Tandberg Data SUPERLOADER DLT - User manual

Other Tandberg Data Network Hardware manuals

Tandberg Data

Tandberg Data RDX QuikStor User manual

Tandberg Data

Tandberg Data MSERIES User manual

Tandberg Data

Tandberg Data SUPERLOADER DLT MAGAZINE User manual

Tandberg Data

Tandberg Data MSERIES FC USER User manual

Tandberg Data

Tandberg Data RDX QuikStation 4 User manual

Tandberg Data

Tandberg Data SLR AUTOLOADER - SERVICE AND Installation and operating manual

Tandberg Data

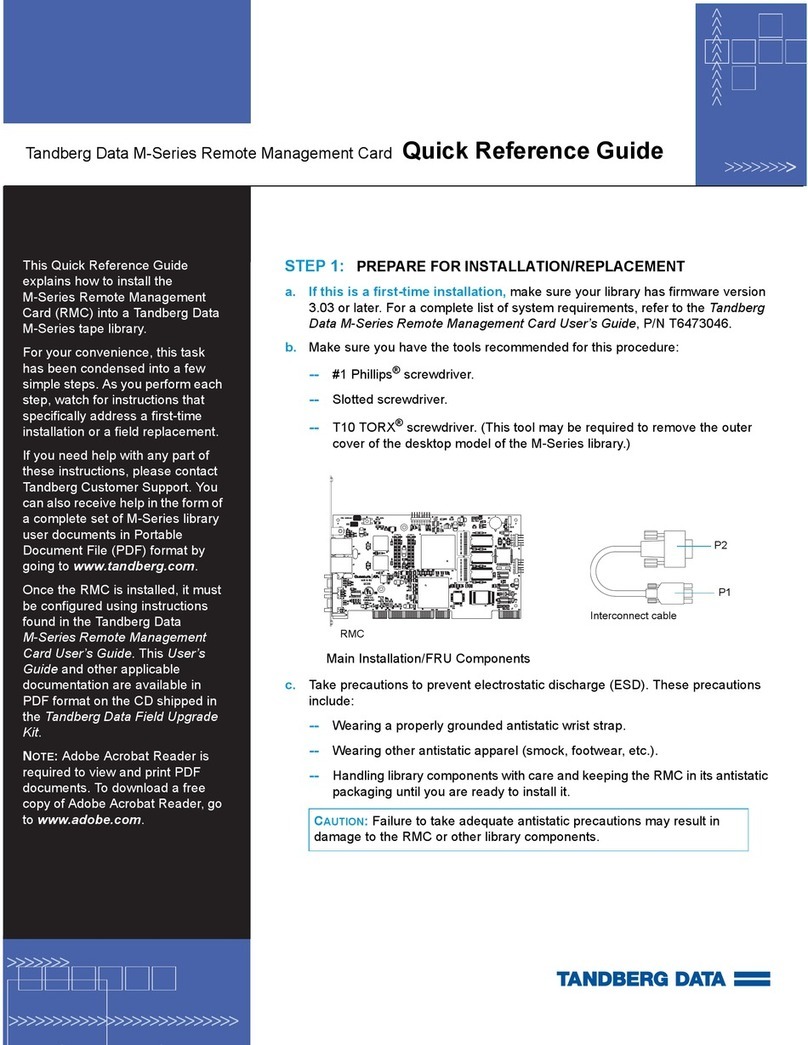

Tandberg Data MSERIES RMC USER User manual

Tandberg Data

Tandberg Data BARCODE READER User manual

Tandberg Data

Tandberg Data StorageLoader User manual

Tandberg Data

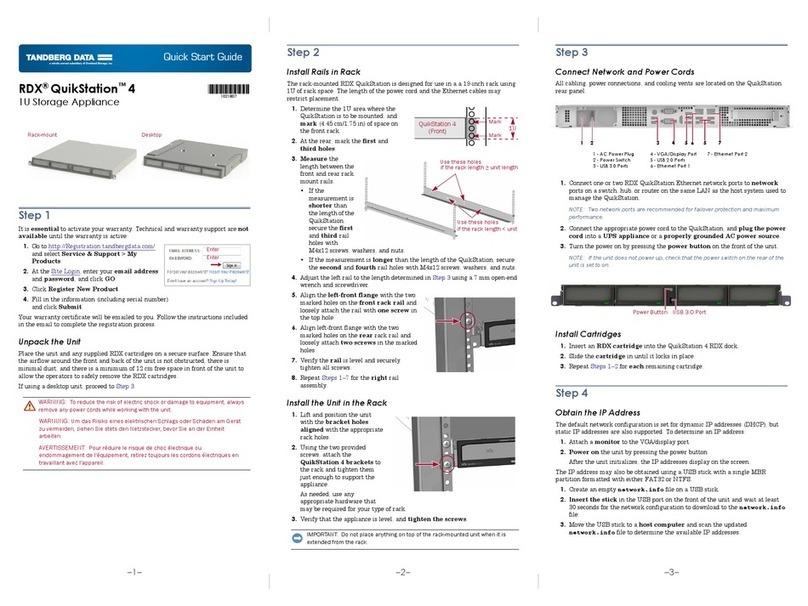

Tandberg Data RDX QuikStation 4 Operating and maintenance instructions

Tandberg Data

Tandberg Data MSERIES USER User manual

Tandberg Data

Tandberg Data SLR7-140 PROGRAMMER User manual

Tandberg Data

Tandberg Data SUPERLOADER User manual

Tandberg Data

Tandberg Data Magnum 224 User manual

Tandberg Data

Tandberg Data Autoloader Tandberg LTO2 User manual

Tandberg Data

Tandberg Data SLR User manual

Tandberg Data

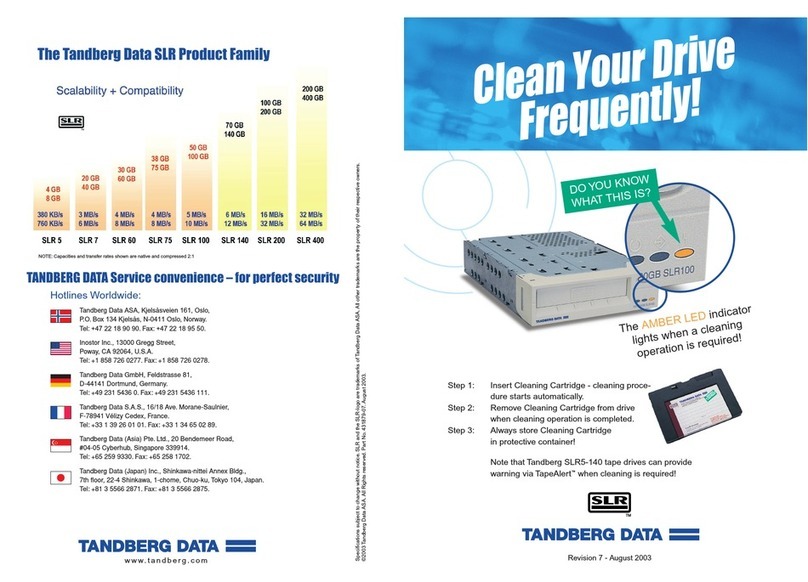

Tandberg Data Tape Backup System DLT4000 User manual

Popular Network Hardware manuals by other brands

Cisco

Cisco CGR 1000 Series Getting connected guide

Matrix Switch Corporation

Matrix Switch Corporation MSC-HD161DEL product manual

National Instruments

National Instruments NI 653x user manual

B&B Electronics

B&B Electronics ZXT9-IO-222R2 product manual

Yudor

Yudor YDS-16 user manual

D-Link

D-Link ShareCenter DNS-320L datasheet