tatsuno ULTRA FN-1025 Series Instructions for use

UP051-EN Nozzle FN-1025 - Instruction and Maintenance Manual_rev2.docx

TATSUNO ULTRA Automatic Nozzle

for Vapour Recovery Fuel Dispenser

Nozzle Model: FN-1025 series

Instruction and Maintenance Manual

II 1 G

TATSUNO ULTRA automatic nozzle for vapour recovery without swivel

TATSUNO ULTRA automatic nozzle for vapour recovery with double swivel (FJ-1043)

UP051-EN Nozzle FN-1025 - Instruction and Maintenance Manual_rev2.docx

The following definitions and symbols are used in this manual.

DANGER The hazard or unsafe practice will result in severe injury or death.

WA R N I N G The hazard or unsafe practice could result in severe injury or death.

CAUTION The hazard or unsafe practice could result in minor injury.

Marks representing "caution/ban/instruction"

The triangle ( ) mark alerts caution.

The point of caution is shown inside the triangle (caution to electric

shown in this example).

A general caution is indicated by

The circle () mark shows banning.

What is banned is shown inside the circle (no fire in this example).

A general ban is indicated by .

The black spot (

) indicates an instruction.

The actual action is shown inside (the example shows turn off the power).

A general instruction is indicated by

WARNING

Read the Instruction Manual carefully before work.

In particular, the "HINTS AND TIPS FOR SAFE USE" explains important matters for preventing

casualties and damages of properties. Please read and understand perfectly.

If the Instruction Manual is not legible or lost, please call TATSUNO or the local TATSUNO agent.

DEFINITIONS AND SYMBOLS

UP051-EN Nozzle FN-1025 - Instruction and Maintenance Manual_rev2.docx

Observe the following cautions.

DANGER

1. Never use flame in the filling station.

A lit cigarette of a customer or other flame may ignite to cause fire.

2. Stop engine while fuelling.

Stop engine before starting fuelling.

Don't start up engine until fuelling port cap is tightened.

Sparks from the electric system of the vehicle or ignition from overheated

muffler may cause fire.

WARNING

1. Discharge your static electricity before refuelling.

Failure to discharge may ignite gasoline vapours.

2. Turn off cell phones and other electronic devices.

Electronic devices may ignite gasoline vapours.

3. Never pull nozzle lever except when refuelling.

Never pull nozzle lever unless the nozzle is inserted in the fuelling port.

If nozzle lever is pulled by mistake, oil pours out.

4. Contact the nozzle spout to fuelling port and insert the

nozzle spout deeply.

The static electricity may be generated while refuelling.

This will discharge static electricity from the nozzle by contacting the

nozzle spout to fuelling port.

Static electricity generated during refuelling may ignite gasoline vapours.

If the nozzle is not inserted deeply enough, it may drop out while refuelling

to cause fire or disaster.

HINTS AND TIPS FOR SAFE USE

UP051-EN Nozzle FN-1025 - Instruction and Maintenance Manual_rev2.docx

5. Don't leave the place while refuelling.

If the automatic shut off mechanism doesn't work due to mechanical trouble,

fuel overflows to cause fire.

Stop pump immediately if oil overflows.

It is required to attend while refuelling by the fire regulation.

6. Don't fuel to another container than specified.

Do not fuel gasoline into nonconductive plastic container or the like.

When contained in a plastic container, it may cause fire due to static

electricity.

7. Return nozzle lever securely.

After fuelling completely, return the nozzle lever fully to the initial position.

Otherwise, fuel may pour out when starting next operation.

8. Tighten fuelling cap.

After completion of fuelling, tighten fuelling cap securely.

Or the fuel may escape through loose cap while driving to cause slip

accident or fire.

9. Set the nozzle in the right direction.

Automatic shut off function of the nozzle may not work properly if

refuelling with the sideways or the inverse attitude.

10. Do not allow children to pump gasoline.

Keep children away from the dispenser area.

HINTS AND TIPS FOR SAFE USE

UP051-EN Nozzle FN-1025 - Instruction and Maintenance Manual_rev2.docx

WARNING

If fuel leaks or ignites, do the following.

If fuel leaks...

Stop pump immediately.

Move the customers to safe place.

Sprinkle dry sand or the like over the leaking fuel to prevent diffusion.

Keep fire extinguisher at hand to be ready for fire.

Prevent entr

y

of vehicles and people to prevent secondar

y

disaster.

If oil ignites...

Move the customers to safe place.

Call local fire department immediately.

Extinguish fire as far as possible.

HINTS AND TIPS FOR SAFE USE

UP051-EN Nozzle FN-1025 - Instruction and Maintenance Manual_rev2.docx

1. Specification..……………………………………………………………………1

2. Instruction….……………………………………………………………………2

2-1. How to use nozzle……………………………………………………………………………2

2-2. Installation……………………………………………………………………………………3

2-3. Testing….……………………………………………………………………………………4

3. Maintenance..……………………………………………………………………5

3-1. Daily inspection…...…………………………………………………………………………5

3-2. Periodic inspections………………………………………….………………………………5

4. Trouble Shooting…………………………………………………………………6

5. Guarantee and Replacement Period……………………………………………7

5-1. Guarantee…………...………………………………………………………………………7

5-2. Replacement period...……………………………………….………………………………7

CONTENTS

UP051-EN Nozzle FN-1025 - Instruction and Maintenance Manual_rev2.docx

- 1 -

TATSUNO ULTRA automatic nozzles with vapour recovery are designed for use on fuel dispensers for the

'active' vapour recovery up to 45L/min flow rate.

The TATSUNO ULTRA automatic nozzle with vapour recovery fulfils European Standard EN 13012, and each

nozzle has been subjected to stringent tests before leaving the factory.

Specification

Nozzle Model FN-1025

Fuel type used Petrol

Spout O.D. 21mm

Vapour inlet type (1) Rubber suction inlet

(2) Stainless suction inlet

Vapour recovery valve (1) On/Off vapour valve

(2) Proportional vapour valve with regulating screw

Flow range 2L/min up to 45L/min

Maximum working pressure 0.49MPa

Temperature range -20℃up to +50℃

Viscosity range 0.3mPa.s up to 6mPa.s

Pressure-controlled safety shut-off

mechanism for prepay/pre-set dispensers Applicable

Double swivel (FJ-1043) Option

Hose Inlet M34х1.5 female

1. S

p

ecification

UP051-EN Nozzle FN-1025 - Instruction and Maintenance Manual_rev2.docx

- 2 -

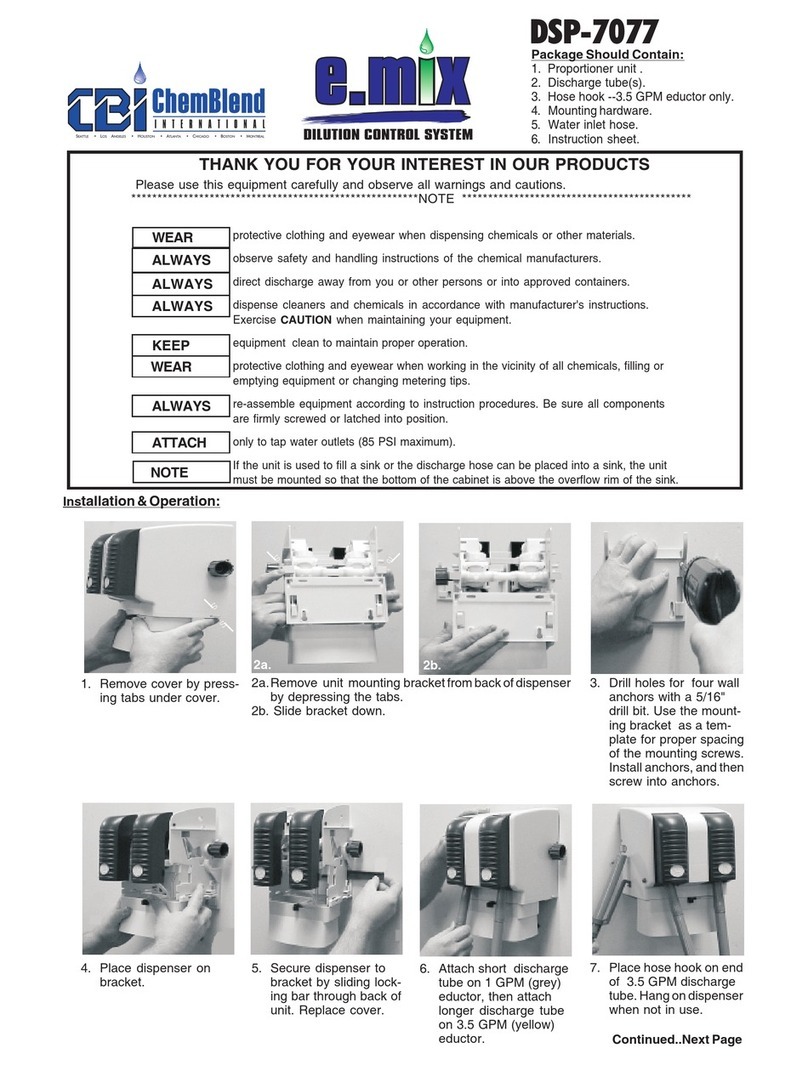

2-1. How to use nozzle

1. Insert the nozzle sufficiently into the fuelling port of the automobile and seal up vapour recovery boot

with the fuelling port.

2. Pull the nozzle lever and lock in the latch. Fuelling starts.

3. When the fuel level reaches the pilot hole of the nozzle spout, the main valve of the nozzle closes

automatically to stop fuelling.

4. Unlock the nozzle lever from the latch and return to the initial state. It can refuel again if pulling the lever

once again.

WARNING

1. Do not drop the nozzle onto the ground. The nozzle may be damaged

and automatic shut off function of the nozzle may not work.

2. Insert the nozzle deeply into the fuelling port. Otherwise, the nozzle

may drop by the shock of automatic shut-off.

3. Depending on the car model, the fuel may pour out before the auto-stop

is applied due to difference in the fuelling port. In such a case, set the

nozzle lever to the lower position, and slow down the fuelling speed.

4. Set the nozzle in the right direction. Automatic shut off function of the

nozzle may not work properly if refuelling with the sideways or the

inverse attitude.

Spout Lever

LatchAnchor Spring

Lower position First position

2. Instruction

UP051-EN Nozzle FN-1025 - Instruction and Maintenance Manual_rev2.docx

- 3 -

2-2. Installation

1. Shut off power to the dispenser before starting the nozzle & swivel installation or replacement. Relieve

system pressure before servicing or replacing.

2. Carefully drain fuel from hose & nozzle & swivel into approved container in the case of replacing nozzles.

3. If nozzle & swivel replacement, Replace the O-ring of the hose side with new.

The tightening torque of the screw: 60N.m.

4. Flow test nozzles & swivels before putting nozzles & swivels in service.

See testing instructions. (Reference page 4)

WARNING

1. Please read safety instructions "HINTS AND TIPS FOR SAFE USE" completely before installing and

replacing nozzles.

2. Discharge your static electricity before installing.

Static electricity may ignite gasoline vapours.

3. Not to mix rubbishes into the nozzle when installing and replacing

nozzles. This could result in foreign material in the nozzle’s main valve

and cause the nozzle to not shut off.

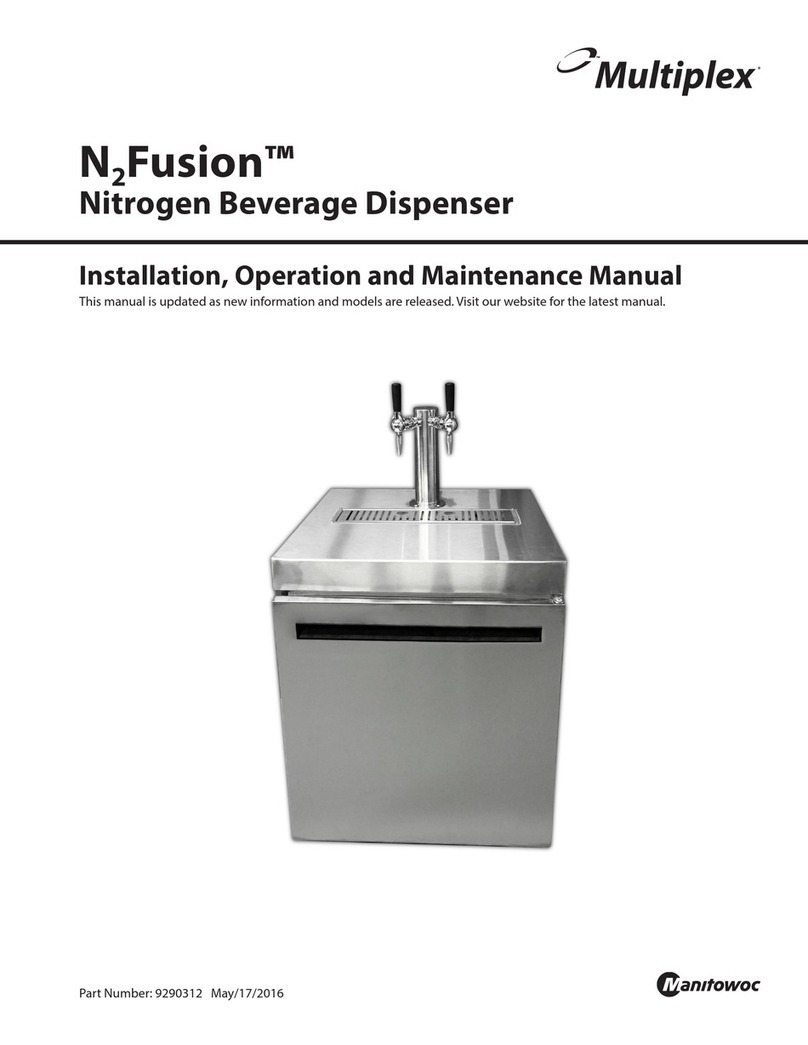

Without Double Swivel

With Double Swivel

UP051-EN Nozzle FN-1025 - Instruction and Maintenance Manual_rev2.docx

- 4 -

2-3. Testing

Each nozzle & swivel should be tested after installing and replacing.

Necessary facilities

Approved metal test container (please obey the local laws and regulations)

Ground wire

Insulation resistance tester

Stopwatch.

Deal with static electricity before flow test.

Confirm that the electrical resistance between the nozzle tip and dispenser main ground terminal is less

than 1MΩ. (Note: electrical resistance between of any point of spout to coupling should be ≤0.1MΩ)

Ground the approved metal test container and the nozzle with ground wires.

Discharge static electricity in the human body.

Flow test

1. Leak confirmation

Start pump, and check for leaks between the nozzle & swivel and hose connections.

2. Flow rate test

Measure the flow rate of the nozzle first latch position.

Insure the maximum flow rate is below the maximum flow rate of the dispenser.

3. Automatic shut off test

Start flow into approved metal test container; place nozzle in first latch position.

Immerse the sensor on nozzle spout tip below the level of liquid.

Nozzle must shut off immediately.

Repeat procedure for nozzle low latch position.

Repeat the procedure above three times at nozzle all latch position.

4. Pressure-controlled safety shut-off test

Pre-set refuelling quantity (more than 5L) to dispenser.

Start flow into approved metal test container in the nozzle fully open position.

Confirm that flow is stopped with quantity of pre-set refuelling.

Stop pump.

Grasp nozzle lever to fully opening position; restart pump.

Confirm that there shall be no fuel flow.

Repeat the procedure above three times.

Vapor recovery test

Perform the vapor recovery test according to local law.

WARNING

1. Please read safety instructions "HINTS AND TIPS FOR SAFE USE" completely before installing and

replacing nozzles.

2. Ground the approved metal test container and the nozzle surely.

Discharge the static electricity in the human body.

Static electricity may ignite gasoline vapours.

UP051-EN Nozzle FN-1025 - Instruction and Maintenance Manual_rev2.docx

- 5 -

3-1. Daily inspection

1. Confirm that the nozzle & swivel do not leak with normal visual acuity.

2. Confirm that the nozzle & swivel have not deformation or other damages.

3. Inspect the vapour recovery boots, scarves, grip covers, and confirm that there are not damages and intense

dirt. Replace there as necessary.

3-2. Periodic inspection

(less than six months after installation)

1. Starts pump and confirm that the nozzle & swivel do not leak.

2. Confirm the automatic shut off function of the nozzle (first and low latch position) according to “Testing

of 2.3”.

3. Confirm the pressure-controlled safety shut-off function of the nozzle according to “Testing of 2.3”.

4. Confirm that the electrical resistance between the nozzle tip and dispenser main ground terminal is less

than 1MΩ.

5. Confirm that the nozzle & swivel have not deformation or other damages.

6. Inspect the vapour recovery boots, scarves, grip covers, and confirm that there are not damages and

intense dirt. Carry out replacement if abnormality is discovered.

WARNING

1. Please read safety instructions "HINTS AND TIPS FOR SAFE USE" completely before inspecting.

2. Ground the approved metal test container and the nozzle surely.

Discharge the static electricity in the human body.

Static electricity may ignite gasoline vapours.

Vapour Recovery Boot Scarf Grip Cover

3. Maintenance

UP051-EN Nozzle FN-1025 - Instruction and Maintenance Manual_rev2.docx

- 6 -

Problem Solution

Nozzle keeps tripping off immediately. 1. The sensor or the air passage on the nozzle spout may be

blocked by an alien substance or fuel. Remove the alien

substance or fuel and fill again.

2. The safety cut out attitude valve may operate with some

near horizontal fill pipes. Turn the nozzle spout downward

and fill again.

3. Some filler necks are difficult to refuel.

Slow down fuel delivery. Put on low latch position.

Nozzle fails to open. 1. Pump pressure is not added to the nozzle. Check the pump

and solenoid valve.

2. The passage in the nozzle is clogged up.

Replace or clean the nozzle.

3. Confirm whether nozzle lever was damaged.

In the case of damage, change the lever.

Nozzle does not close automatically Stop use promptly.

Call your service contractor for repair or replace the nozzle.

Nozzle leaks.

Stop use promptly.

Call your service contractor for repair or replace the nozzle.

4. Trouble Shooting

UP051-EN Nozzle FN-1025 - Instruction and Maintenance Manual_rev2.docx

- 7 -

5-1. Warranty period

TATSUNO guarantees against defective materials and manufacturing during warranty period.

Warranty period: One year from date of supply.

If the delivery date cannot be established, the date code on the nozzle prevails.

Warranty does not cover below.

(1) Damage to the nozzle & swivel in an accident etc.

(2) Damage by natural disasters, such as a typhoon and an earthquake.

(3) Wear items such as spouts, vapour recovery boots, scarves or grip covers.

5-2. Replacement period

Nozzles are expendables. Even if there is no abnormality, we recommend replacement after use of the

nozzle & swivel for three years or the quantity of refuelling 2,500,000L.

If you have any suggestions as to how we can improve the quality and/or

readability of this manual, then we would be happy to hear from you. We

can be contacted at the following address:

International Marketing Department

TATSUNO CORPORATION

1-1, Kasama 4-Chome, Sakae-ku, Yokohama-shi, Kanagawa

Japan

FAX : 81-45-893-4680

No part of this manual may be copied or reproduced in any form or by any

means without prior written consent of TATSUNO CORPORATION. The

information in this manual is subject to change without notice and should

not be construed as a commitment by TATSUNO CORPORATION.

TATSUNO CORPORATION has taken great effort to verify the accuracy

of this manual but assumes no responsibility for any technical inaccuracies

or typographical errors.

© TATSUNO CORPORATION. All rights reserved.

Suggestions

5. Guarantee and Replacement Period

Table of contents

Other tatsuno Dispenser manuals