tau K206MA User manual

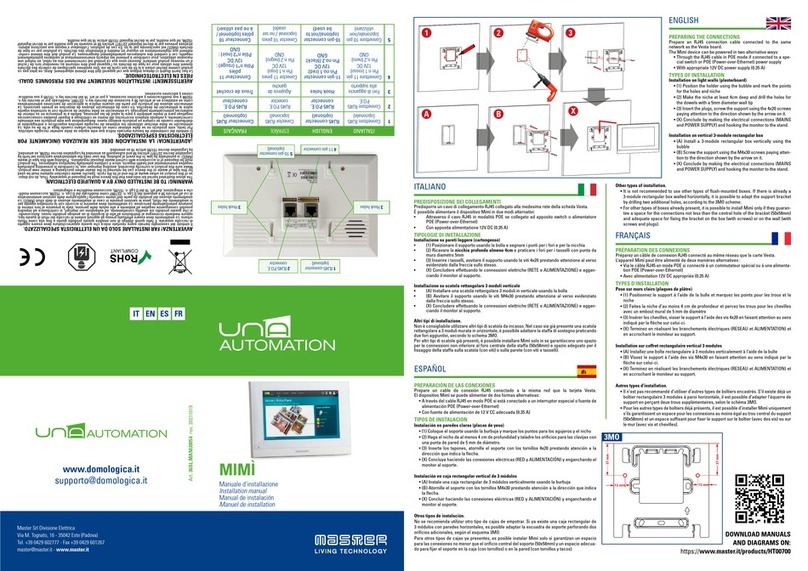

GUIDA ALL’INSTALLAZIONE

INSTALLATION GUIDE

INSTALLATIONSANLEITUNG

NOTICE D’INSTALLATION

GUÍA PARA LA INSTALACIÓN

GUIA DE INSTALAÇÃO

IT - Istruzioni originali

K206MA

K206MA

D-MNL0K206MA 20-01-2023- Rev.28 Ver. Firmware 9.01

2

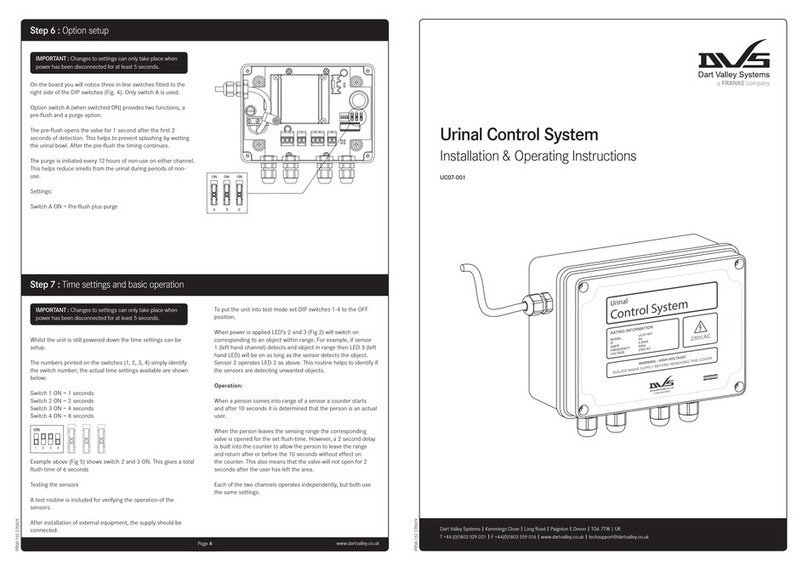

TRA

FR

TCA

CH2

PROG

CH1

F4

16A

F3

3.15A

F5

10A

DL6

DL5

DL4

DL3

DL2

DL1

DL8

DL7

1 2 3 4 5 6 7 8 9 10 11 12

K206MA

DL6

DL5

DL4

DL3

DL2

DL1

DL8

FIXED SAFETY EDGE

PHOTO

CLOSE

STOP

OPEN/CLOSE

OPEN

ERRORS

DL7 BATT

TCA

+-

FR

+-

+-

1 2 3 4 5 6 7

8 9 10 11 12

Dip-switchesON

FS1

TRASF

FS2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23242526272829303132

Flashing

light

18V DC

max. 20W

Open/Close

- 0 V

+ 18 V

- 0 V

+ 18 V

- 0 V

Stop

Common

Common

Open

Close

Vandal-proof

2nd radio

channel

Fixed safety edge

- 0 V

+ 18 V

- 0 V

Photocell (N.C.)

Common

Photocells

RX

12345

TX

1 2

-

+

M

+5V

ENC

GND

Bar Led (White)

J6

NOT

USED

Aerial

BATT

-

+

-

+

Stop Swing away system switch (optional)

- Photovoltaic system input

+ Photovoltaic system input

or

LUXE

LUXE-M

23242526272829303132

M

+5V

ENC

GND

-

+

RBLO

J3

J4

Trimmer:

SCHEMA CABLAGGIO K206MA / K206MA WIRING DIAGRAM / SCHALTPLAN DER K206MA

3

TRA

FR

TCA

CH2

PROG

CH1

F4

16A

F3

3.15A

F5

10A

DL6

DL5

DL4

DL3

DL2

DL1

DL8

DL7

1 2 3 4 5 6 7 8 9 10 11 12

K206MA

DL6

DL5

DL4

DL3

DL2

DL1

DL8

FIXED SAFETY EDGE

PHOTO

CLOSE

STOP

OPEN/CLOSE

OPEN

ERRORS

DL7 BATT

TCA

+-

FR

+-

+-

1 2 3 4 5 6 7 8

9 10 11 12

Dip-switchesON

FS1

TRASF

FS2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23242526272829303132

Flashing

light

18V DC

max. 20W

Open/Close

- 0 V

+ 18 V

- 0 V

+ 18 V

- 0 V

Stop

Common

Common

Open

Close

Vandal-proof

2nd radio

channel

Fixed safety edge

- 0 V

+ 18 V

- 0 V

Photocell (N.C.)

Common

Photocells

RX

12345

TX

1 2

-

+

M

+5V

ENC

GND

Bar Led (White)

J6

NOT

USED

Aerial

BATT

-

+

-

+

Stop Swing away system switch (optional)

- Photovoltaic system input

+ Photovoltaic system input

or

LUXE

LUXE-M

23242526272829303132

M

+5V

ENC

GND

-

+

RBLO

J3

J4

Trimmer:

SCHÉMA CÂBLAGE K206MA / ESQUEMA DEL CABLEADO K206MA / ESQUEMA DE LIGAÇÕES K206MA

- Morsetti 1 - 2: Attenzione a NON invertire la polarità.

- Se il jumper 6 non è inserito, verrà attivata la modalità basso consumo e, al termine

di ogni manovra, le uscite 11-12, 12-13, 14-15, 16-17 e 16-18 verranno spente.

- Terminals 1 – 2: Careful NOT to invert polarity.

- If Jumper 6 is not plugged in, energy saving mode will be activated and, at the end

of each manouvre, outputs 11-12, 12-13, 14-15, 16-17 and 16-18 will be switched o.

- Klemmen 1 - 2: Achtung: Nicht verpolen.

- Wenn der Jumper 6 nicht eingesteckt ist, wird die Modalität Energiespar aktiviert und am

Ende jedes Manövers werden die Ausgänge 11-12, 12-13, 14-15, 16-17 und 16-18 abgeschaltet.

- Etaux 1 - 2: Assurez-vous de NE PAS inverser la polarité.

- Si el puente 6 no está insertado, se activará el modo de bajo consumo y, al nal de cada

maniobra, las salidas 11-12 , 12-13 , 14-15 , 16-17 y 16-18 se desconectarán.

- Bornes 1 - 2: Tenga cuidado en NO invertir la polaridad.

- Si le cavalier J6 n’est pas inséré, la fonction modalité consommation réduite sera activée et,

à la n de chaque manœuvre, les sorties 11-12, 12-13, 14-15, 16-17 e 16-18 seront désactivées.

- Terminais 1 – 2: Cuidado NÂO inverter a polaridade.

- Se o jumper J6 não está conectado, ele irá alternar para o modo de baixo consumo de ener-

gia e, ao nal de cada manobra, as saídas 11-12, 12-13, 14-15, 16-17 e 16-18 serão desligados.

15

WARNINGS

This manual is designed to assist qualied installation personnel only. It contains no information that may be

of interest to nal users. This manual is attached to the K206MA control unit mounted on the LUXE or RBLO(X)

automatic bar, therefore it may not be used for dierent products!

Important warnings:

Disconnect the mains power supply to the board before accessing it.

The K206MA control unit is suitable for the control of a direct-current electromechanical gearmotor for the

automation of sliding gates.

Any other use is considered improper and is consequently forbidden by current laws.

Please note that the automation system you are going to install is classi ed as “machine construction” and

therefore is included in the application of European directive 2006/42/EC (Machinery Directive).

This directive includes the following prescriptions:

- Only trained and qualied personnel should install the equipment;

- the installer must rst make a “risk analysis” of the machine;

- the equipment must be installed in a correct and workmanlike manner in compliance with all the standards

concerned;

- after installation, the machine owner must be given the “declaration of conformity”.

This product may only be installed and serviced by qualied personnel in compliance with current, laws, regula-

tions and directives.

When designing its products, TAU observes all applicable standards (please see the attached declaration of

conformity) but it is of paramount importance that installers strictly observe the same standards when installing

the system.

Unqualied personnel or those who are unaware of the standards applicable to the “automatic gates and

doors” category may not install systems under any circumstances.

Whoever ignores such standards shall be held responsible for any damage caused by the system!

Do not install the unit before you have read all the instructions.

INSTALLATION

Before proceeding, make sure that the mechanical part is working perfectly and that the boom has been

properly balanced.

Note: it is compulsory to earth the system and to observe the safety regulations that are in force in

each country.

CAUTION:

- do not use single-wire cables (single conductor), eg. intercom ones, in order to avoid interruptions on

the line and false contacts;

- do not reuse old pre-existing cables.

IF THESE ABOVE INSTRUCTIONS ARE NOT FOLLOWED IT COULD PREJUDICE THE PROPER WORKING ORDER

OF THE EQUIPMENT AND CREATE HAZARDOUS SITUATIONS FOR PEOPLE. FOR THIS REASON THE “MANUFAC-

TURER” DECLINES ALL RESPONSIBILITY FOR ANY MALFUNCTIONING AND DAMAGES THUS RESULTING.

1. CONTROL PANEL FOR AUTOMATIC BARS

• LOGICS WITH MICROPROCESSOR

• STATUS OF INPUTS SIGNALLED BY LEDs

• INCORPORATED FLASHING CIRCUIT

• ENCODER SENSOR FOR SELF-LEARNING OF TRAVEL

• 433.92 MHz 2 CHANNEL BUILT-IN RADIO RECEIVER (CH)

• BATTERY CHARGER BOARD (INTEGRATED)

• BATTERY CONNECTOR

• DIAGNOSTICS OF MALFUNCTIONS SIGNALLED BY LED

• POSSIBILITY OF ENERGY SAVING OPERATION

• COMPATIBILITY WITH OUR APPS: TAUOPEN AND TAUAPP

ATTENTION:

- do not use single cables (with one single wire), ex. telephone cables, in order to avoid breakdowns

of the line and false contacts;

ENGLISH

16

- do not re-use old pre-existing cables;

2. INTRODUCTION

The K206MA board has two working modes, selectable through the J6 jumper (see wiring diagram).

J6 Jumped: standard mode, i.e. the control unit is powered all the time;

J6 Not jumped: low-energy mode, i.e. the control unit is switched o after each operation and on

after each command (mode where power is supplied by other energy sources,

ex. batteries charged by a photovoltaic panel).

Once the connection is achieved, in low-energy mode, press the PROG button briey:

• All the green LEDs must be on (each of them corresponds to a Normally Closed input). The go o

only when the controls to which they are associated are operated. Except for the green led DL4,

which corresponds to CLOSE input (a Normally Open contact).

• All the red LEDs (and the green led DL4) must be o (each of them corresponds to a Normally Open

input). The light up only when the controls to which they are associated are operated.

3. TECHNICAL CHARACTERISTICS

Board power supply 13,5V AC - 50 Hz

Max. absorption DC motor 14 Ah - 18V DC

Fast acting fuse for protection of input power supply 13,5V AC (F4 - 5x20) F 16A

Fast acting fuse for battery charger protection (F5 - 5x20) F 10A

Fast acting fuse for protection of auxiliary circuits 18V DC (F3 - 5x20) F 3.15A

Motor power supply circuits voltage 18V DC

Auxiliary device circuits supply voltage 18V DC

Logic circuits supply voltages 5V DC

Operating temperature -20 °C ÷ +55 °C

4. CONNECTIONS TO TERMINAL BOARD

Terminals Function Description

FS1 - FS2 POWER

SUPPLY

13,5V AC control unit power supply input – Fed by the toroidal trans-

former and protected by the fuses on the 230V AC power supply.

1 - 2 AUX INPUT

external power input (ex. Photovoltaic system 12V DC).

NB: In the latest versions of the control boards, the voltage change

through jumper J7 is no longer necessary (make sure whether it is

present on the control board or not).

ATTENTION: POWERING THE CONTROL UNIT WITH AN EXTERNAL

SOURCE, ALL THE OTHER 18V DC OUTPUTS BECOME THE SAME AS THE

OUTSIDE VOLTAGE.

3 - 6 OPEN OPEN button N.O. input – Controls the total opening of the barrier.

(3= OPEN - 6= COM)

4 - 6 OPEN/CLOSE

OPEN/CLOSE button N.O. input – Controls the opening and closing of the

barrier and is regulated based on the function of dip-switches 2 and 4.

(4= O/C - 6= COM)

5 - 6 STOP

STOP button N.C. input – Stops the bar in any position, temporarily pre-

venting the automatic closure, if programmed. Bridge the connectors if

not used. (5= STOP - 6= COM )

7 - 8 CLOSE CLOSE button N.O. input – Controls the total closure of the barrier.

(7= COM - 8= CLOSE)

ENGLISH

17

7 - 9 PHOTOCELLS

N.C. photocell input - it cuts in during the closing. Bridge the connectors

if not used. (7= COM - 9= FOT)

Note: the photocell transmitter must always be supplied by termi-

nals no. 12 and no. 13, since the safety system test (phototest) is

carried out on it. Without this connection, the control unit does not

work. To override the testing of the safety system, or when the pho-

tocells are not used, set dip-switch no. 6 to OFF.

7 - 10 SENSITIVE

EDGE

SENSITIVE EDGE input (resistive sensitive edge or xed edge); It works only

during the closing phase and causes the total reopening of the boom.

Bridge the terminals if not used.

In case of an active automatic closing: After the rst intervention of the xed

edge and the consequent total opening, the boom will try an automatic

closing. If the CF contact is engaged again, the automation will reopen

up to the opening limit switch and temporarily disable the automatic

closing. It will return to normal operation only after the rst maneuver of

the automation, which requires a manual command. (7 = COMMON - 10

= SENSITIVE EDGE)

11 - 12 ** AUX auxiliary circuits output 18 V DC max. 15 W for photocells, receivers, etc...

(11= NEGATIVE - 12= POSITIVE)

12 - 13 ** TX PHOTOCELLS 18V DC output for transmitter photocell – phototest - max. no. 1 photocell

transmitters. (12 = POSITIVE - 13 = NEGATIVE)

14 - 15 **

FLASHING LIGHT

(LED CABINET

LUXE)

18V DC max. 20W output for ashing light supply, ashing signal sup-

plied by the control unit, rapid for closing, slow for opening. (14 = POSI-

TIVE - 15 = NEGATIVE)

16 - 17* ** ELECTROMAGNET

(VANDAL-PROOF)

Output for vandal-proof 18V DC, 3 W max;

Output for electromagnet to be connected to the end of the rod to hold

the barrier closed (vandal-resistant device). With the barrier closed, the

electromagnet is constantly powered. Every time a command is given,

the electromagnet is turned o before the motor starts running. (16=

POSITIVE - 17= NEGATIVE)

16 - 18* ** BAR LED (WHITE) bar LED power output. (16=POSITIVE - 18= NEGATIVE). See instructions

LA4/8 LARG 4/8

19 - 20* 2nd CH RADIO

2nd radio channel output - for control of an additional automation or for

switching on lights, etc... (N.O. clean contact)

Warning: to connect other devices to the 2nd Radio Channel (area

lighting, pumps, etc.), use an additional auxiliary relay (see note at

end of paragraph).

WARNING: the default outlet is active monostable 2 sec. To switch it

to active bistable or to modify the activation time it is necessary to

use the TAUPROG hand-held programmer (see relative instructions).

21 - 22 AERIAL plug-in radio-receiver aerial input , for 433.92 MHz receivers only. (21 =

GROUND - 22 = SIGNAL)

23 - 24 -

28 - 29 MOTOR motor supply output 18V DC max. 50 W.

(23-28 = POSITIVE - 24-29 = NEGATIVE). See note below.

25 - 26 - 27 OPTIONAL

ENCODER

encoder supply and input (25 = WHITE signal - 26 = BLUE negative - 27 =

BROWN positive). See note below.

30 - 31 - 32 MAIN

ENCODER

encoder supply and input (30 = WHITE signal - 31 = BLUE negative - 32 =

BROWN positive).

* The outlets can be congured using the TAUPROG (see relative instructions). The standard congu-

ration is shown in the table.

** If Jumper 6 is not plugged in, energy saving mode will be activated and, at the end of each

manouvre, outputs 11-12, 12-13, 14-15, 16-17 and 16-18 will be switched o.

ENGLISH

18

Terminals 23-24 must be used in parallel to 28-29 in the case of LUXE automatic barriers

(you have to observe the same polarity between the 2 outputs).

Terminals 25-26-27 are available if the circuit present on the K206MA relative to the en-

coder, terminals 30-31-32, is faulty

IMPORTANT:

• Do not connect auxiliary relays or other devices tot he 18 V DC output (terminals 11 – 12) to

avoid malfunctions of the control unit. Use separated power supply / transformers instead;

• do not connect switching feeders or similar apparatus close to the barrier that may be a

source of disturbance;

5. LOGIC ADJUSTMENTS

Make the logic adjustments.

Note: when any adjusting devices (trimmers or dip-switches) on the control panel are operated,

a complete manoeuvre must be carried out in order for the new settings to take eect.

TRIMMER

T.R.A. not used;

T.C.A. Automatic Closing time adjustment: from about 0,1 to 12 seconds (see dip-switch no. 1);

FR. obstacle detection sensitivity adjustment.

Note: by rotating the TRIMMER FR. clockwise the sensitivity of the gearmotor

to obstacles diminishes and therefore the thrust force increases; vice-versa, by

rotating it counter-clockwise, the sensitivity of the gearmotor to obstacles

increases and therefore the thrust force diminishes.

Dip switch

1AUTOMATIC

CLOSING

On when completely open, closure is automatic after the set time on the

T.C.A. trimmer has past.

O the closing manoeuvre requires a manual command.

22 / 4 STROKE

On when the automation is operating, a sequence of opening/closing com-

mands causes the bar to OPEN-CLOSE-OPEN-CLOSE, etc.

O

in the same conditions, the same sequence of commands causes the

bar to OPEN-STOP-CLOSE-STOP-OPEN-STOP, etc . (step-by step function)

(see also dip switch 4).

3

CLOSES AGAIN

AFTER THE

PHOTOCELL

On after the photocell is activated (input 7 - 9), the automation closes au-

tomatically after 1 seconds.

O function o.

4NO REVERSE On the automation ignores the closure command during opening and auto-

close time.

O the automation responds as established by dip switch No. 2.

5PRE-

FLASHING

On the pre-ashing function is enabled.

O the pre-ashing function is disabled.

6FOTOTEST

On the “photocell test” function is enabled.

O the “photocell test” function is disabled.

Note: to be used when the photocells are not used.

7MASTER/

SLAVE

On enables the MASTER mode in the master/slave conguration (see T-

COMM instructions).

O enables the standard operation (single motor) or SLAVE mode in the

master/slave conguration (see T-COMM instructions).

8BAR

LED

On when the boom is lifted all LEDs remain OFF.

O when the boom is lifted all LEDs behave as per setting of wire terminals

16-18 (default: FLASHING).

ENGLISH

19

9-10-11 Selection of barrier model and bar lenght

Dip 9 Dip 10 Dip 11 Modello

O O O LUXE-S bar ≥ 2 m ≤ 2,5 m

On O O LUXE-S bar > 2,5 m ≤ 3,5 m - RBLO-R 24 Vdc

O On O LUXE-S bar (with FPL) > 3,5 m ≤ 4 m

On On O LUXE-M bar > 3,5 m ≤ 5 m (elliptical boom) / ≤ 6 m (round boom)

O O On LUXE bar ≥ 4 m ≤ 4,5 m (including accessories)

On O On LUXE bar > 4,5 m ≤ 5,5 m (including accessories)

O On On LUXE bar > 5,5 m ≤ 6,5 m (including accessories)

On On On LUXE bar > 6,5 m (including accessories)

IMPORTANT: In case the boom length change, a new setting of the dips # 9, 10 and 11

will be required. Before the new setup, however, it is necessary to proceed to a HARD

RESET (see page 23) of the controller.

12 SENSITIVE EDGE

On RESISTIVE SENSITIVE EDGE (terminal No. 10).

O FIXED EDGE (NC contact – terminal No. 10).

Note: if not used, keep the DIP in the OFF position.

6. MEMORIZATION PROCEDURE

NOTE: Before starting the memorization procedure, make sure that the barrier boom is

perfectly balanced and that the mechanical limit switches of the boom are adjusted both in

opening and closing (see barrier assembly instructions).

WARNING: After powering the control panel, wait 2 seconds before you start performing the

adjustment operations.

When you have completed the installation procedures:

Check the position of dip-switches 9, 10 and 11. Dip-switches must be set according to the bar-

rier model and the bar length (see table of dip-switches 9-10-11, “Logic adjustments” section).

It is recommended to start the learning process with the bar down.

Press without releasing the PROG button till the DL8 LED starts ashing (yellow):

- the automation starts to open slowly looking for the opening limit stop;

If the automation closes instead of opening, stop the run of the gate (by cutting the pho-

tocells or closing the STOP contact), invert the polarity of the motor, take the gate in the

closed position (on the mechanical stop) and restart the procedure from the beginning.

Note: if the automation does not work, check the input connections. The DL6, DL5 and DL3

green LEDS must be on.

- once the limit stop is reached, the automation starts closing looking for the closing limit stop (in this

phase the control unit gathers all the parameters regarding the run);

- the automation carries out one complete opening to optimize the opening power;

- after a short pause, the automation carries out one complete closure to optimize the closing power.

WARNING:

- The procedure can be stopped by pressing the STOP button.

- During the various stages of the operation, if the sensor is activated saving is stopped. To

restart the procedure from the beginning (with the DL8 yellow LED ashing), use the AP/CH

control, the remote control (if programmed) or press the PROG button briey.

Please remember that an obstacle during saving is interpreted as a mechanical limit stop

(the system does not start any safety operation, it just stops the motors).

Make sure you don’t stand near the bar during saving.

ENGLISH

20

7. K206MA CHARACTERISTICS

TIMER-OPERATED OPENING AND CLOSING CYCLES

The opening/closing of the automation can be controlled by means of a timer that has a free N.O.

output contact (relay). The timer must be connected to terminals 4 - 6 (OPEN/CLOSE button) and can

be programmed so that, at the desired opening time, the relay contact closes until the desired closing

time (when the timer’s relay contact opens, enabling the automatic closing of the gate).

Note: the automatic closing function must be enabled by setting Dip-switch no. 1 to ON).

BATTERY CHARGER BOARD (INTEGRATED)

If the battery is connected the automation will operate in any case if there is no mains power supply.

If the voltage drops below 11.3 Vdc, the automation ceases to operate (the control unit remains fed);

whereas, when the voltage drops below 10.2 Vdc, the card completely disconnects the battery (the

control panel is no longer fed).

OBSTACLE DETECTION

Obstacle detection function that can be set using the FR trimmer: intervening during the automation

closing phase, it causes the total opening.

WARNING: the control panel logics may interpret mechanical friction as an obstacle.

8. DIAGNOSTICS LED

DL1 - Red OPEN button LED signal

DL2 - Red OPEN/CLOSE button LED signal

DL3 - Green STOP button LED signal

DL4 - Green CLOSE button LED signal

DL5 - Green PHOTOCELL LED signal

DL6 - Green SENSITIVE EDGE LED signal

LED - DL7

Apart from highlighting the presence of the battery, LED DL7 displays any mistakes with a series of

pre-set ashes in various colours:

Key: led always on; led ashing;

always on:

(green)fully-charged battery, main voltage present;

always on:

(yellow)battery charging;

1 ash every 4 seconds: fully-charged battery, no main voltage;

(green)Check the main voltage;

1 ash every 4 seconds::

(yellow)

power supply through photovoltaic panel (terminals 1-2), battery

charger disabled

1 ash every 2 seconds: low battery;

(red)Charge the battery, replace the battery;

fast ashing:faulty battery;

(red)Replace the battery;

LED - DL8

The DL8 LED indicates mistakes in the board logic with a series of pre-set ashes in dierent colours:

Key: led always on; led ashing;

1 ash every 4 seconds:

(green) normal operation;

ENGLISH

21

/ alternate ashing:

(red/green)saving to be performed;

fast ashing: (yellow) learning process;

1 ash: phototest error

(red) Disable phototest (dip-switch 6 OFF), check the operation of the photocells

and their connection;

1 ash: (yellow) unknown status, next operation REALIGNMENT;

2 ashes: obstacle for motor;

(red) Check there are no obstacles on the path of the bar and its balancing;

3 ashes: no motor encoder signal;

(red) Check wiring, check encoder by TEST-ENCODER (optional);

4 ashes: no motor signal;

(red) Check wiring, check the motor rotates freely and is powered directly by the

battery, check fuse F5;

5 ashes:max current limit for motor exceeded;

(red) Excessive absorption peaks of the gearmotor, check there are no obstacles on

the bar path, check the current absorption of the motor when in a no-load

condition and when applied to the bar;

6 ashes: master/slave communication error;

(yellow) Check wiring between the controllers, eciency of slave controller (fuses),

eciency of interface boards;

7 ashes (red): Sensitive edge safety intervention

A command pulse is required to carry out the closure;

8 ashes:Eeprom external memory fault;

(red) Replace the external memory module;

8 ashes:Eeprom data error (internal/external);

(yellow)Perform procedure RADIO MEMORY RESET;

Apart from the logic mistakes, the DL8 LED indicates also the status of the control unit during the sav-

ing of the radio controls.

always on: (green) channel CH1 waiting to be saved;

fast ashing: (green) CH1 channel memory full;

always on: (yellow)channel CH2 waiting to be saved;

fast ashing: (yellow)CH2 channel memory full;

ashing: (green)CH1 channel waiting to be cancelled;

always on: (green)cancelling of channel CH1 in progress;

ashing: (yellow)CH2 channel waiting to be cancelled;

always on: (yellow)cancelling of channel CH2 in progress;

When LEDs DL7 and DL8 ash at the same time they indicate:

ashing + : (red + red) factory reset procedure waiting for conrmation;

ashing + : (yellow + yellow) waiting for total cancellation of the radio channels;

Multiple errors are signalled by a 2-second pause between signals.

Should the encoder (obstacle detection) activates while closing, the controller will reverse the direction

and slowly open until the boom reaches its fully opened position. Auto Close function will be deactivated

until a further command pulse is given. In case of 5 consecutive safety interventions the controller will

progressively increase the Auto Close delay. Once the closing has been succesfully achieved, the Auto

Close delay will go back to standard setting.

ENGLISH

22

9. ABSORPTION CHECK FUNCTION (from 5.17 release onwards)

This function allows to monitor the absorption during a complete cycle in order to value the motor stress.

To activate this function press and hold for 2 seconds simultaneously CH1, PROG, CH2 and them start

the motor (OP/CL contact, remote, PROG button).

PROG

CH1

CH2

The absorption registered is shown according to the following diagram:

Level DL7 DL8

(Off) (Off)

(Green) (Off)

(Green) (Green)

(Green) (Yellow)

(Yellow) (Green)

(Yellow) (Yellow)

(Yellow) (Red)

(Red) (Yellow)

(Red) (Red)

After 5 minutes from the function activation, the board automatically resumes to the standard LED

visualization (to resume manually press simultaneously CH1, PROG and CH2).

10. RESTORING AUTOMATIC OPERATION

Should the Bar need to be operated manually, use the release system. After the manual operation:

• after a Mains Power Failure, such as a black-out (controller remains disconnected for a certain time),

the automation will be moving slowly to allow the Controller to establish its Limits (REALIGNMENT);

• after a Manual Operation without Mains Power Failure (controller remains connected) it will take 1

complete cycle to complete the realignment procedure. During this cycle, Limits and Soft-Stops will

not be working.

11. 433.92 MHz BUILT-IN RADIO RECEIVER

The radio receiver can learn up to a maximum of 30 rolling codes (S-2RP, S-4RP, K-SLIM-RP, T-4RP) which

can be set on the two channels as required.

The rst channel directly commands the control board for opening the automatic device; the second

channel commands a relay for a N.O. no-voltage output contact (terminals 19 - 20, max. 24V AC, 1 A).

LEARNING SYSTEM FOR RADIO CONTROL DEVICES

CH1 = OPEN/CLOSE CH2 = 2nd channel

1_ press button CH1 briey to associate a radio control device with the OPEN/CLOSE function;

2_ the (green) DL8 LED is ON to indicate the code learning mode has been activated (if no code is

entered within 10 seconds the board exits the programming function);

3_ press the button of the relative radio control device;

4_ the (green) DL8 LED turns o to indicate saving is complete and then on again immediately wait-

ing for other radio control devices (if this is not the case, try to re-transmit or wait 10 seconds and

restart from point 1);

5_ to memorise codes to other radio control devices, press the key to be stored on other devices

within 2-3 sec. After this time (DL8 LED turns o) must repeat the procedure from point 1 (up to a

maximum of 30 transmitters);

6_ if you wish to save on the 2nd channel, repeat the procedure from point 1 using the CH2 key instead

of CH1 (in this case the DL8 LED is yellow);

ENGLISH

23

7_ to exit the learning mode without memorising a code, press button CH1 or CH2 briey.

If the maximum number of radio controls is reached (30), the LED DL8 will begin to ash

rapidly for about 3 seconds but without performing memorisation.

REMOTE PROGRAMMING BY MEANS OF T-4RP, K-SLIM-RP, S-2RP AND S-4RP (V 4.X)

With the new version of software V 4.X it is possible to carry out the remote self-learning of the new version

of transmitters T-4RP, K-SLIM-RP, S-2RP and S-4RP (V 4.X), that is without pressing the receiver’s program-

ming buttons.

It will be sucient to have an already programmed transmitter in the receiver in order to start the

procedure of remote programming of the new transmitters. Follow the procedure written on the in-

structions of the transmitter T-4RP, K-SLIM-RP, S-2RP and S-4RP (V 4.X).

CANCELLING CODES FROM RADIO CONTROL DEVICES

1_ keep button CH1 pressed for 3 seconds in order to cancel all the associated radio control devices;

2_ LED DL8 ashes slowly to indicate that the cancellation mode has been activated;

3_ press button CH1 again for 3 seconds;

4_ LED DL8 turns o for approx. 3 seconds and then remains steady to indicate that the code has been

cancelled;

5_ repeat the procedure from point 1 using button CH2 to cancel all the associated radio control devices;

6_ to exit the learning mode without memorising a code, press button CH1 or CH2 briey.

MEMORY CAPACITY

The code memory capacity* can be expanded from 30 to 126, 254 or 1022 codes (transmitters) by replacing

the memory cards as follows

(plug them onto J3 connector, see wiring diagram)

:

126 codes Art. 250SM126

254 codes Art. 250SM254

1022 codes Art. 250SM1022

* Control units are supplied with a standard built-in 30-code memory. The memory card for enhancing the

code memory capacity must be ordered separately.

WARNING: Control unit must be turned OFF to insert / remove a memory card.

IMPORTANT: when a memory card is used, the control unit’s built-in 30 codes memory is disabled.

RADIO MEMORY RESET:

- press without releasing keys CH1 and PROG till LEDs DL7 and DL8 start ashing quickly with a yellow

light. At this point release the keys and press them again till the LEDs go o conrming the operation

is complete (if they are not pressed the board reverts to normal operation after about 12 seconds);

HARD RESET (factory setting):

- press without releasing keys CH2 and PROG till LEDs DL7 and DL8 start ashing quickly with a red

light. At this point release the keys and press them again till the LEDs go o (reset in progress),

conrming the operation is complete (if they are not pressed the board reverts to normal operation

after about 12 seconds); When the unit starts again saving will be required;

In case of Hard Reset the memory of the radio receiver will not be erased: all existing

transmitters remain programmed.

12. MALFUNCTIONS: POSSIBLE CAUSES AND SOLUTION

The automation does not start

a- Check there is 230V AC power supply with the multimeter.

b- Check, in the standard mode, that the NC contacts on the board are really normally closed (3

green LEDs on).

c- Set dip-switch 6 (phototest) OFF.

d- Increase the FR trimmer to the limit.

e- Check that the fuses are intact with the multimeter.

ENGLISH

24

The radio control has very little range

a- Check that the ground and the aerial signal connections have not been inverted.

b- Do not make joints to increase the length of the aerial wire.

c- Do not install the aerial in a low position or behind walls or pillars.

d- Check the state of the radio control batteries.

The gate opens the wrong way

Invert the motor connections on the terminal block, terminals 28 - 29 and terminals 23 - 24 (if used).

13. GUARANTEE: GENERAL CONDITIONS

TAU guarantees this product for a period of 24 months from the date of purchase (as proved by the

sales document, receipt or invoice).

This guarantee covers the repair or replacement at TAU’s expense (ex-works TAU: packing and trans-

port at the customer’s expense) of parts that TAU recognises as being faulty as regards workmanship

or materials.

For visits to the customer’s facilities, also during the guarantee period, a “Call-out fee” will be charged

for travelling expenses and labour costs.

The guarantee does not cover the following cases:

• If the fault was caused by an installation that was not performed according to the instructions

provided by the company inside the product pack.

• If original TAU spare parts were not used to install the product.

• If the damage was caused by an Act of God, tampering, overvoltage, incorrect power supply,

improper repairs, incorrect installation, or other reasons that do not depend on TAU.

• If a specialised maintenance man does not carry out routine maintenance operations accord-

ing to the instructions provided by the company inside the product pack.

• Wear of components.

The repair or replacement of pieces under guarantee does not extend the guarantee period.

In case of industrial, professional or similar use, this warranty is valid for 12 months.

ENGLISH

25

MANUFACTURER’S DECLARATION OF INCORPORATION

(in accordance with European Directive 2006/42/EC App. II.B)

Manufacturer: TAU S.r.l.

Address: Via E. Fermi, 43 - 36066 Sandrigo (Vi) - ITALY

Declares under its sole responsibility, that the product: Electronic control unit

designed for automatic movement of: Road barriers

for use in a: General environment complete with: Radioreceiver and battery charger board

Model: K206MA Type:K206MA

Serial number: see silver label Commercial name: Control panel for automatic barriers

Has been produced for incorporation on an access point (automatic barrier) of for assembly with other devices used to

move such an access point, to constitute a machine in accordance with the Machinery Directive 2006/42/EC.

Also declares that this product complies with the essential safety requirements of the following EEC directives:

- 2014/35/EU Low Voltage Directive - 2014/30/EU Electromagnetic Compatibility Directive

and, where required, with the Directive - 2014/53/EU Radio equipment and telecommunications terminal equipment

Also declares that it is not permitted to start up the machine until the machine in which it is incorporated or of which it will

be a component has been identied with the relative declaration of conformity with the provisions of Directive 2006/42/EC.

The following standards and technical specications are applied: EN 61000-6-2; EN 61000-6-3; EN 60335-1;

ETSI EN 301 489-1 V1.9.2; ETSI EN 301 489-3 V1.6.1; EN 300 220-2 V2.4.1; EN 12453:2000; EN 12445:2000; EN 60335-2-103.

The manufacturer undertakes to provide, on suciently motivated request by national authorities, all information pertinent

to the quasi-machinery.

Sandrigo, 24/01/2018 Legal Representative

_________________________________________

Loris Virgilio Danieli

Name and address of person authorised to draw up all pertinent technical documentation:

Loris Virgilio Danieli - via E. Fermi, 43 - 36066 Sandrigo (Vi) Italy

ENGLISH

Via Enrico Fermi, 43 - 36066 Sandrigo (VI) - Italy

Tel +39 0444 750190 - Fax +39 0444 750376

[email protected] - www.tauitalia.com

Foglietto illustrativo

CARTA - Raccolta dierenziata. Segui le indicazioni del tuo comune. (N.B.: togliere i punti metallici)

Instruction leaet

PAPER - Waste separation. Follow the instructions of your city hall. (Note: remove the staples)

22

PAP

Other manuals for K206MA

1

Table of contents

Popular Control System manuals by other brands

HALE

HALE SAM GENERATION 2 quick start guide

Johnson Controls

Johnson Controls Penn System 450 Series Technical bulletin

MBW

MBW CH104 Series Installation & user manual

Strand

Strand Vision.net RS232 user manual

Master

Master UNA Automation MIMI installation manual

FM

FM RG 311 Instruction manual and installation guide

Conviron

Conviron CMP6050 Operator's manual

Key Digital

Key Digital KD-FIX418A-2 operating instructions

Franke

Franke DVS UC07-001 Installation & operating instructions

Crestron

Crestron 4-Series AV4 quick start

NOBOCOOL

NOBOCOOL Ecohub user manual

Carrier

Carrier PRO-DIALOG PLUS 50AZ Installation, operation and maintenance instructions