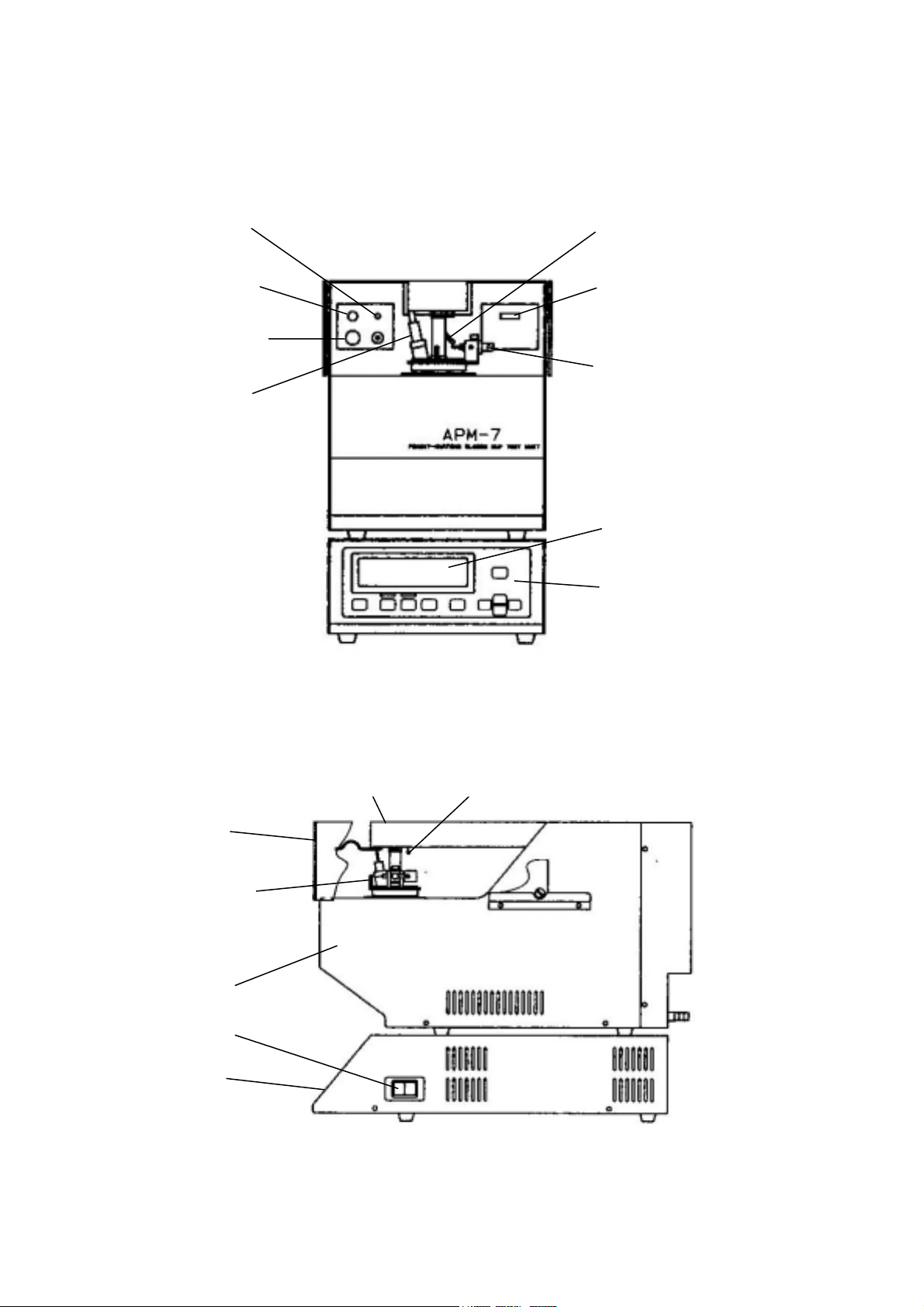

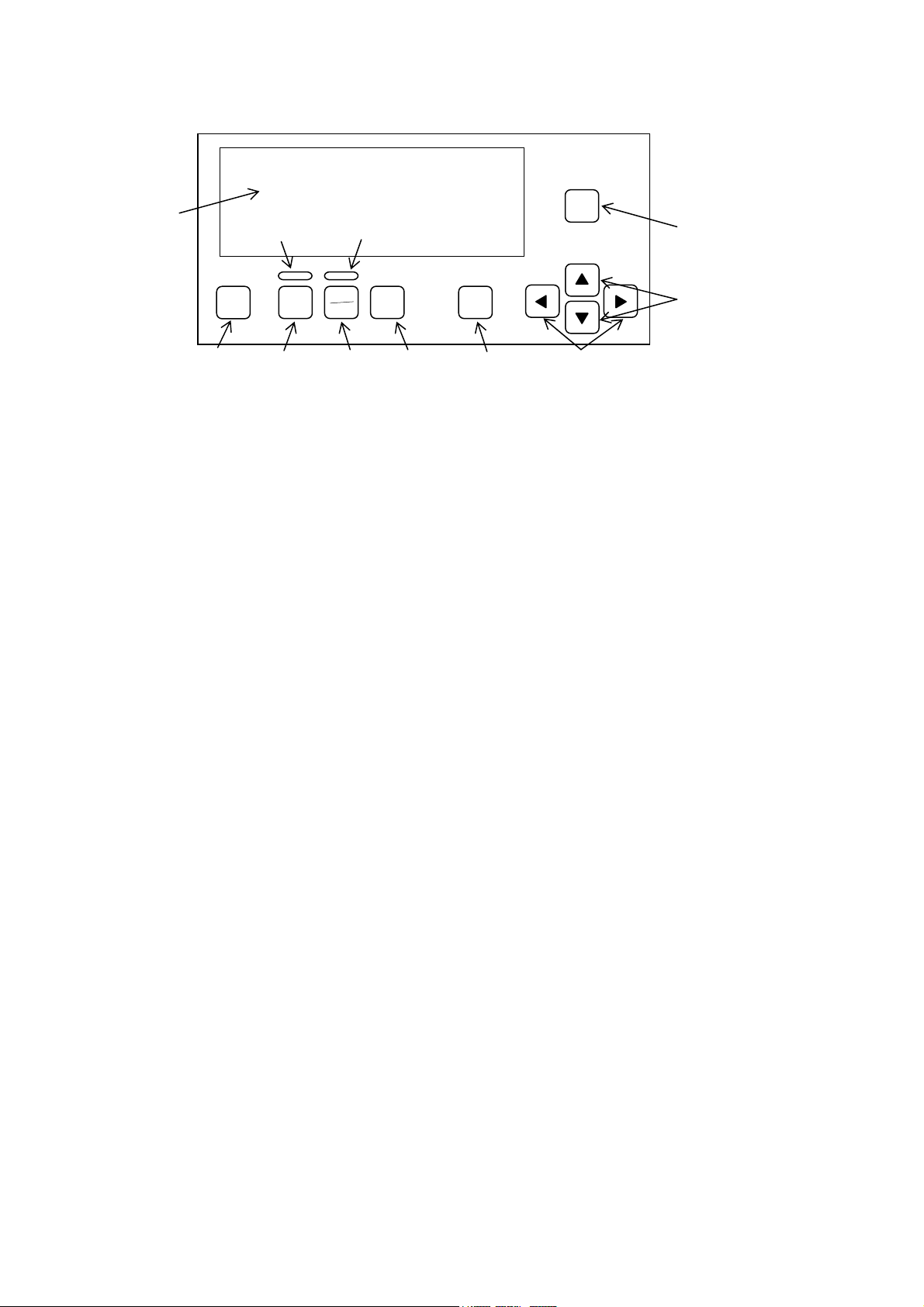

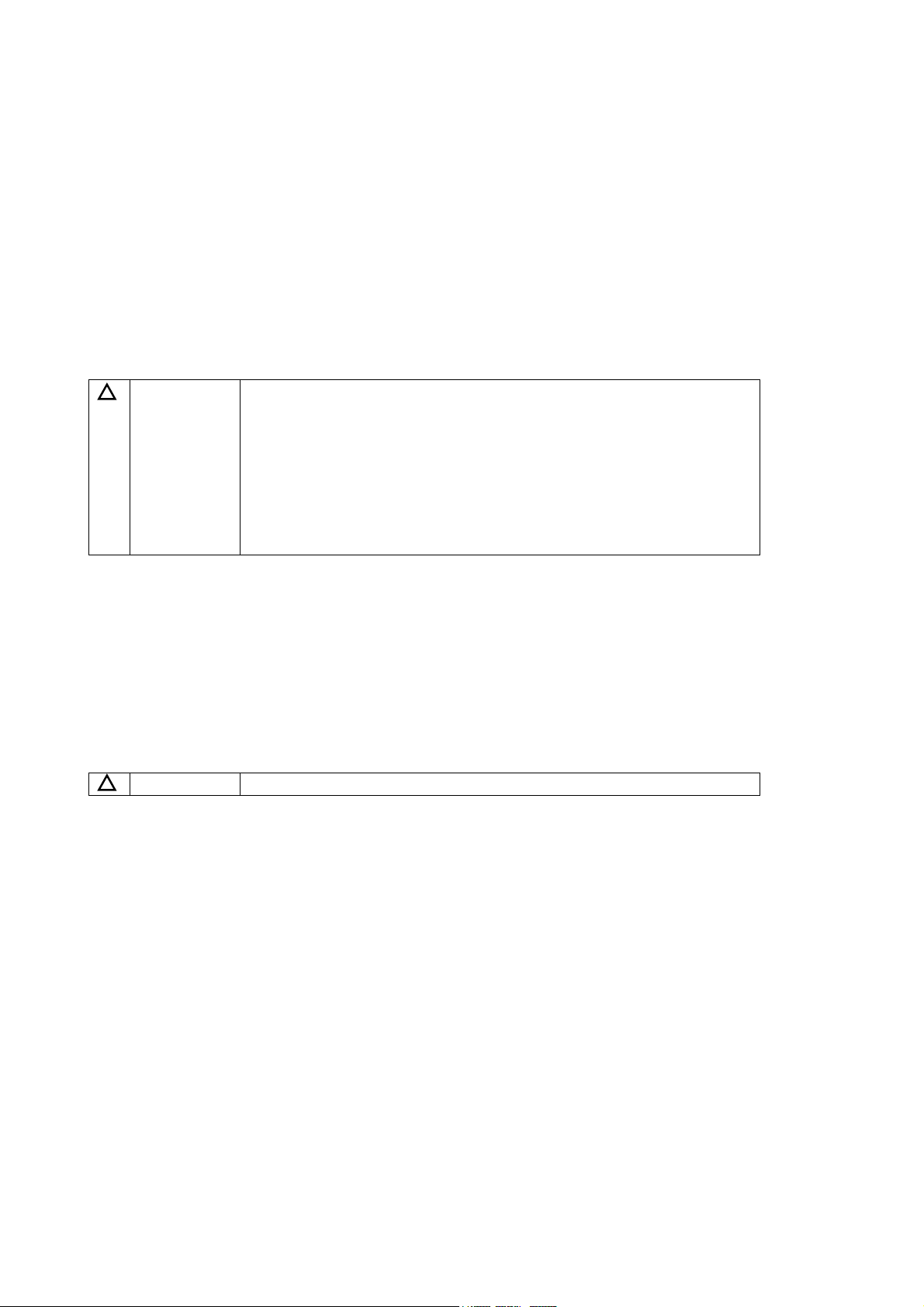

1. Overview of Model APM-7 ………………………………………………..... 4

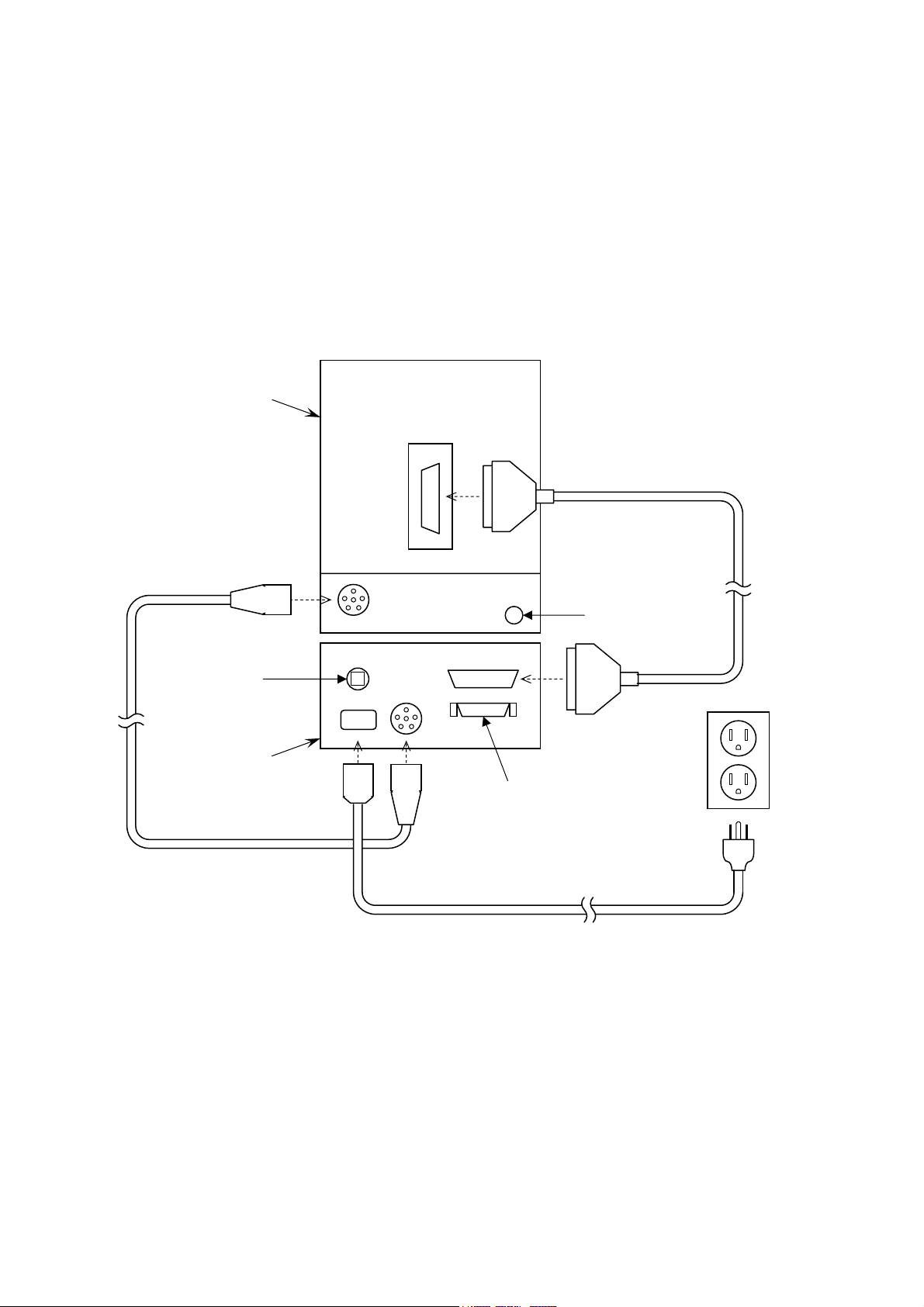

2. Installation …………………………………………………………………… 7

2.1 Installation Site …………………………………………………...………. 7

2.2 Electric Connections …………………………………………..………….. 7

2.3 Gas Connection ……………………………………..…………………….. 7

3. Operation ………..…………………………………………………………... 9

3.1 Power ON …………………………………………………………………. 9

3.2 Entering a Barometric Pressure Value …………………………………. 9

3.3 Select Test Procedure and Mode………………………………………… 10

3.3.1 ASTM Mode ………………………………………………………….. 10

3.3.2 Special Mode ………………………………………………………….. 10

3.3.3 User’s Custom Mode …………………………………………………..10

3.3.4 Simulated TAG Mode ………………………………………………… 10

3.4 Test Procedure in ASTM Mode ………………………………………… 10

3.4.1 Setting of Expected Flash Point ……………………………………... 10

3.4.2 Preparation of Test Cup and Sample ……………………………….. 11

3.4.3 Test Start ……………………………………………………………… 11

3.4.4 Start of Ignition Source Application ………………………………... 11

3.4.5 Flash Detection ……………………………………………………….. 12

3.4.6 Completion of a Test …………………………………………………. 14

3.5 Test by Special Mode ……………………………………………………. 14

4. Data Storage Function …………………………………………………..…. 15

5. In Case of Abnormal Operation or Trouble ……………………………… 16

6. Safety ………………………………………………………………………… 16

6.1 Gas Piping (When Gas Ignition is used) ……………………………….. 16

6.2 Prevention of Sample from Catching Fire ……………………………… 16

7. Post-sales Servicing ………………………………………………………… 17

8. Precaution in Case of Loss of Instruction Manual ………………………. 17

9. Caution when Transferring This Tester ………………………………….. 17

10. Specifications ………………..…………………………………………….. 17