1. SAFE WORK PRINCIPLES.

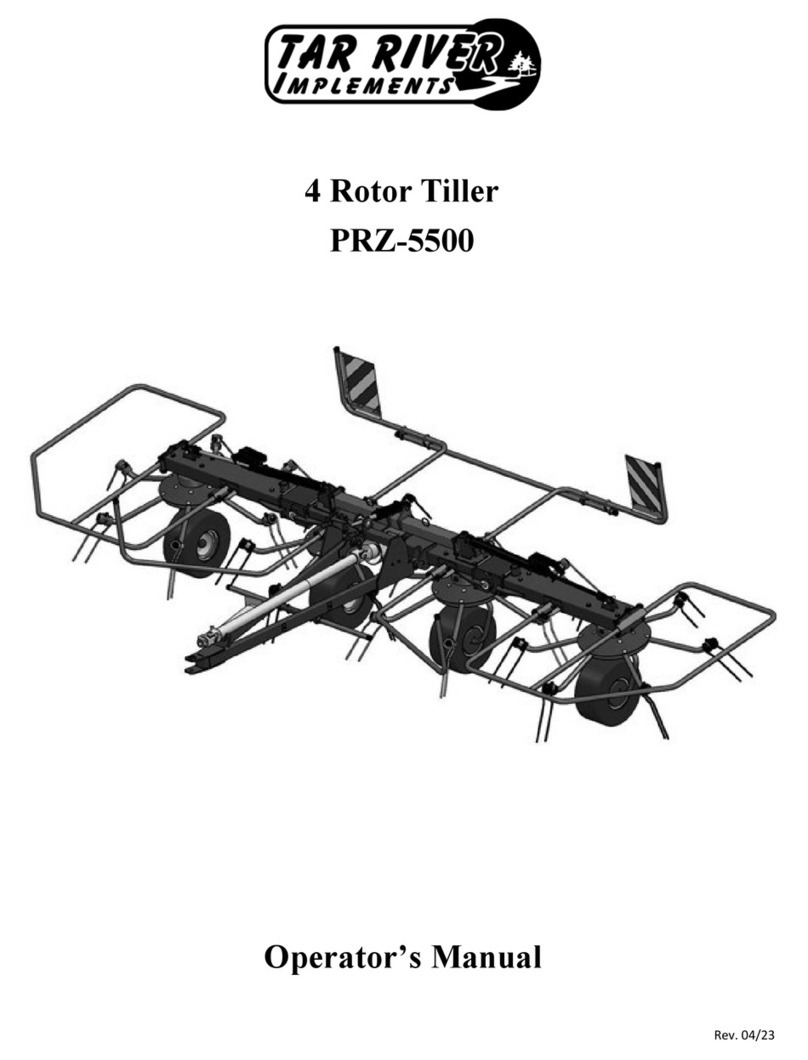

Operation of the rake tedder and preparing it to work as well as maintenance and repairs should be performed upon

prior familiarising with this instruction manual. During machine exploitation general occupational safety of work

rules and the following recommendations must be met:

1. The rake tedder can be operated by an adult person holding license allowing to operate agricultural tractors.

2. Operation of the machine by persons under influence of alcohol or other intoxicating substances is forbid-

den.

3. Warnings before hazardous places should be observed at starting the machine.

4. During preparation of the machine for work and at connecting and disconnecting it with the tractor special

attention must be kept.

5. After suspending the machine of the tractor - check the condition of pins and securing cotters and their cor-

rect placement. To secure all the pins included in the tractor-machine unit typical security cotters should be

used.

6. Prior to each starting up of the machine check if there are no bystanders nearby,

and children especially.

7. Check if all the mechanism guards and fixed correctly.

8. Operation without the drive guard is forbidden.

9. Check if the telescopic-articulated shaft is connected correctly with the WOM of the tractor and WPM

(power take off shaft) of the machine.

10. The agricultural tractor should have a functional power hydraulic and braking system.

11. The speed of drive should always be adapted to the conditions of the environment. Sharp turning should be

avoided at riding on mountains and in valleys and across hill slopes.

12. Machine inertia should be considered when driving in curves.

13. The permissible slope inclination for work and transport driving is 8.5°.

14. During transport on smooth roads do not exceed the speed of 25 km/h, and on field roads, curves and bumps

- up to 15 km/h, the end of the machine should be marked with a reflective triangle

and warning plates.

15. Check tightness of all the bolts and nuts after one hour of operation.

16. The machine should be lifted and lowered gently.

17. It is forbidden to use the machine, which demonstrates the signs of mechanical damage.

18. It is forbidden to work after raised elements of the machine.

19. Dysfunctions of the machine elements should be removed only with the tractor engine switched off and

with the ignition key removed.

20. The raking device is protected with guards, but its resilient tines protrude outside the guards, therefore, get-

ting close to their range during operation is forbidden and results in hazards.

21. Prior to each starting up of the agricultural tractor and switching on the machine mechanisms, a warning

signal must be sounded for the persons nearby.

22.During a break in work or longer stoppage the machine should be left and the engine stopped.

23. Prior to leaving the tractor stop the engine and take of the ignition key. Engage the hand brake and secure

the machine.

24. Nobody can stay between the tractor and the machine before the tractor engine is put off.

25. Transport of persons on the machine construction is forbidden.

26. After work the tool cannot be left on the place, in which it could cause injuries of people or animals.

27. The rake tedder disconnected from the tractor should be supported and the brake of the supporting wheel

should be engaged.