Taurean B Series User manual

Taurean Door Systems Series B Roller Door Installation Instructions Page 1 of 2 Issue date 4th September, 2019

This document is only valid when supplied with a roller door or from a Taurean representative. Do not make copies. Contact Taurean (03) 9721 8366 for current version.

TAUREAN DOOR SYSTEMS

Series ‘B’ Roller Door

Installation Instructions

Customer Service (03) 9721 –8366 www.taureands.com.au

Extreme safety warning: Safe practices must be observed when working at heights, lifting roller doors and adjusting roller door spring tension.

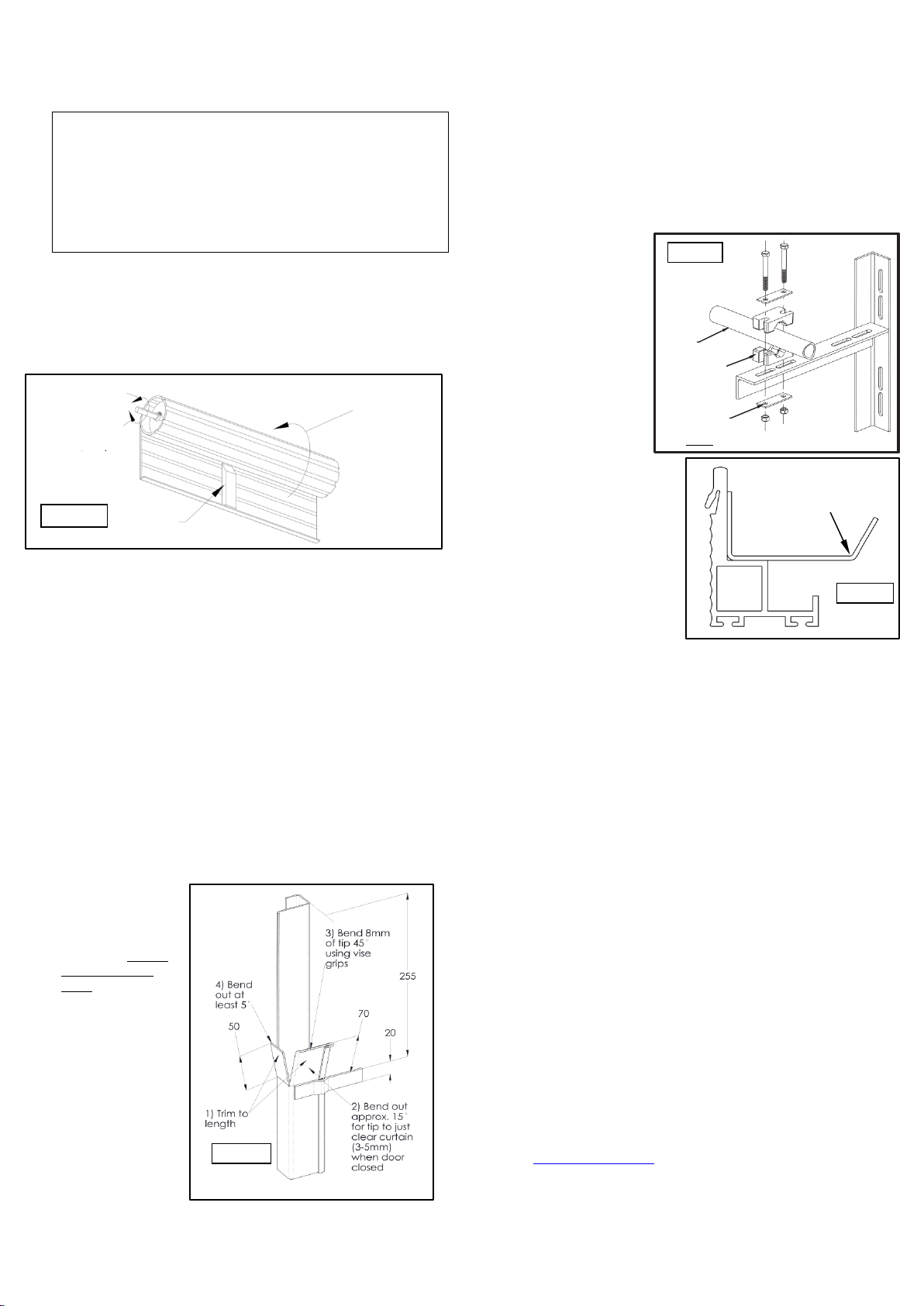

1. Check DOOR WIDTH against OPENING WIDTH (Figure 1). For a standard

(non-windlocked) installation the roller door curtain should be at least

100mm wider overall than the opening. For windlocked installation side

room increases by 35mm each side. For WINDSTRONG®refer to

supplemental instructions.

2. Check SIDE-ROOM (Figure 1). If a motor is to be installed, ensure there is

also enough clearance between edge of curtain and bracket (refer to

manufacturer’s instructions). Chain-operators (direct-drive or planetary-

gear) require 90mm MOTOR CLEARANCE and 195mm MOTOR SIDE ROOM.

Table 1

MOUNTING ROOM (mm)

A

B

C

D

E

2200

440

270

170

485

2500

455

275

180

505

2800

485

295

190

515

3100

495

300

195

525

3900

515

310

205

545

4600

550

325

225

575

5100

560

330

230

585

2200

440

270

170

485

3. Check the HEAD-ROOM B and BACK-ROOM E (Figure 2 and Table 1).

4. Mark the horizontal position for the wall brackets. They should be

positioned well clear of the curtain edge, guide tracks, and any track

brackets. The flanges normally point towards the roller door.

5. Mark the vertical position of the wall brackets above the opening (Figure 2

D). Level the two brackets at the door mounting faces using a water level

or other suitable device.

6. Attach the wall brackets to the wall:

Only self-drilling screws and wood fixing screws are supplied in the

kit box (no expanding or masonry bolts). The installer must assess

what is appropriate in each situation.

If welding installer must verify weld integrity and strength.

If screw fastened:

oFor steel purlins: four or more self-drilling screws must be

used to secure each bracket.

oFor timber frame: three or more 8mm x 50mm coach

screws must be used per bracket.

oFor brick or concrete: depending on the type and

condition of the wall, use three or more long M8 bolts (or

threaded rod) from the outer surface of the wall, or 10mm

(M8 thread) metal expansion fasteners (eg Loxin or

Dynabolt).

Flat washers must be used under all nuts and all bolt and screw

heads.

A screw or bolt must be fitted to the very top slot. Select other slot

positions evenly spaced up the bracket flange as required.

7. Option: mount motor loosely onto the axle at the required end (the

coloured side of the door faces outwards) with the drive disengaged.

8. If installing a chain-operator (direct-drive or planetary-gear), bolt the chain

wheel (or plastic ring gear) to the drum wheel at the correct end of the

door using the 3 bolts, nuts, and washers provided. If door is windlocked

the chain-operator is spaced 34mm further out from the drum wheel with

the 3 nylon spacers and longer fasteners provided. Re-fit the planetary

gear assembly into the ring gear.

9. Fit the chain-guide loosely to the axle, oriented with the tubes positioned

vertically in-line with the chain sprockets in the chain wheel. The clamp

screw is to be tightened only after final spring tensioning is completed.

10. For a planetary gear chain operator, the gear assembly and chain wheel is

pushed towards the door to fully mesh with the ring gear and a Ø9.5mm

hole is drilled through the axle using the drive hub as a guide. The chain

drive is fastened with the bolt and nut provided.

11. The chain itself may be fitted now or later. Pass the chain over the chain

wheel and through the chain guide. Cut an end link and bend it open to

join at the desired length, then bend it closed again. Fasten the chain cleat

to the drive-side wall.

12. Centre the axle by rotating a ¼ turn then releasing. Mark the axle where

the drum wheel sits in the relaxed state. There should be an equal length

of axle at each end.

13. Lift the roller door onto the brackets and loosely secure the axle to the

brackets using two cast saddles (with the slots offset towards the door),

keeper plates, and high-tensile bolts, nuts and washers at each end of the

door. The lower keeper plate is fitted under the bracket.

MOTOR-SIDE

ROOM

OPENING WIDTH

DOOR WIDTH = OPENING WIDTH + 100mm

Figure 1

(plan view)

PLAIN-SIDE ROOM

120mm MIN

MOTOR

CLEARANCE

Figure 2

C

D

Wall bracket top face

40 min

A

Opening

height

40 min

Bottom rail

B

Head

room

E

Backroom

Seal

Taurean Door Systems Series B Roller Door Installation Instructions Page 2 of 2 Issue date 4th September, 2019

This document is only valid when supplied with a roller door or from a Taurean representative. Do not make copies. Contact Taurean (03) 9721 8366 for current version.

Figure 3

Softwood

chock

Rotate axle to

increase

tension

Rotate axle to

decrease

tension

Final spring

tension: After

installation, adjust

door balance by

holding axle with

wrench, unclamp

axle, rotate axle

as required and

re-clamp.

Initial spring tension: rotate door one turn with

the door still strapped and the axle clamped tight

Top stop catcher bracket

Figure 6

Figure 5

Axle

pipe

Position cast

saddles with

slots offset

as shown

Lower saddle plate

goes under bracket

Extreme safety warning: Safe practices must be observed when

lifting roller doors as they can be very heavy. The installer must

ensure the roller door is secure and supported at all times. The

door is to be placed onto both brackets at the same time. The wall

brackets are designed to support only a horizontal door and using

them to mount door lifting gear is not recommended by Taurean.

Any injury or damage arising from this practice will be the

installer’s responsibility and is not covered by the door warranty.

14. Centre the roller door on the axle with the same amount of curtain overlap

at each side of the opening and position the motor. Rocking the roller door

on its axle will assist the door to move into position. Ensure the drum sits

on the axle as marked in Step 12.

15. Move the door to the rear of the bracket slots and, without cutting

through to the centre nylon strap, remove all other packaging material.

16. Turn the axle to allow the door to be relaxed on the axle with the bottom

rail at the bottom of the curtain (6 o’clock position). Hold the door and

give the axle a ½ turn of tension (see Figure 3). Fully tighten the axle

clamps.

17. Apply 1 turn of spring pre-tension by turning the curtain roll over the top

and hold in this position (Figure 3). There is now 1.5 turns of pre-tension.

18. Without letting go of the curtain, cut the centre strap and remove

packaging. Holding the centre of the bottom rail, the curtain may now be

fully opened and closed to ensure the roller door is rolling up in correct

alignment on the roll (ie, the ends of the rolled curtain must be square and

not ‘coned’) prior to fitting the Guide Tracks. Take care to avoid the nylon

braiding or the door curtain touching the wall.

19. The door should have a small amount of lift when in the open position and

so a softwood chock may now be carefully positioned (Figure 3) between

the Bottom Rail and the curtain roll to prevent the door rolling up.

20. Cut the bottom of the tracks to suit the opening height. The underside of

the top stop is normally level with the top of the opening (Figure 2). The

weather seal will protrude ~20mm into the opening when the door is

open. The top of the track should be at least 100mm above the wall

bracket.

21. Flare out and trim

both the side and rear

faces at the track lead-

in (Figure 4). Nick the

safety edge in two

places to allow

bending. After fitting

the tracks, if

necessary, adjust the

angles so the curtain

enters the track

smoothly. If the door

is installed high bend

the top edge of the

track away to avoid

catching the nylon

braiding.

22. Mount the tracks to the wall. Lower the door to the closed position and

slide the tracks in from the side until there is a 3-6mm gap between the

track and the black plastic button at the end of the Bottom Rail. Ensure the

tracks are vertical then fix to the wall by screwing or welding as

appropriate.

23. Note: Before fully fastening the tracks, operate the door fully to ensure it

is not binding in the tracks at any point.

24. Adjust the door-axle to the

optimal position on the

mounting brackets. Work

with the door in the open

position and only loosen one

end at a time. Loosen the

clamp and move the door

towards the wall until just

about touching the track

front face but avoiding any

binding. Ensure both clamps

are fully re-tightened. (Figure

5).

25. Install both of the optional

top stop catcher brackets (Figure 6)

at each end of the bottom rail using

the supplied dome-head bolt and

nut. Mark using the bracket as a

guide and drill.

26. Check the door balance:

When correctly balanced, the roller

door should have a tendency to lift

slightly at the top and bottom

positions and be neutral or slightly

heavy at mid height.

27. If necessary, adjust the springs (Figure 3):

With the door in the open position, loosen one clamp. Then, while

preventing the axle from turning with a pipe wrench, loosen the other

clamp. The handle of the wrench will want to lift towards the ceiling. Turn

the axle in the direction required to adjust the spring tension: raise the

wrench to make the door ‘heavier’, lower to ‘lighten’. This is a potentially

hazardous step and should only be attempted by a competent

tradesperson. Ensure both clamps are fully re-tightened before operating

door.

28. Complete motor installation and setup to the manufacturer’s instructions.

29. Fit the optional centre lock. Remove the protective film from this area,

position the lock front in the panel holes and hold or tape to the outside of

the door. From the back of the door, orient the lock with the writing the

‘right way up’ and screw to the lock front with the 2 screws supplied.

With the door in the fully closed position, mark the height positions of the

locking bar and cut a hole in each track for the locking bars to slide

through.

With the lock arms fully retracted, temporarily fit the 2 locking bars to the

lock arms then mark the correct length. Cut each bar to length and

chamfer-cut the corners for a lead-in. Then install the locking bars through

the PVC guides ensuring that any supplied anti-rattle grommets are fitted

and screw them to the lock arms. Check the lock operation.

30. Remove the protective film from the outside face of the curtain.

31. Fit the optional waist-high slide-lock at a suitable height. When withdrawn

the locking bar must not extend beyond the door curtain. Use the

assembly as a drilling guide and attach with the rivets provided. With the

door in the fully closed position, mark the height positions of the locking

bar and cut a hole in each track for the locking bars to slide through.

32. Refer to www.taureands.com.au for Product Warranty and Stramit Corp

Pty Ltd Roller Door Warranty and Exclusion of Liability Statement

Figure 4

Popular Door Opening System manuals by other brands

wink haus

wink haus FM.A operating instructions

GFA

GFA ELEKTROMAT ST 80.15-50,00 installation instructions

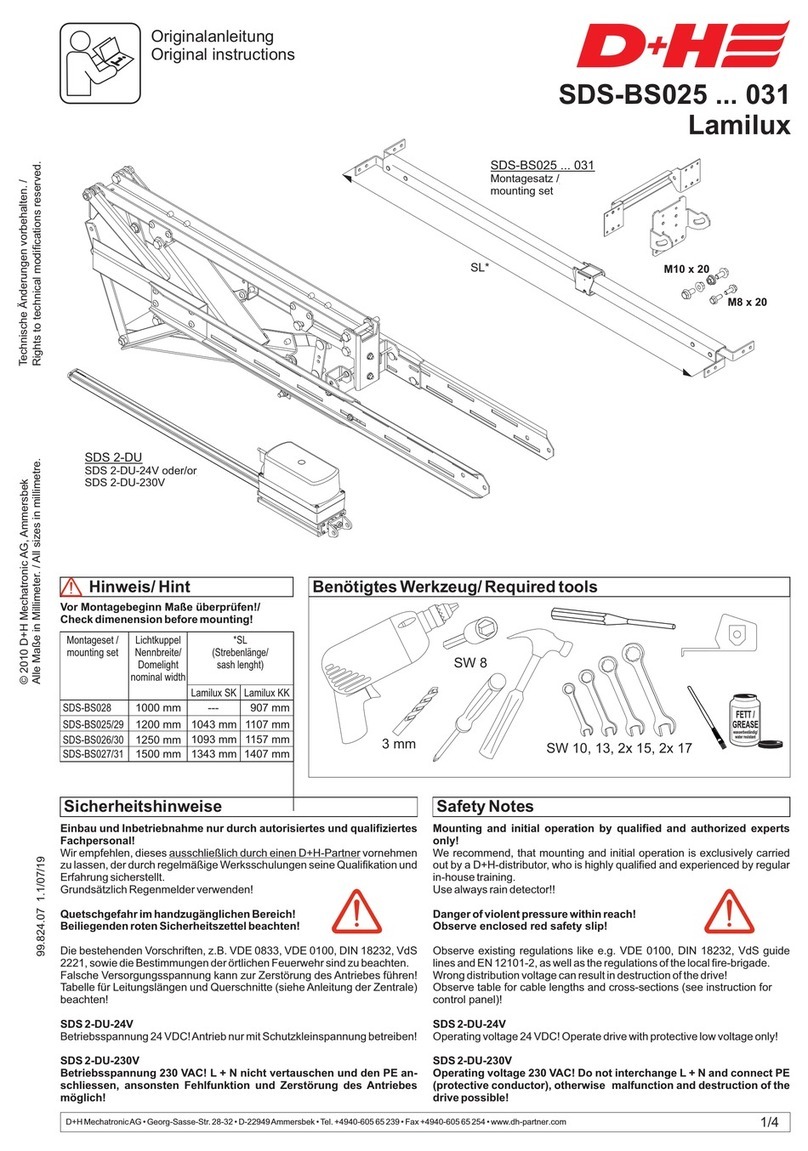

D+H

D+H Lamilux SDS-BS025 031 Series Original instructions

Relcross Door Controls

Relcross Door Controls 4040XP.TANDEM.61.US28 installation instructions

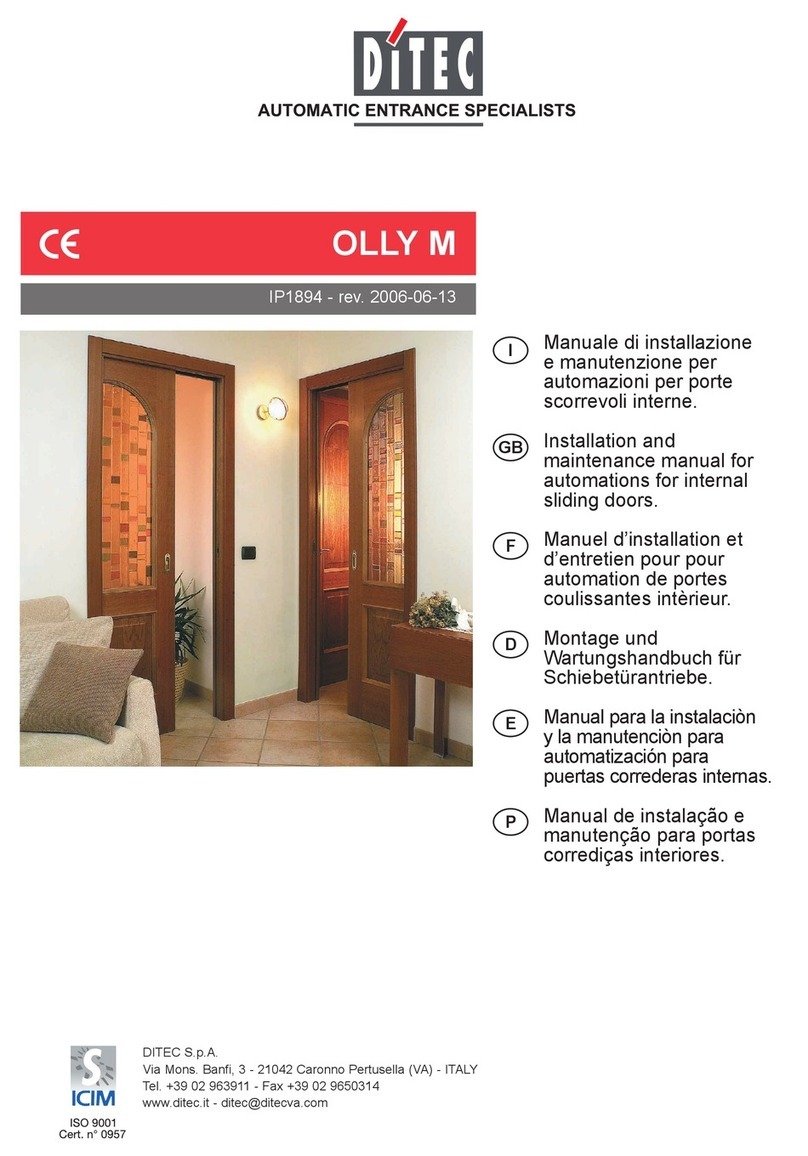

DITEC

DITEC OLLY M Installation and maintenance manual

Inotherm

Inotherm InoSmart manual

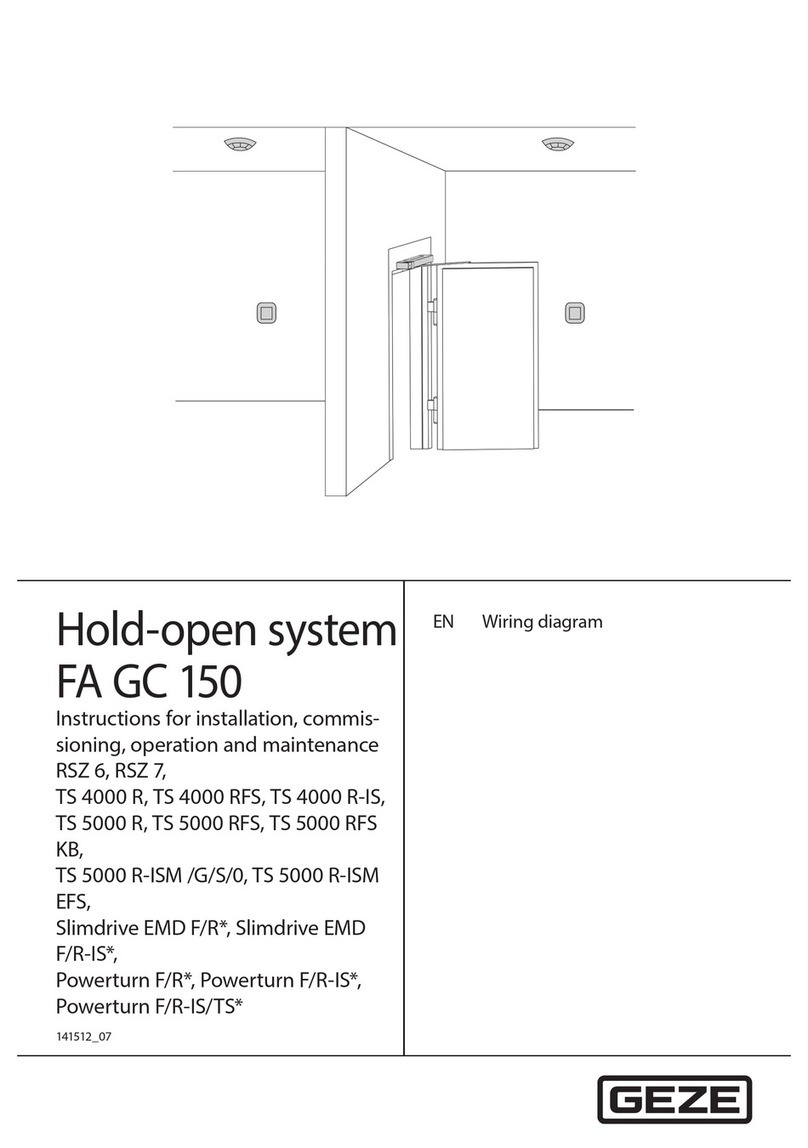

GEZE

GEZE FA GC 150 Instructions for installation

PDQ

PDQ 6300M/MF Installation instruction

Bohle

Bohle Verifix 638.0 operating instructions

Dormakaba

Dormakaba 1856 HT SD installation instructions

CDV Group

CDV Group DIGIWay DWS102 Series Use and installation manual

WebDoor

WebDoor CADET PRO Installation and instruction manual