tbs electronics SHURCut 2500 User manual

®

A Division of General Data Healthcare

Histology Innovation for a NEW Generation

Operator’s Manual

Product Name

Here

SHURCut™ 2500 Microtome

Semi-Automated Rotary Microtome

Catalog #

SC2500

Pub No.: OM SC2500-1

October 2013

SC2500

3 | Page

General Data Healthcare, Inc.

Copyright©2009 General Data Company. All rights reserved

This document may not be copied in whole or in part or reproduced in any other media without the express

written permission of TBS-A Division of General Data Healthcare, or General Data Healthcare. Please note

that under copyright law, copying includes translation into another language.

General Data Healthcare TBS-A Division of General Data Healthcare

Corporate Headquarters 3014 Croasdaile Road

4354 Ferguson Drive Durham, NC 27705

Cincinnati, Ohio 45245 tel. 919-384-9393

Tel. 513-752-7978 Fax. 919-384-9595

Fax.513-965-3636

User Resources and Customer Support

Contact your TBS representative for customer support. For the latest information on TBS products and services,

please visit the TBS website at: www.trianglebiomedical.com.

Scope

This document contains basic information on the use and operation of a SHURCut™ 2500 Microtome and assumes

you have received basic training on the instrument. Please contact your TBS representative for information not

provided in this manual.

Intended Use

The SHURCut™ 2500 Microtome is designed to section embedded specimens with up to .5 micron precision to

provide best possible samples in the field of histology.

Installation Procedure

The SHURCut™ 2500 must be installed, and instrument performance is to be verified, at the customer site by

trained TBS representatives.

Disclaimers

This manual is not a substitute for the detailed operator training provided by TBS, or for other advanced instruction.

A TBS representative should be contacted immediately for assistance in the event of any instrument malfunction.

4 | Page

General Data Healthcare, Inc.

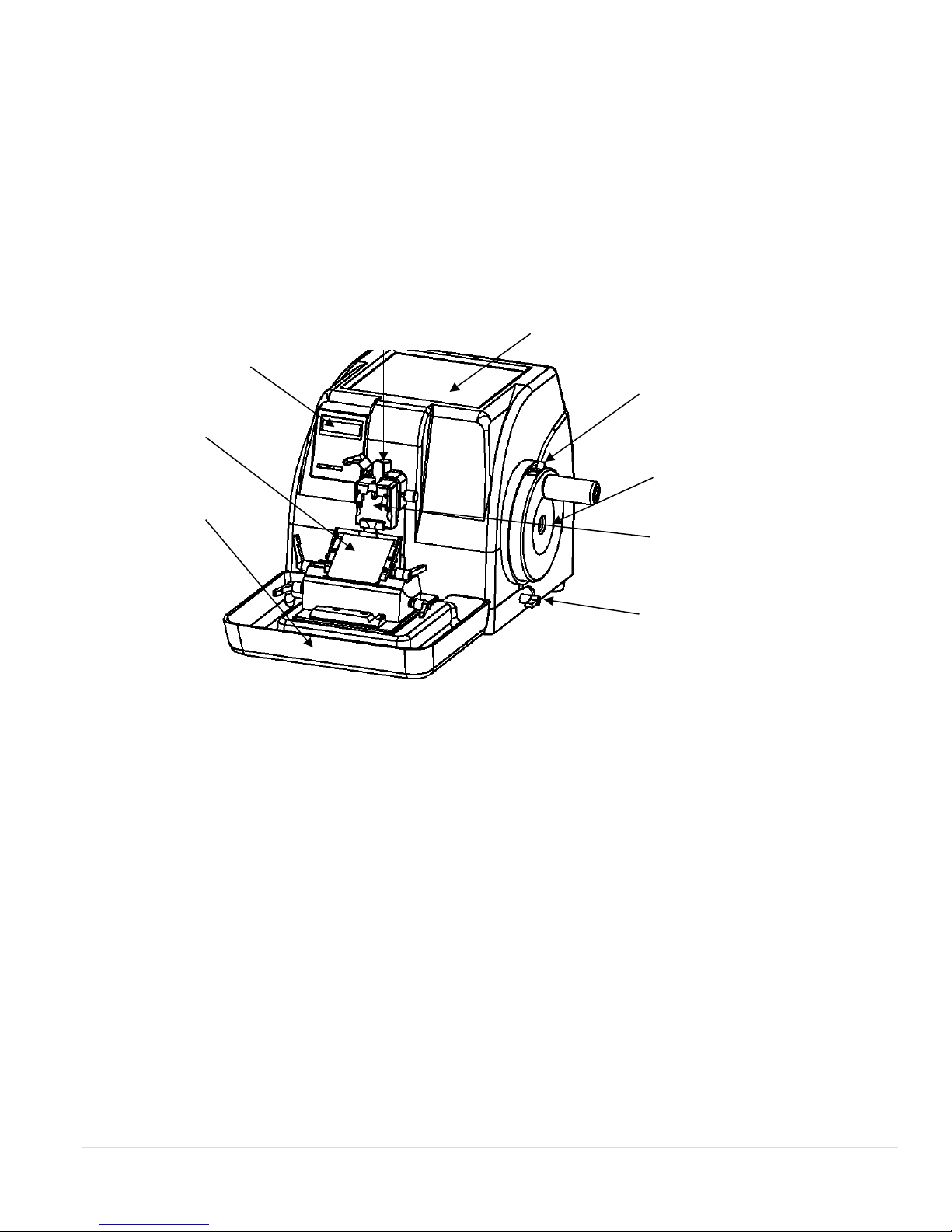

Operator Controls and Components

Operator’s hand wheel

Hand wheel locking mechanism

Lever for 360° hand wheel

brake

Section waste tray

Blade holder

Display panel

Storage Tray

Quick-Release cassette clamp

Clamp Adjuster

5 | Page

General Data Healthcare, Inc.

Table of Contents

Operator Controls and Components....................................................................................................... 4

Declaration of Conformity....................................................................................................................... 6

Instrument Compliance............................................................................................................................ 7

Section1 | Safety Instruction .................................................................................................................... 8

Summary.........................................................................................................................................................................8

Safety Notes....................................................................................................................................................................8

Safety Devices................................................................................................................................................................9

Section 2 | Specifications......................................................................................................................... 10

Technical Data..............................................................................................................................................................10

Section 3 | Preparation.............................................................................................................................11

Installation Site Requirements......................................................................................................................................11

Standard Accessory List.............................................................................................................................................11

Installation....................................................................................................................................................................12

Blade Holder.............................................................................................................................................................12

Waste Tray................................................................................................................................................................12

Electrical Connection ...................................................................................................................................................13

Section 4 | Operation............................................................................................................................... 14

Control Panel and Its Features......................................................................................................................................14

Display Panel............................................................................................................................................................14

Blade Holder.................................................................................................................................................................16

Specimen Clamping System.........................................................................................................................................17

Clamping the Specimen and Blade Installation............................................................................................................18

Activating Trimming ....................................................................................................................................................19

Activate Sectioning.....................................................................................................................................................19

Section 5 | Cleaning and Maintenance.................................................................................................. 21

Cleaning the Clamp......................................................................................................................................................21

Cleaning the Blade Holder: ..........................................................................................................................................22

Section 6 | Troubleshooting .................................................................................................................... 23

6 | Page

General Data Healthcare, Inc.

Konformitätserklärung

Déclaration de conformité

Declaración de Confomidad

Verklaring de overeenstemming

Dichiarazione di conformità

We/Wir/ Nous/WIJ/Noi

TBS-A Division of General Data Healthcare.

Declare under our sole responsibility that the product,

erklären, in alleniniger Verantwortung,daß dieses Produkt,

déclarons sous notre seule responsabilité que le produit,

declaramos, bajo nuestra sola responsabilidad, que el producto,

verklaren onder onze verantwoordelijkheid, dat het product,

dichiariamo sotto nostra unica responsabilità, che il prodotto,

SHURCut™ 2500 Semi-Automated Rotary Microtome

to which this declaration relates is in conformity with the following standard(s) or other normative documents.

auf das sich diese Erklärung bezieht, mit der/den folgenden Norm(en) oder Richtlinie(n) übereinstimmt.

auquel se réfère cette déclaration est conforme à la (aux) norme(s) ou au(x) document(s) normatif(s).

al que se refiere esta declaración es conforme a la(s) norma(s) u otro(s) documento(s) normativo(s).

waarnaar deze verklaring verwijst, aan de volende norm(en) of richtlijn(en) beantwoordt.

a cui si riferisce questa dichiarazione è conforme alla/e seguente/i norma/o documento/i normativo/i

Declaration of Conformity

7 | Page

General Data Healthcare, Inc.

Instrument Compliance

TBS-A Division of General Data Healthcare hereby declares the equipment specified conforms to the Classification(s),

Directive(s) and Standard(s) set forth in this document.

Certifications: CE, TUV

EMC Emissions

FCC 47 CFR Part 2, Part 15 CISPR PUB.22 (USA)

EMC Immunity:

EN 55011:2007: (Class B), EN 61000-3-2:2006/A2:2009, EN 61000-3-3:2008, EN 61326-1:2006

IEC 61000-4-2:2008, IEC 61000-4-3:2010, IEC 61000-4-4:2010, IEC 61000-4-5:2005, IEC 61000-4-6:2008

IEC 61000-4-8:2009, IEC 61000-4-11:2004

EN 61010-1: (Third Edition) :2001, EN61010-1:2010

8 | Page

General Data Healthcare, Inc.

Section1 | Safety Instruction

Summary

This instrument was built and tested in accordance with the safety regulations as specified below:

Gb9706.1-1995 medical electricity equipment

Note

:

Safety instruction labels on the instrument must be kept in the original place to

avoid an accident, personal injury, or damage to the instrument.

Safety Notes

The following instructions are regarding the transport, installation, regulation, operation

and maintenance of the instrument which must be read and complied with.

Warnings-Transport and Installation

The instrument may only be transported in an upright position.

Never lift the instrument by the hand wheel or the cassette clamp. Always

remove the section waste tray and blade holder before transporting the

instrument.

Check to make sure that the voltage available at your facility complies with the

requirements of this unit.

Connect the unit using the power cable provided. It is critical to connect to a

grounded socket.

Do not operate in rooms with explosion hazards.

Do not tamper with the safety devices of the unit.

Warnings-Working with the Instrument

Take great care in handling microtome blades. The cutting edge is extremely

sharp and can cause serious injury.

Always remove the blade and put in a safe location before detaching the blade

holder from the unit.

Always clamp the specimen block before inserting or clamping the blade.

Always keep the hand wheel locked when handling the blade or specimen on

the unit. Cover the cutting edge with the blade guard.

9 | Page

General Data Healthcare, Inc.

Place the blade guard over the blade when sectioning.

Make sure that liquids do not enter the interior of the instrument.

1.2.3 Warnings-Cleaning and Maintenance

Only authorized and qualified service personnel may access the internal

components of the instrument for service and repair.

Before each cleaning, switch the unit off, disconnect the power plug, and

remove the blade holder completely and clean it separately.

Lock the hand wheel before each cleaning.

Do not use any solvents containing acetone or xylene for cleaning.

Make sure that liquids do not enter the interior of the instrument when

cleaning.

Let the unit dry completely before powering up again.

Turn the unit off and disconnect the power plug before replacing fuses. Only

use fuses of the same specification and replace them as described in the

manual.

Safety Devices

Handwheel Locking Mechanism

There are two handwheel locking mechanisms.

•Locking mechanism indicated by (1) on the

diagram can be engaged by flipping the

corresponding switch and rotating the hand

wheel to the upper most position where it will

lock into position.

•Locking mechanism indicated by (2) on the

diagram can be engaged in any position of the

handwheel by rotating the handle 180°

clockwise. To unlock, rotate 180° counter

clockwise.

Do not lock the handwheel (1) when the handwheel is rotating as it will

damage the unit.

Whenever cleaning the unit, changing the specimen, or changing the blade,

make sure the handwheel is locked with either mechanism (1) or (2).

1

2

10 | Page

General Data Healthcare, Inc.

Blade guard

•Position the blade guard (3) over the blade

when not operating the unit to avoid personal

injury and prevent damaging the blade edge.

•The blade guard(3)in Fig is shown in the up

position where it protects the blade.

Section 2 | Specifications

Technical Data

SC2500

Item:

Description:

Dimensions

Length: 21.6 in (55 cm)

Width: 16.5 in (42 cm)

Height: 12.6 in (32 cm)

Weight:

92 lbs. (42 kg)

Environment requirements:

Working temperature

:

+10

℃

—40

℃

Working humidity: <80%

Working pressure:

(

86

~

106

)

kpa

Power Supply:

110/220 v ac±10 %

Frequency:

50/60 Hz

Fuse:

1.5 Amps

Safety Classification:

I - Type b

Blade Profile

Low Profile Blade – Recommended, DMB-LP SHUR/Sharp™

Disposable Microtome Blade, Low Profile, Teflon Coated; (0.012”

x 0.312” x 3”

Trimming/Section

Thickness:

0.5 to 600µm

0.5 to 2µm - 0.5µm increments

2 to 10µm - 1µm increment

10 to 20µm - 2µm increments

20 to 100µm - 5µm increments

100 to 600µm - 50µm increments

3

11 | Page

General Data Healthcare, Inc.

SC2500 (cont.)

Item

Description

Retraction thickness:

20µm

Specimen horizontal feed:

20mm

Specimen vertical feed:

70mm

Maximum specimen size:

40mm x 50mm x 30mm or standard cassette size

Specimen holder

adjustment system:

Horizontal orientation: ±8°

Vertical orientation

:

±8°

Left/Right Blade holder

adjustment:

50mm

Section 3 | Preparation

Installation Site Requirements

Place the unit on a well-supported table. Ensure the table is sitting level.

Ensure that the operating temperature and humidity is according to spec.

Ensure that there is nothing obstructing the handwheel operation.

Standard Accessory List

Part:

Quantity:

Microtome

1

Blade holder

1

Quick Release Clamp for Standard Cassette

1

Waste Tray

1

M3 Wrench

1

M4 Wrench

1

Disposable Blades

1

Fuse

2

Operation Manual

1

12 | Page

General Data Healthcare, Inc.

1

2

3

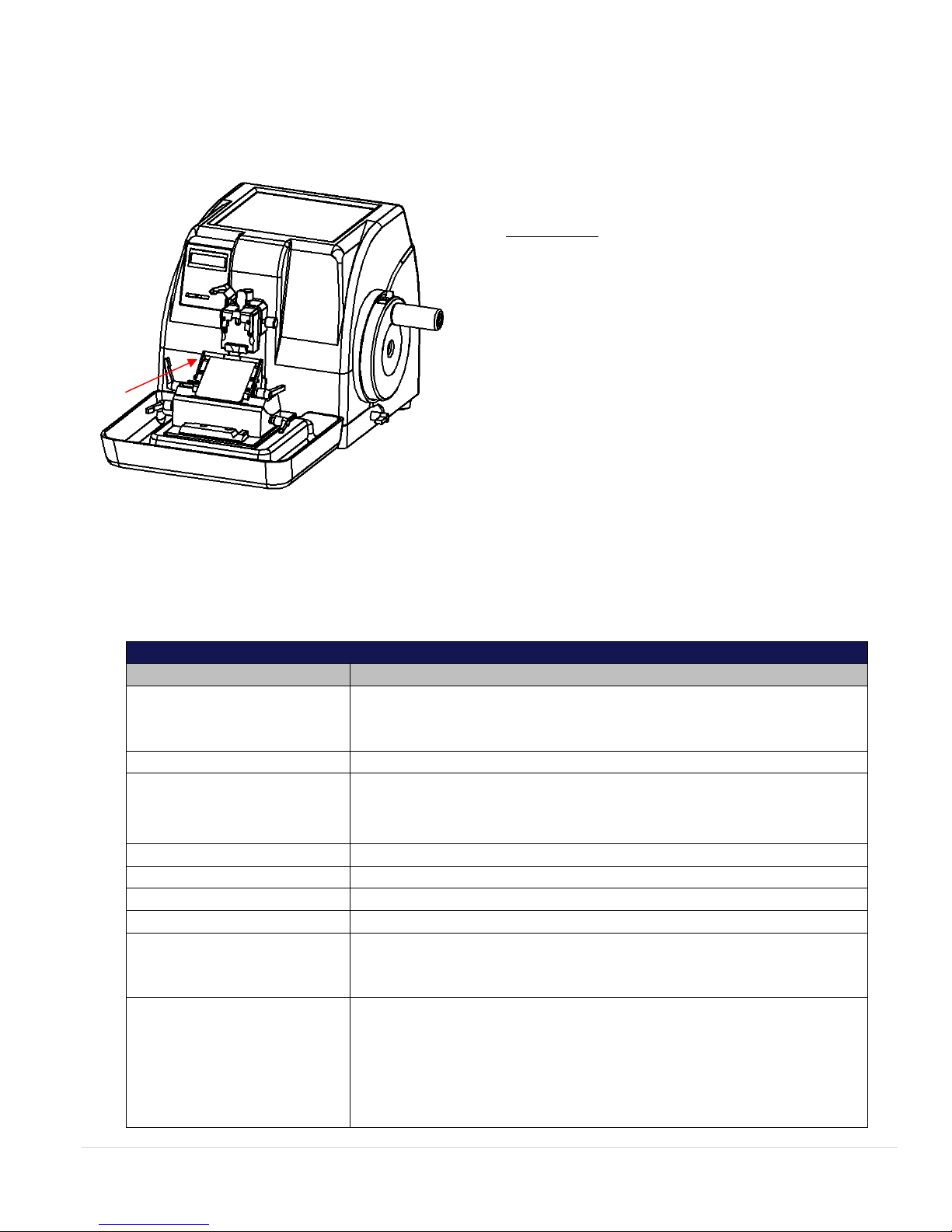

Installation

Blade Holder

Remove the blade holder (1) from the box, and

push it along the track as it is showed in the

picture, and then rotate the blade holder locking

lever (2) to lock the blade holder.

Waste Tray

Remove the waste tray (3) out from the box and

push it along the track as it is showed in the picture.

13 | Page

General Data Healthcare, Inc.

4

5

6

Electrical Connection

Check to make sure that the voltage available at your facility complies with the

requirements of this unit.

Connect the unit using the power cable provided. It is critical to connect to a

grounded socket.

Before changing a fuse, make sure to disconnect power from the unit.

1. Insert the fuse (6) into the fuse socket (5) as it is

showed in the picture and the insert the whole fuse

socket into the socket (4).

2. Energize the equipment with the switch at

the rear right side. The instrument should

initialize.

3. After the microtome is energized, the display

field in the control panel will illuminate. The

specimen holder will automatically retract

back to zero. This is followed by a beep.

14 | Page

General Data Healthcare, Inc.

Section 4 | Operation

Control Panel and Its Features

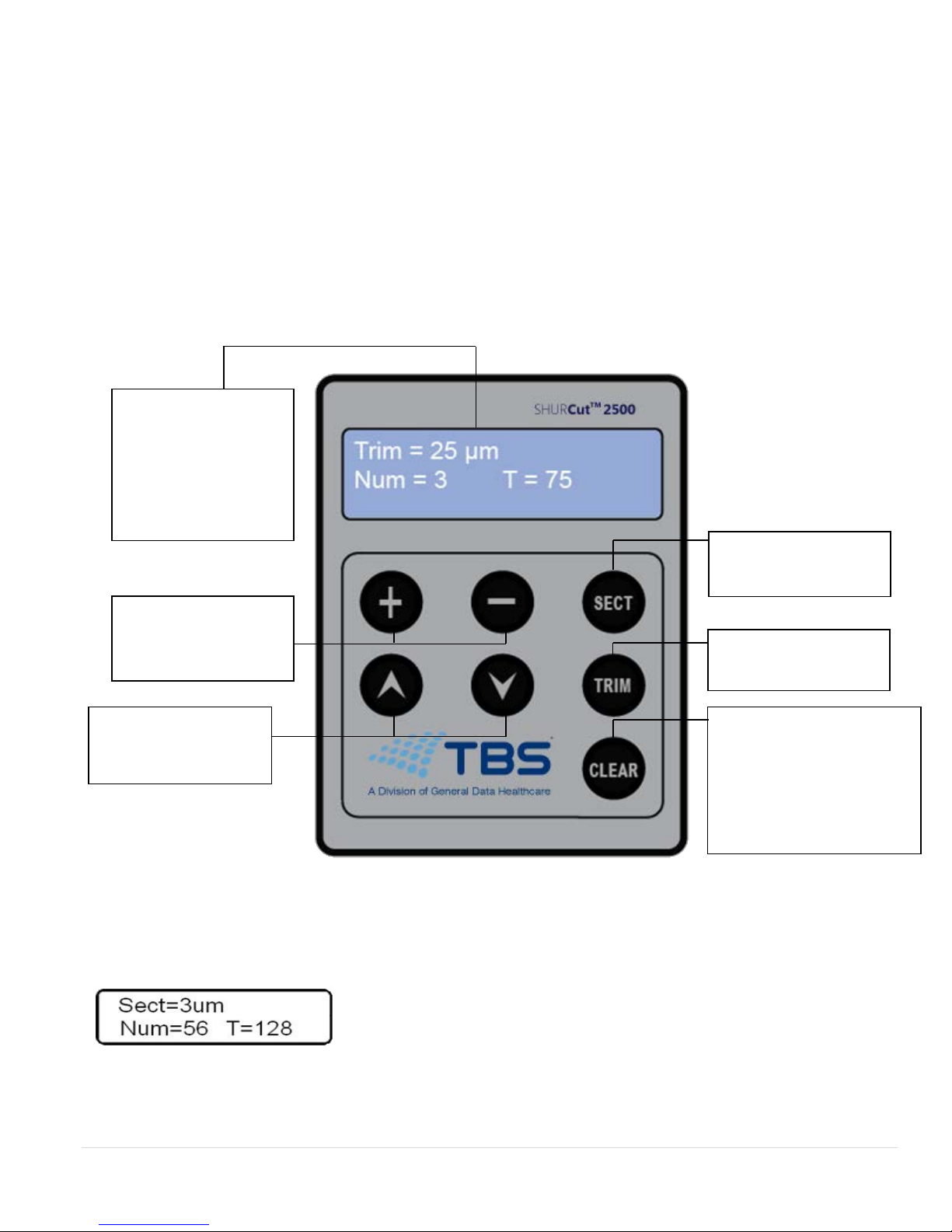

All the parameters are set and displayed via the control panel. After being energized, use the control

panel to operate the instrument, the following is a diagram explaining the functions of the control

panel.

Display Panel

•The value in the first line of the display window is the set

sectioning or trimming thickness.

The value in the second line of the display window is the

section or trim counter and section or trim thickness sum (total

advance).

•The system is in trimming mode after energize the

instrument.

LCD display: section

thickness / trimming

thickness; section

counter & total

sectioned amount

Buttons for setting

section thickness and

trimming thickness

Coarse feed

Backwards / Forwards

The button activates

the sectioning mode

The button activates

the trimming mode

Button to clear the display

parameters to 0:

1. section counter

2. section thickness sum

15 | Page

General Data Healthcare, Inc.

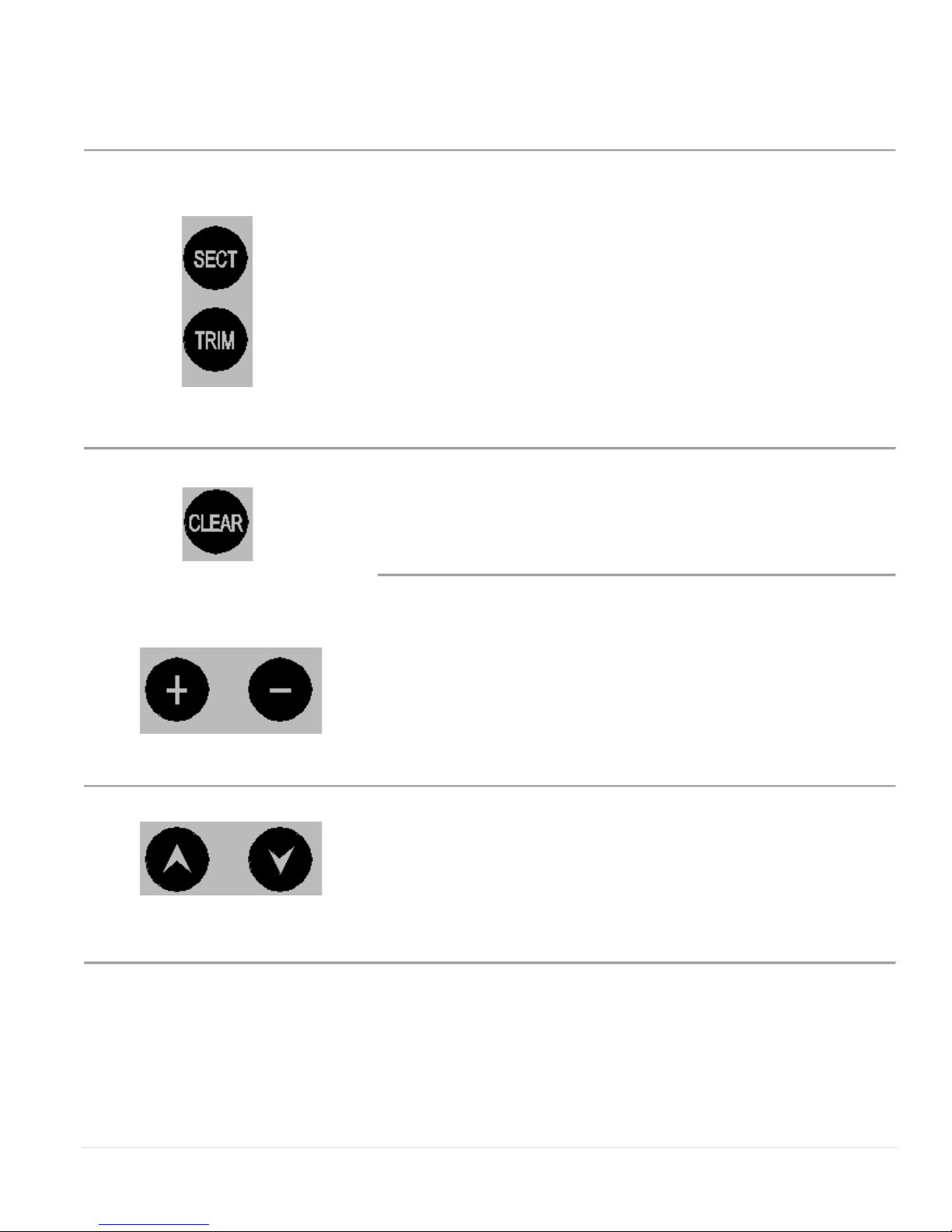

SECT Button

•SECT button activates the sectioning mode. The first line on the

display will show [SECT=]. Used to adjust section thickness

TRIM Button

•TRIM button activates the trimming mode. The first line on the

display will show TRIM=. Used for setting the TRIM thickness

•When the unit is powered on, it will display the last set value for

the section or trimming mode.

•Pressing the CLEAR button will clear the section / trimming counter

and the thickness sum (total advance).When the instrument is

energized, the value of the section counter and section thickness sum

will automatically go back to zero.|

•Press the + (plus) button or – (minus) button to set the section or trim

value.

Adjusting range: 0.5 to 600µm

0.5 to 2µm,0.5µm increments

2 to 10µm,1µm increment

10 to 20µm,2µm increments

20 to 100µm,5µm increments

100 to 600µm,50µm increments

•The arrow buttons control the forward and backward direction of the

arm that holds the specimen. The advance and retract speed is

750µm/s.

•The max forward and backward distance is 20mm. If the maximum

distance is exceeded, the specimen holder will stop moving and an

alarm will sound.

16 | Page

General Data Healthcare, Inc.

Blade Holder

•The blade holder consists of the blade holder base

(2), X-axis slider (3), and the blade holder clamp

(4).

•The whole assembly sits on the base plate (1)

attached to the microtome.

•The X-axis slider (3) allows for 10 degrees of

adjustment of the blade with respect to the specimen.

•The pictures below explains which component each

lever locks.

Always remove the blade first before detaching any of the components of the blade

holder assembly.

Always make sure that all 4 levers on the blade holder are tight before using the

microtome to avoid potentially ruining a specimen sample.

The lever on the left operates

the blade holder clamp.

The lever on the right

operates the X axis slider

clamp.

The lever on the left operates

the Y axis slider clamp.

4

2

1

3

17 | Page

General Data Healthcare, Inc.

Specimen Clamping System

•To actuate the specimen holding arm (1), rotate the

handwheel (2) clockwise.

•The specimen clamping system comes with two separate

clamps:

oQuick Release Clamp (5):

Dimension of Specimen:

40mm x 50mm x 30mm or the standard

cassette size.

oC-Type Clamp (6) (Optional Accessory):

Dimension of Specimen:

Accepts standard cassette size as well as any

specimen carrier that is less than 40mm in

length/width. The clamp will also accept

carriers as small as 12mm in length/width.

•The clamps (5 or 6) attach to a connector (4) which

attaches itself to the adjuster (3).

•To attach a clamp, first attach the connector (4) to the

adjuster (3) using four screws. Then attach either the

Quick Release Clamp using two screws or the C-Type

Clamp using four screws.

•The specimen clamp adjustor allows for the specimen to

be swiveled in the horizontal and vertical direction:

oHorizontal orientation: ± 8°

oVertical orientation:±8°

•To make an adjustment, first loosen the lever (7). Next,

you are able to either adjust the vertical orientation using

the knob on top (8) or the horizontal orientation using the

knob of the right side (9). After the adjustments are made,

retighten the lever(7).

1

2

6

4

5

3

8

7

9

18 | Page

General Data Healthcare, Inc.

Clamping the Specimen and Blade Installation

Clamping the specimen:

•Using the C-Type Specimen Clamp:

oPut the specimen (4) into the clamp (1) as is

shown in the picture. Then rotate the nut (3)

clockwise to tighten the clamp. To remove

the specimen, rotate the nut

counterclockwise.

•Using the Quick Release Clamp:

oPull the clamp handle (5) in the direction

showed in the picture. The clamp will open.

You can now insert the specimen (6) into the

clamp (2). Release the handle (5), the

specimen will be clamped automatically. To

remove the specimen, repeat the same

operation.

Always clamp the specimen

first before installing the blade

to avoid injury.

Installing the blade:

•Before installing the blade in the blade holder

clamp, make sure that the blade holder base is

secured (9). Then, choose the angle of the X-Axis

slider and secure it using lever (10). Choose the

lateral location of the blade holder clamp and

secure it using lever (8). Finally, place the blade

in the blade holder clamp as shown by the red

arrow (11) and secure it using lever (7).

1

3

4

2

6

5

8

10

9

7

11

19 | Page

General Data Healthcare, Inc.

Activating Trimming

•To activate the trimming mode, press the button. The screen

will display the set parameters of trimming.

•To set the trim thickness, press the button. The screen will

display the trim thickness value.

•Press the directional buttons to adjust the specimen

forward and back to ensure the specimen is lined up with the

cutting edge.

•Finally, make sure the levers that secure the blade holder are all

tightened. The unit is now ready to section. Unlock the handwheel

and begin to rotate it clockwise to section.

Activate Sectioning

•To activate the SECT mode, press the button and the

instrument goes into sectioning mode, and the screen will display

the set parameters of sectioning.

•Press the buttons to set the sectioning thickness value.

20 | Page

General Data Healthcare, Inc.

•To obtain optimum quality sections, the following factors need to be taken into consideration:

a. The hardness of the specimen

b. The angle of the cutting blade

c. The blade is clamped tightly

d. The specimen is clamped tightly.

•To obtain a quality section, first adjust the proper angle of the cutting blade and the specimen:

a. The smaller the angle, the less the section will be compressed.

b. The harder the specimen, the larger the angle will be needed.

c. If the section is not good, try increasing the angle from zero.

When finished sectioning, turn the handwheel until the specimen is in the upper most

position, lock the handwheel, remove and safely dispose of the blade.

This manual suits for next models

1

Table of contents

Other tbs electronics Laboratory Equipment manuals