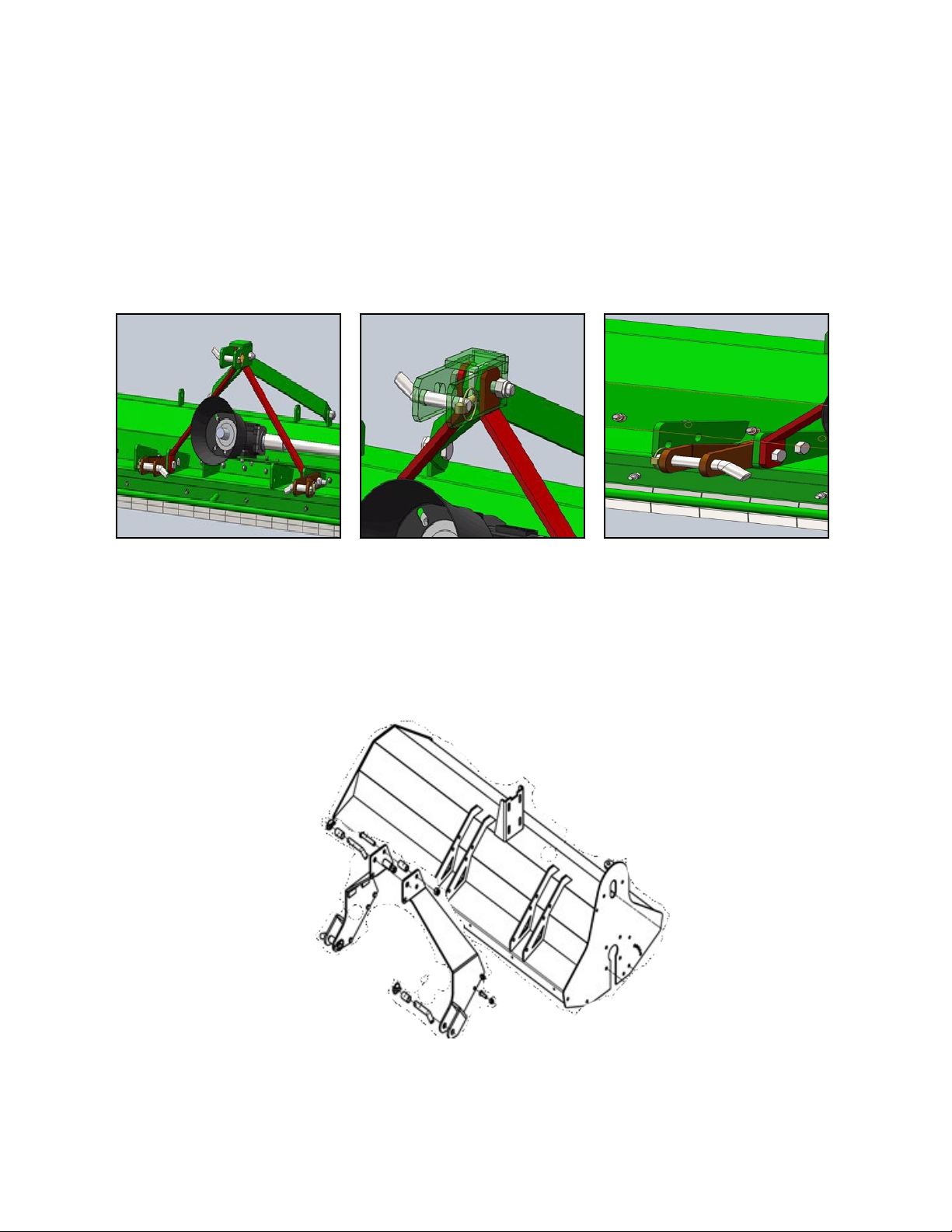

ATTACHMENT TO THE TRACTOR

Carefully read this instruction manual and the manuals of the tractor to ensure all safety pre-

cautions are taken . All mowers are built to be attached to any tractor equipped with a three-point lift

of the correct category and with suitable ball ends.

Before attaching the equipment to the tractor, make sure that the ground is smooth and flat and

that nobody is standing between the tractor and the mower; slowly move the tractor towards the mow-

er by aligning the tractor lifter arms with the two mower coupling side pins; turn the engine off and

pull the brake.

Connect the tractor top link to the third upper point by removing the pin located between the

two plates, inserting the top link and securing it by means of the pin.

Adjust the top link so that the upper part of the frame is parallel to the ground.

Block all the linking parts by means of the sway chains or arms.

•

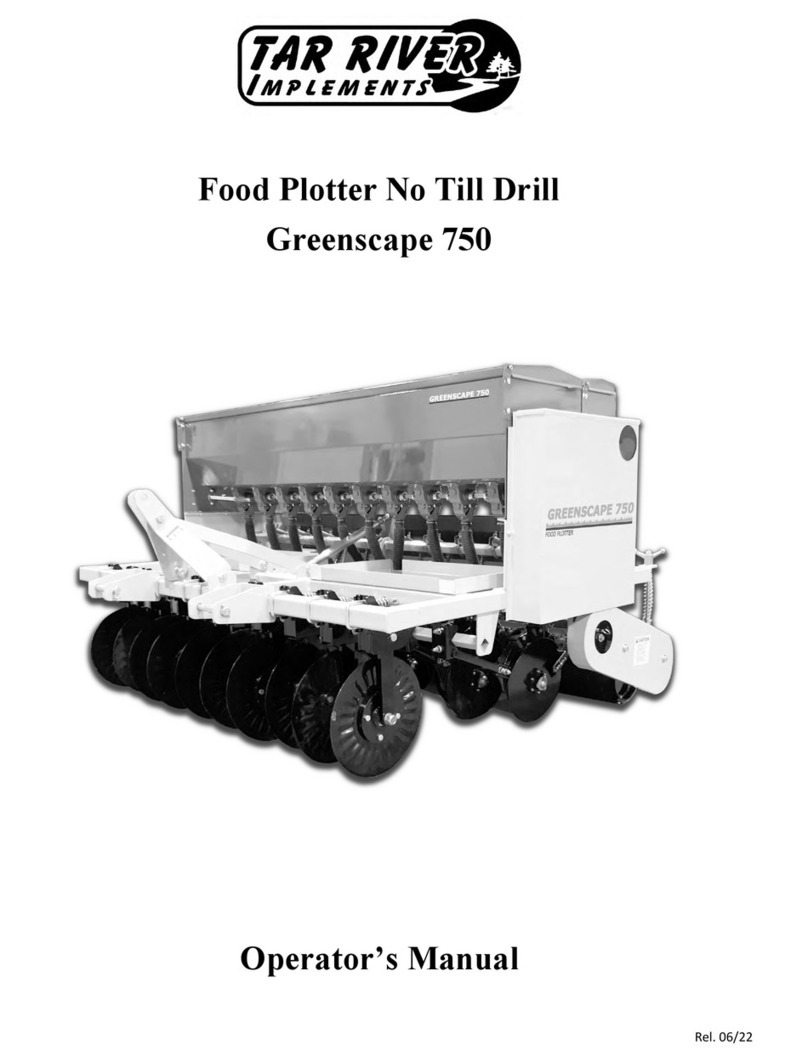

Connect Hydraulic Quick Connect Couplings to Tractor.

•

Remove Locking Pivot Pin.

•

Remove Locking Angling Pin.

•

Adjust Hydraulic flow Control.

Before installing the PTO shaft make sure that the RPM rating and the direction of rotation

match those of the tractor. Carefully read the PTO shaft and tractor instructions.

Furthermore, accurately read the instructions of the manufacturer of the PTO shaft and of the tractor.

Before starting any activity, make sure that the guards are installed on the power take off of the tractor

and PTO shaft. Make sure that they cover the PTO shaft throughout its length.

Shortening a PTO Driveline

1. With the implement attached to the tractor’s three point

hitch, and the PTO driveline not installed, separate the

PTO driveline. Attach the implement end to the imple-

ment and the other end to the tractor PTO input shaft.

2. Raise the implement by using the tractor’s hydraulic 3-

point hitch to it’s maximum lift height.

3. Hold the half shafts next to each other and mark them so

each end is approximately ½” from hitting the end of the

telescopic profiles.

4. Shorten the inner and out guard tubes equally.

5. Shorten the inner and outer profiles by the same length as

the guard tubes. Using a rattail file, round off all sharp

edges and burrs. Grease the telescopic profile generously

before reassembling.

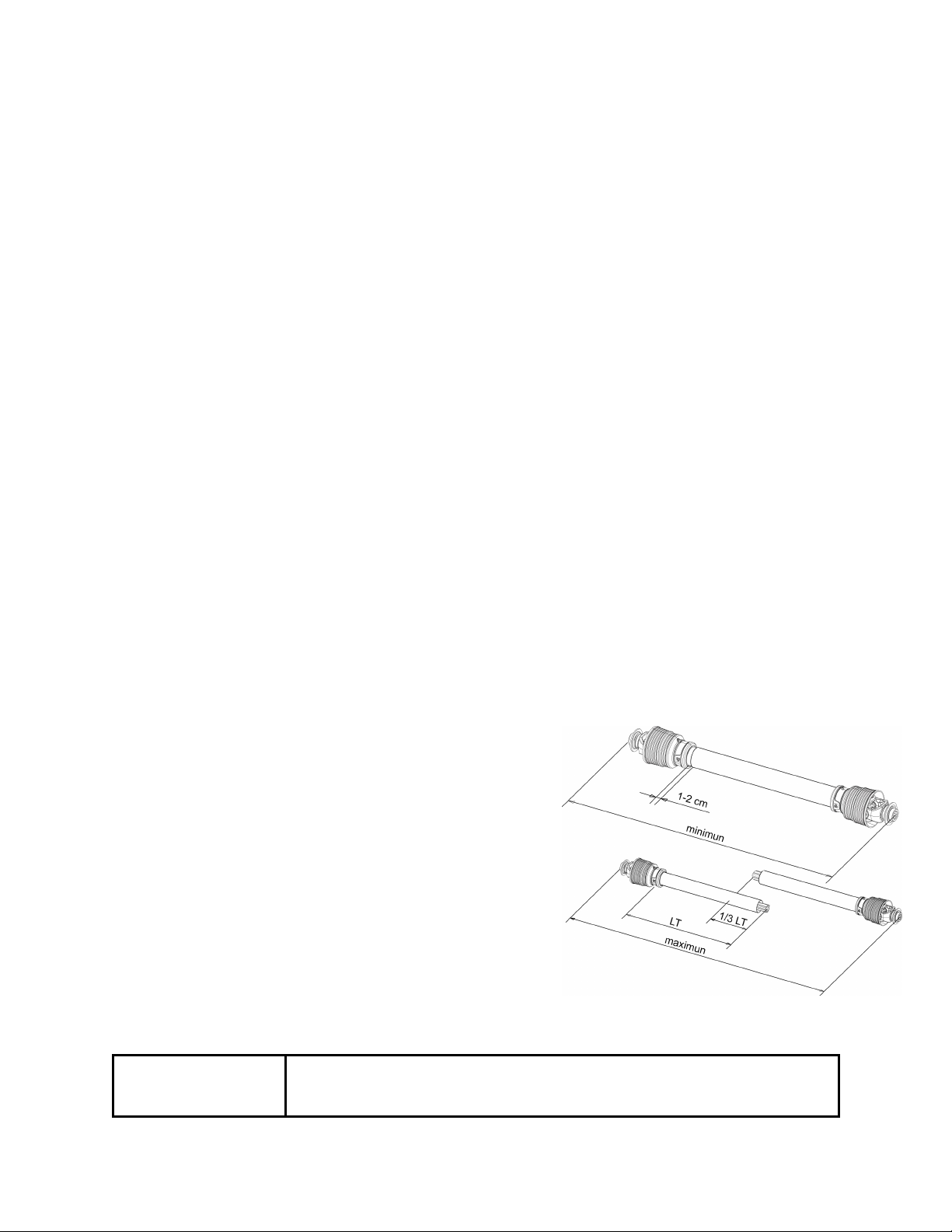

CAUTION When fully extended, the plastic pipes must overlap by at

least 1/3 of the length of the pipes (LT). When retracted, the

min. acceptable clearance is 1-2 cm.